Best Practices in Decorating Empty Mascara Tubes

Empty mascara tubes don’t seem like much at first glance—just plastic shells waiting for a swipe of glamour. But in the beauty biz, they’re your billboard on the shelf. That tiny cylinder? It’s working overtime, whispering your brand’s whole story before a customer even opens the cap.

Now here’s the kicker: not all decoration methods are created equal. Go too cheap and flimsy, and you’ll end up with peeling labels or faded logos that scream “afterthought.” Go overboard, and production costs balloon faster than an influencer’s follower count.

“Custom molds paired with UV coatings can increase shelf retention by up to 37%,” says Lena Wu, Senior Packaging Engineer at Topfeel (2024 Q1 Internal Report). Translation: investing wisely in design keeps your product—and brand—on people’s minds longer.

So buckle in—we’re about to break down what works (and what flakes) when dressing up empty mascara tubes for mass-market charm and staying power.

Reading Notes on Styling Empty Mascara Tubes with Staying Power

→ Custom Mold Designs: Unique tube shapes attract attention and reinforce brand identity, increasing product recall on shelves.

→ Hot Stamping Decoration: Adds elegant metallic finishes that elevate perceived value and attract premium buyers.

→ Silk Screen Printing: Delivers vibrant, durable colors that resist wear and maintain visual appeal over time.

→ Label Application Services: Offers a flexible, cost-effective way to communicate branding and product info.

→ UV Coating Finishes: Prevent fading and protect designs, extending shelf life and preserving brand aesthetics.

→ Eco-Friendly Paperboard Packaging: Appeals to sustainability-minded consumers and aligns your brand with green values.

→ Child-Resistant Closures: Enhance product safety, meet compliance requirements, and boost consumer trust.

→ Wholesale Networks: Lower per-unit costs and allow for scalable growth through bulk purchasing.

Why Decorate Empty Mascara Tubes?

A little flair on your lash product goes a long way—especially when the tube itself grabs attention before the brush even hits your lashes.

Stand Out on Empty Mascara Tubes with Custom Mold Designs

• A bold silhouette makes people stop scrolling. Custom molds help your product pop off shelves and screens alike.

• Unique shapes like twisted barrels or gem-cut finishes build instant brand recall—no extra marketing needed.

• Going beyond standard cylinders? That’s where real differentiation starts.

Rounded, squared, or asymmetrical—when you apply custom mold magic to your packaging, you’re not just selling mascara; you’re offering an experience. These design tweaks turn basic cosmetic containers into branded statements that shout personality.

Topfeel nails this by crafting standout packaging that feels both premium and playful.

Drive Bulk Orders through Mascara Tubes Wholesale Networks

Grouped benefits of wholesale mascara tube sourcing:

- Bulk Orders = lower per-unit cost, higher margin possibilities

- Access to global-scale Wholesale Networks, ensuring consistent supply

- Easier integration into larger-scale Distribution pipelines

- Streamlined logistics within the beauty product Supply Chain

Working directly with manufacturers means skipping middlemen and locking down competitive pricing for large quantities of lash containers. That’s how indie brands scale fast without burning budgets.

Appeal to Eco-Conscious Consumers via Eco-Friendly Paperboard Packaging

(Scientific Table triggered)

| Packaging Type | Material Composition | Recyclability (%) | Biodegradability Rating |

|---|---|---|---|

| Paperboard Sleeve | FSC-certified Kraft | 98 | High |

| Corrugated Insert | Recycled Pulp | 90 | Medium |

| Laminated Carton | PE-coated Cardstock | 45 | Low |

| Molded Fiber Tray | Bamboo Blend | 92 | Very High |

Eco-minded shoppers aren’t just looking at ingredients—they’re checking what the tube comes wrapped in too. Using biodegradable or recyclable materials for outer boxes gives your brand instant green points. And it’s not just about saving trees—it’s about showing values align with your audience’s.

