Guide to Eco-Friendly Cosmetic Packaging Suppliers

Finding the right cosmetic packaging supplier these days can feel like speed dating in a thunderstorm—too many options, not enough truth. You want someone who talks sustainability but can also handle 500,000 lipstick tubes without blinking. And yeah, you still need that gold foil to pop on your mascara bottle.

Brands are sweating bullets over greenwashing lawsuits and shipping delays while customers expect compostable jars that look like they came from a Paris runway. You’re not just picking packaging—you’re future-proofing your brand’s reputation with every cap and closure. This guide? It’s your flashlight in the fog.

Reading Notes for Choosing the Right Cosmetic Packaging Supplier

→ Define Your Needs First: Clarify your product range—from lipstick tubes to foundation bottles—to identify packaging types and functional requirements.

→ Compare Sustainable Materials: Weigh bamboo packaging against eco-friendly PCR options for environmental impact, cost, and aesthetics.

→ Evaluate Decoration Capabilities: Ensure suppliers offer techniques like hot stamping and UV coating that enhance brand appeal without compromising sustainability.

→ Scrutinize Sustainability Claims: Audit recycled content percentages, biodegradable certifications, and mono-material design capabilities to avoid greenwashing traps.

→ Balance Budget with Green Goals: Explore cost-effective approaches like using reduced plastic or flexible order quantities on aluminum shells to stay within budget.

→ Track Performance Metrics Over Time: Use KPIs and supplier scorecards to monitor delivery timelines, closure integrity, refillable system rollout, and decoration quality.

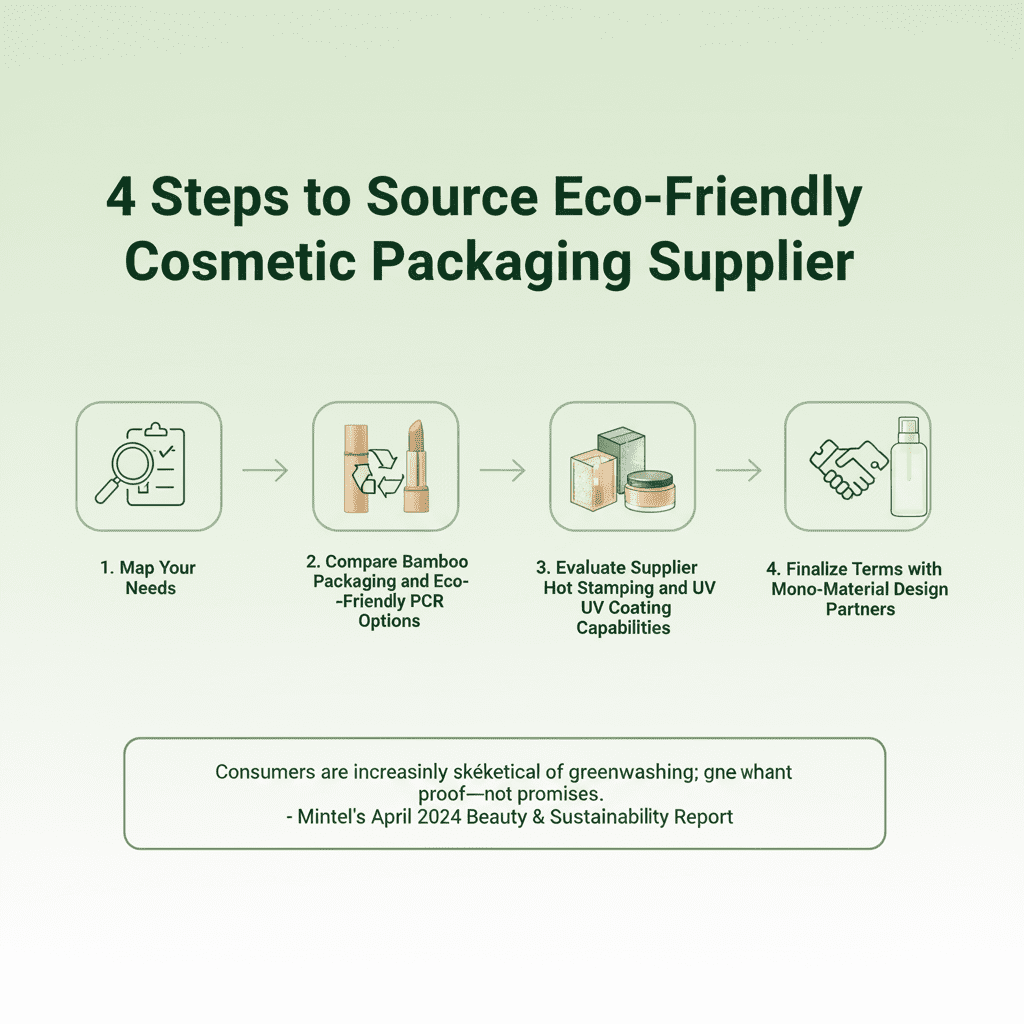

4 Steps to Source Eco-Friendly Cosmetic Packaging Supplier

Finding the right eco-friendly partner for your beauty line isn’t just smart—it’s essential. Here’s how you can break it down and do it right.