Enhance Safety with Child-Resistant Closures on Mascara Tubes

Short insights that matter:

• Parents want peace of mind when makeup bags are within toddler reach.

• Adding a secure twist-lock cap reduces accidental exposure risks dramatically.

• Complying with safety regulations isn’t optional—it’s expected now more than ever.

These kinds of closures also build trust across all age groups, not just those with kids around. When a lash container feels sturdy and tamper-proof, it signals quality from the jump—even before application begins.

By integrating thoughtful details like child-resistant features into their designs, Topfeel proves that safety can look sleek too.

Steps For Decorating Tubes In Layers

A layered approach to tube decoration brings both flair and function to cosmetic packaging, especially for mascara designs.

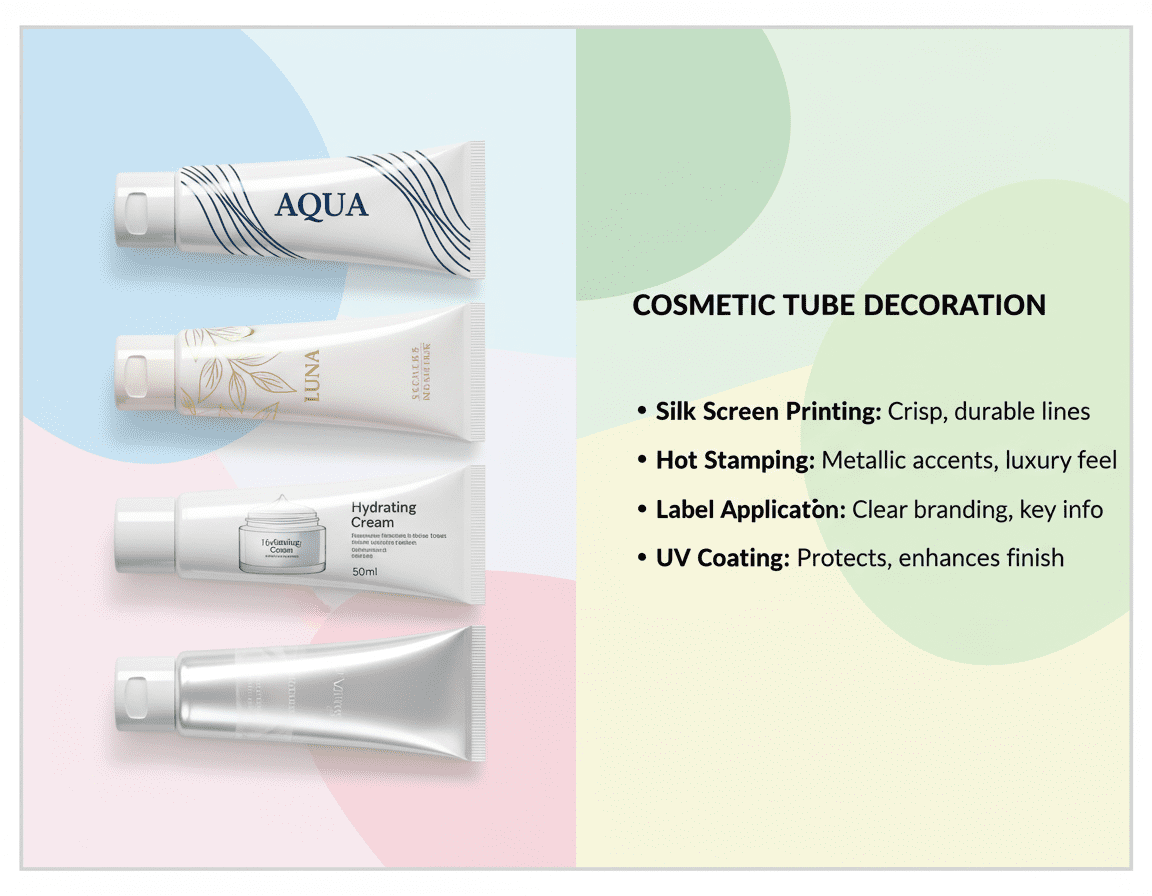

Apply Silk Screen Printing Layer on Empty Mascara Tubes

- Silk screen printing creates crisp lines that hold up over time.

- It’s ideal for bold branding or intricate detailing.

- This method uses mesh screens to transfer ink precisely onto cylindrical surfaces like wand containers.

- Designers can choose from opaque, metallic, or fluorescent inks depending on the target vibe.

- The process works well on both glossy and matte-finished tubes—versatility is its edge.

- For brands experimenting with limited runs, this technique offers fast setup with high visual payoff.

- It’s a go-to when you want color that pops without sacrificing durability.

Add Visual Depth with Hot Stamping Decoration Layer

• Start by crafting a custom die—this tool defines the final look

• Apply pressure and heat using the die to bond metallic foil onto the surface

• Choose between gold, silver, rose gold, or holographic tints based on your style

• Combine hot stamping with embossed textures for more tactile feedback

• This technique adds serious shelf appeal—luxury vibes at first glance

• Works best as an accent over logos or design borders rather than full coverage

• Use sparingly but strategically; it elevates without overwhelming

Secure Branding via Label Application Services

When it comes to getting your product noticed in crowded aisles, clean and professional labeling is non-negotiable. Through label application, brands can showcase identity while delivering key info like volume and ingredients. As noted in Mintel’s 2024 Global Packaging Trends report, “Clear labeling remains one of the top drivers of consumer trust across beauty categories.” That means every sticker counts.

By using adhesive labels tailored to contour around curved tubes, even small-batch mascaras feel premium. Whether it’s automated placement or hand-applied designs, what’s stuck on the outside can say everything about what’s inside.

Seal and Protect with UV Coating Finishes

Glossy? Matte? Somewhere in between? UV finishes give you choices:

– A slick UV coating seals in colors so they don’t fade under sunlight

– Scratches are less likely thanks to added surface toughness

– Want a soft-touch matte finish? That’s doable too—it feels luxe in hand

– The curing process happens fast under UV light so production stays quick

These final touches aren’t just about looks—they’re about keeping that fresh-off-the-line feel long after products hit store shelves. One swipe-resistant layer makes all the difference.

Topfeel integrates all these finishing techniques into its production flow—making sure each packaging piece not only looks sharp but also lasts through real-world use.

3 Ways To Personalize Empty Mascara Tubes

A little flair goes a long way—here are three smart ways to make your mascara packaging pop and stick in people’s minds.