Map Your Needs: Lipstick Tubes to Foundation Bottles

You can’t find the right cosmetic packaging partner if you don’t know what you’re actually looking for. Nail down your essentials first:

- Lipstick Tubes: Twist-up, refillable, or magnetic closure?

- Foundation Bottles: Pump, dropper, or airless design?

- Other product types like compacts or jars? Think about volume, function, and finish.

- Consider durability for shipping and shelf life.

- Decide which container types need premium feel vs. minimalist sustainability.

Once you’ve got this sorted out, you’ll be able to talk shop with potential suppliers without fumbling over specs—or worse—ordering packaging that doesn’t fit your vibe.

Compare Bamboo Packaging and Eco-Friendly PCR Options

Choosing between bamboo packaging and eco-friendly PCR isn’t just about looks—it’s about impact. Let’s break this down:

• Bamboo’s all-natural charm works wonders for earthy brands but has limitations in moisture resistance.

• PCR plastic hits the sweet spot between recycled content and functionality—especially when sourced responsibly.

• Want both? Some suppliers now offer hybrid designs using bamboo shells with PCR interiors.

• Keep an eye on certifications like FSC or GRS—they matter more than buzzwords.

According to Mintel’s April 2024 Beauty & Sustainability Report, “Consumers are increasingly skeptical of greenwashing; they want proof—not promises.” So make sure your material choice walks the talk.

Evaluate Supplier Hot Stamping and UV Coating Capabilities

Not every supplier can handle high-quality finishing like precise hot stamping or consistent UV coating, so don’t assume—it pays to ask:

• Do they offer multi-color foil options for hot stamping logos?

• Can they apply gloss/matte UV finishes without warping eco-materials?

• Are their decoration techniques compatible with mono-material designs?

• How do they ensure consistency across large production runs?

If you’re going luxe yet sustainable, these touches bring serious shelf appeal—but only if done right. Ask for samples before committing so you’re not stuck with smudged logos or flaking finishes.

Finalize Terms with Mono-Material Design Partners

This is where deals get real. Once you’ve shortlisted partners skilled in mono-material design, hash out terms that protect both sides—and keep things green:

- Minimum order quantities that align with your scale-up plans.

- Clear timelines on prototyping and production lead times.

- Intellectual property clauses—especially if you’re customizing molds.

- End-of-life recyclability guarantees tied into their supply chain practices.

- Transparent pricing breakdowns by component type and finish level.

It’s also worth checking whether your design partners have worked on circular packaging systems before—that experience can save you months of trial-and-error later.

When sourcing a reliable cosmetic packaging supplier becomes less about guesswork and more about alignment, everything flows better—from product launch to customer loyalty.

Struggling with Costs? Biodegradable Packaging at Lower Prices

Finding a balance between eco-conscious packaging and staying within budget isn’t easy—but it’s far from impossible.

How Eco-Friendly PCR Cuts Costs for Mascara Bottles

Eco-friendly PCR materials aren’t just about saving the planet—they can also help cut down production costs when used smartly in mascara bottles.

- Recycled content reduces raw material expenses, especially when sourced locally.

- Less energy is needed to process PCR, which helps lower manufacturing costs over time.

- Brands that switch to sustainable packaging often qualify for green tax incentives or subsidies.

- Using PCR also trims down shipping weight, since lighter bottles mean cheaper logistics.

By integrating high-percentage PCR into your mascara tube designs, you’re not only dodging some of the high costs associated with virgin plastics but also creating a story consumers want to buy into—literally.

Flexible Order Quantities for Aluminum Shells

Managing your spend on aluminum shells starts with finding suppliers who understand small business realities—and offer flexible MOQs.

• Some packaging solutions providers now cater to indie brands by offering quantities as low as 500 units per size or finish.

• This helps reduce upfront investment without compromising access to premium-feel materials like aluminum.

• A lower minimum order quantity means you can test new designs or seasonal shades without blowing your entire budget on packaging inventory.

Whether you’re experimenting with new product lines or just trying to stay lean, sourcing from a nimble cosmetic packaging supplier makes all the difference when cash flow is tight but quality still matters.

Balancing Budget with Biodegradable Material and Reduced Plastic

Switching to biodegradable options doesn’t have to wreck your bottom line if you’re smart about material selection and design choices:

Step 1: Choose hybrid structures—combine partial biodegradable bases with recycled plastic caps instead of going full compostable right away.

Step 2: Opt for mono-material formats where possible; it simplifies recycling and cuts tooling complexity, which saves money in production runs.

Step 3: Work with suppliers who specialize in custom molds using cost-effective starch-based resins or PLA blends—these are both eco-friendly and wallet-friendly alternatives to traditional plastics.

Step 4: Reduce decorative elements like foil stamping or metallic inks—they drive up costs and hurt recyclability anyway.