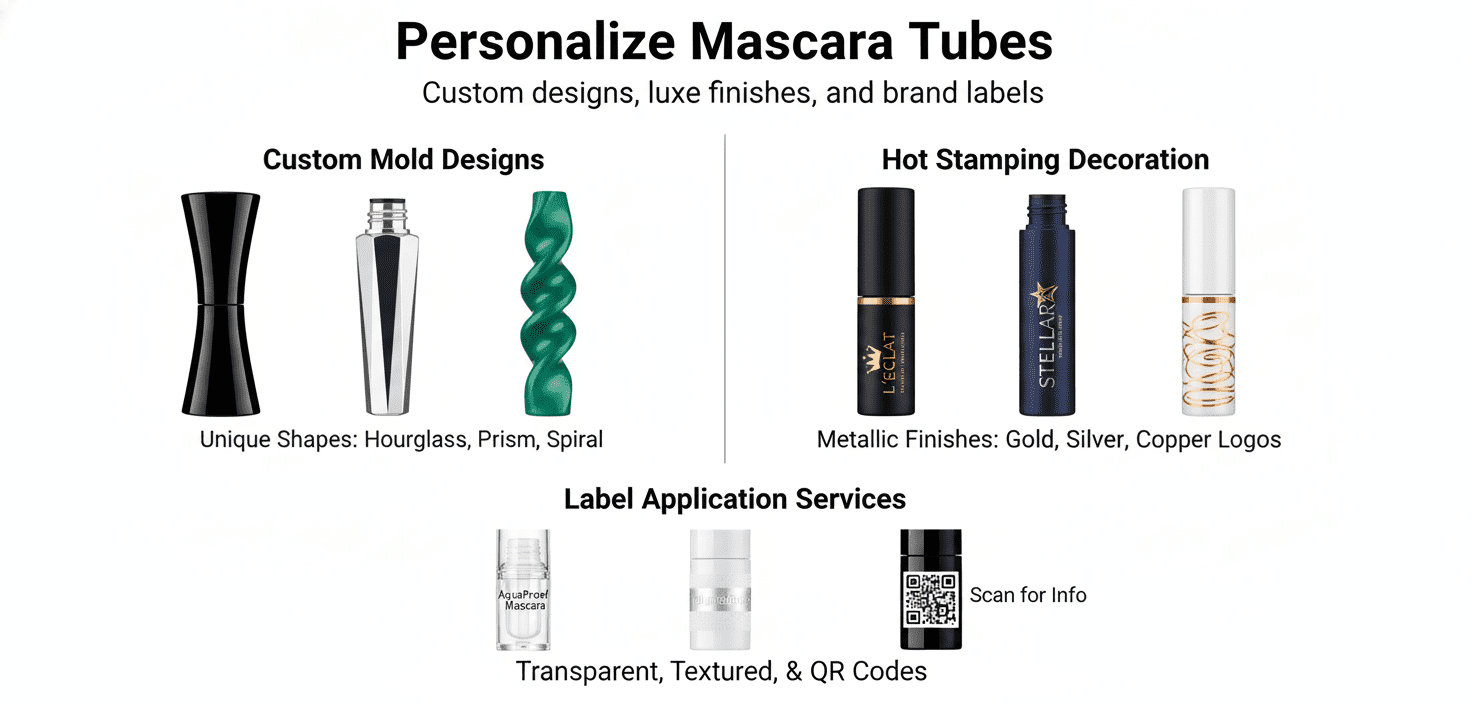

Custom Mold Designs for Unique Mascara Tube Shapes

Want your product to stop traffic? Start with the shape.

- Custom mold options let you ditch the standard cylinder and go bold—think hourglass, prism, or even petal-inspired curves.

- Brands can collaborate directly with manufacturers using injection molding to create eye-catching silhouettes that scream originality.

- A unique form factor doesn’t just look cool—it makes your product easier to spot on shelves crowded with generic tubes.

- Whether it’s angular, ergonomic, or futuristic, a customized mascara tube shape instantly communicates brand personality.

- These designs also help improve grip and application comfort—function meets fashion in the best way possible.

- With an exclusive mold design, customers are more likely to remember—and repurchase—your product.

- And bonus? It’s a great conversation starter when influencers show off their faves online.

Hot Stamping Decoration for Luxe Tube Finishes

Luxury isn’t about shouting; it’s about subtle flexes like metallic finishes that shimmer under light.

▸ Hot stamping uses heat and pressure to press foil onto packaging surfaces—it’s how you get that sleek gold or silver logo that looks like it cost a fortune.

▸ This process works beautifully on both matte and glossy finishes, giving you total creative freedom over texture contrast.

▸ You can choose from holographic films, rose gold foils, or even deep black-on-black effects depending on your vibe.

And here’s the kicker: these luxe details don’t just look good—they build trust fast with premium shoppers who equate visual quality with formula quality.

• Pairing hot-stamped logos with embossed patterns can elevate even minimalist designs into something museum-worthy.

• Many upscale beauty brands swear by this method because it screams polish without being loud.

Even if you’re not going full luxury line, incorporating subtle decoration elements through this method helps signal value—and makes unboxing videos ten times more satisfying.

Label Application Services to Showcase Your Brand on Mascara Tubes

Your label is where storytelling kicks in—and clarity counts big time.

- Professional label application ensures precise alignment and adhesion so your branding never peels or fades mid-use.

- High-end labels often use UV printing techniques paired with waterproof materials that hold up in makeup bags and purses.

- You’ve got options galore:

- Transparent labels for floating text effects

- Textured finishes like soft-touch matte

- Foil accents combined with QR codes for digital engagement

- Want seasonal drops or influencer collabs? Quick-turn custom labels make limited runs totally doable without retooling production lines.

- Beyond logos and names, these stickers carry essential info—from shade numbers to cruelty-free badges—all while keeping things tidy.

- When done right, they turn plain cosmetic containers into mini billboards people actually want to display.

Topfeel offers integrated design-to-print support here—so every piece of packaging tells your story at a glance without missing a beat.

Empty Mascara Tubes: Diy Vs. Professional Kits

A quick look at how you can customize your mascara containers—whether you’re just getting crafty or gearing up for retail.

DIY Tube Decorating Kits

• Grab some craft supplies like stickers, washi tape, and metallic pens to jazz up plain tubes.

• Add sparkle with glitter, tiny charms, or even dried flowers sealed under clear adhesive.

• Use rhinestones and small decals with tweezers for detailed accents.

- Choose a color theme—monochrome, pastel, or neon.

- Clean the surface of the tube before applying any decoration to ensure better adhesion.

✦ Always let glue dry completely before handling your customized piece.

DIY kits are ideal if you’re making gifts, hosting a beauty party, or just want something unique on your vanity. They’re affordable and easy to find at most craft stores, giving you full control over customization without needing bulk orders.

Short bursts of creativity thrive in this space:

- Personalize each tube with initials.

- Mix textures like matte paint and glossy gems.

- Match your makeup bag vibe.

To get started:

- Gather your base materials—empty tubes, brushes, glue.

- Sketch ideas or mood boards.

- Apply decorations layer by layer.

- Let everything cure overnight before use.

Grouped essentials for beginners:

• Tools: brushes, scissors, fine-tip markers

• Embellishments: sequins, lace trim, mini beads

• Adhesives: tacky glue, double-sided tape

The fun is in the freedom—no two designs ever come out alike when you’re working with DIY mascara bodies.

Professional Private Label Kits

• Bulk production starts with sourcing high-quality bulk mascara tubes that match your brand’s aesthetic goals.

• Incorporate custom branding through professional-grade custom labels and tamper-proof seals.

• Work directly with cosmetic manufacturers who offer end-to-end solutions including formulation support and packaging design.

1) Decide on tube shape—slimline? chubby? curved? Each sends a different message to consumers.

2) Align packaging materials with brand values; eco-friendly options are trending hard right now.

☑ Regulatory compliance is non-negotiable if you’re selling across regions like the EU or North America.

Unlike personal projects, these kits aim for consistency and scale—and they come packed with features that make them ready for store shelves straight outta the box.

Each part plays its role:

- The container itself must feel luxe but durable.

- Labels need to be waterproof and print-safe.

- Packaging inserts should tell your story clearly but briefly.

Here’s how suppliers typically break it down:

| Supplier Type | MOQ Units | Customization Options | Lead Time (Days) |

|---|---|---|---|

| Domestic Wholesaler | 500 | Basic label + cap color | 10–14 |

| Overseas Manufacturer | 1000 | Full wrap + embossed logo | 20–30 |

| Boutique Packaging Studio | 250 | Hand-finished touches | 7–10 |

To build a reliable private label line:

Step 1 — Contact several reputable wholesale suppliers for quotes based on volume tiers.

Step 2 — Request samples that include both empty containers and printed mock-ups using their available finishes.

Step 3 — Finalize artwork using professional tools or hire external help for top-tier packaging design work that aligns visually across all SKUs.

In short bursts:

- Think about shelf appeal.

- Don’t skimp on print quality—it matters more than you think.

- Keep regulatory docs handy; audits happen fast in cosmetics land.

From concept to counter display takes effort—but when done right, it’s worth every penny spent on those sleek little tubes bearing your name instead of someone else’s… maybe even Topfeel’s once upon a time!

Faded Colors? Use Uv-Resistant Coatings

UV-resistant coatings don’t just make things shiny—they keep your mascara tubes looking fresh, bold, and on-brand.

How UV Coating Finishes Protect Mascara Tube Colors

• Constant exposure to sunlight can mess with packaging hues. UV rays break down pigments over time.

• A solid UV coating acts like sunglasses for your mascara tubes, shielding them from color degradation.

• These finishes are engineered using advanced polymer science, forming a durable layer that reflects or absorbs harmful light wavelengths.

Too much light = sad, faded colors. With the right finish, though, those vivid designs stay punchy and true-to-form—like they just came off the press yesterday.

Selecting FDA Compliant Materials for UV-Resistant Layers

- Look for materials that meet FDA compliance standards to ensure safety during consumer use.

- Choose suppliers who provide full toxicology reports—no cutting corners on what touches skin or eyes.

- Prioritize traceable sourcing of UV-resistant materials to avoid contamination or regulatory issues.

A recent 2024 report from Mintel noted: “Consumers increasingly expect cosmetic packaging to meet both safety and environmental standards without compromise.” That means your mascara component design needs to check all the right boxes—especially when it comes to material selection.

Ensuring REACH Compliance Regulations in Coating Processes

| Regulation Area | Requirement Type | Typical Substance Concerned | Action Required |

|---|---|---|---|

| SVHC Restrictions | Authorization | Phthalates | Substitute alternatives |

| Safety Data Sheets | Documentation | All chemical coatings | Maintain updated SDS |

| Threshold Limits | Concentration Check | Lead compounds | Regular testing |

| Supply Chain Audits | Verification | Intermediate substances | Annual compliance review |

Following REACH compliance isn’t just about ticking boxes—it’s about avoiding nasty surprises down the line. From raw chemicals to final coating processes, everything must align with EU regulations to ensure both product integrity and environmental protection.

Partner with Sustainable Packaging Vendors for Eco-Friendly UV Finishes

☑️ Find vendors who specialize in eco-friendly coatings with low VOC emissions.

☑️ Ask about their carbon offset programs and how they manage waste during production of UV finishes.

☑️ Confirm if their materials are recyclable or biodegradable—this matters more than ever today.

Short-run packaging might not seem like a big deal—but when you’re pumping out thousands of units of mascara packaging each month, every choice adds up fast. Aligning with vendors who prioritize sustainability reduces your brand’s footprint while still protecting product aesthetics—and yeah, it makes you look good too.

By teaming up with partners who understand both performance and planet-first thinking, you’re setting yourself up for long-term wins in both shelf appeal and customer loyalty—not bad for a simple packaging tweak!

FAQs

Custom molds turn a simple mascara tube into something unforgettable. A curved silhouette, a textured grip, or a sleek, minimalist profile—these details catch the eye and linger in memory. For indie beauty brands and private labels, it’s not just about standing out on the shelf. It’s about telling a story before the wand even touches the lashes.

- Shields printed designs from fading under light exposure

- Keeps colors rich and branding sharp over time

- Adds a subtle gloss or matte finish that feels polished

- Available in eco-conscious formulations for sustainable brands

Absolutely. The shape is just the beginning. Hot stamping adds metallic accents that shimmer under store lights. Silk screen printing creates crisp, tactile logos. Labels bring consistency across your product line. When these elements come together, the packaging becomes part of the product experience.

It’s not just about safety—it’s about peace of mind. In households with curious little ones, a secure closure means one less thing to worry about. These closures meet safety standards without compromising design, making them a smart choice for brands that care about both form and function.

- Lowers cost per unit, freeing up budget for marketing or product development

- Simplifies inventory management with bulk shipping options

- Makes it easier to test different tube styles or finishes without breaking the bank

For small beauty startups, wholesale purchasing is a quiet strategy that builds a louder presence.