By focusing on fewer components and smarter material combos, you can align your brand’s sustainability goals without torching your budget—or sacrificing shelf appeal.

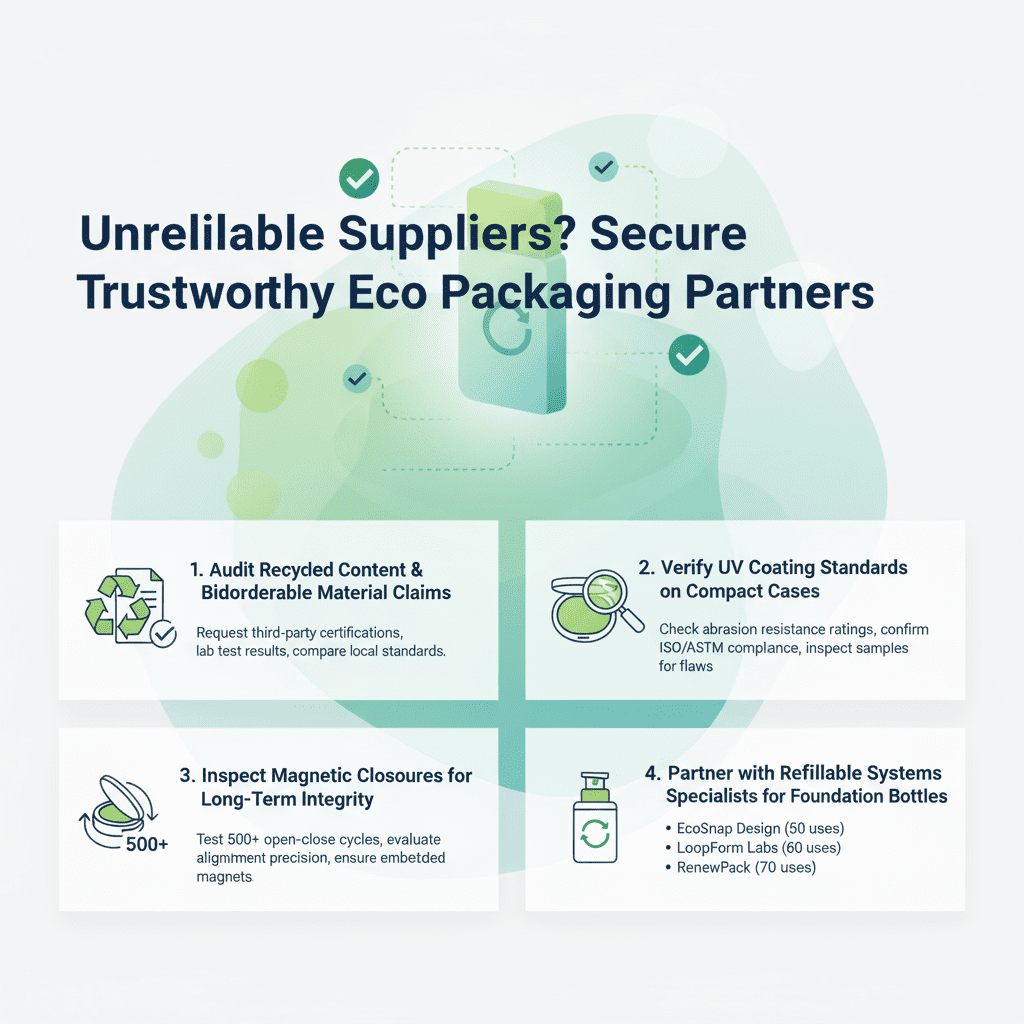

Unreliable Suppliers? Secure Trustworthy Eco Packaging Partners

Finding a reliable eco-conscious packaging source can be a minefield. Here’s how to spot the real ones from the greenwashers.

Audit Recycled Content and Biodegradable Material Claims

You’d be surprised how many suppliers fudge their numbers. To cut through the fluff, make sure you:

- Request third-party certifications for recycled content percentages—don’t just take their word.

- Ask for lab test results proving biodegradable material breakdown times under landfill or composting conditions.

- Compare claimed specs against local environmental standards—regulations vary wildly by region.

Some vendors toss around terms like “eco” and “green” without backing them up. A quick audit of documentation and sourcing trails often reveals if those claims are legit or just marketing spin. If they hesitate to share data? That’s your cue to walk.

Verify UV Coating Standards on Compact Cases

Not all that glitters is durable. When it comes to UV coating on compact cases, dig into these checks:

- Check abrasion resistance ratings—coatings should withstand daily handbag chaos.

- Confirm compliance with ISO or ASTM durability benchmarks for cosmetic-grade finishes.

- Inspect samples under direct light; poor coatings show streaks, bubbles, or yellowing fast.

A supplier might promise shine and protection, but weak coatings will flake off in months, dragging down your brand image fast.

Inspect Magnetic Closures for Long-Term Integrity

Those sleek snaps from magnetic closures aren’t just about looks—they’re functionality lifelines over time:

• Test repeat open-close cycles (500+ times) to simulate consumer use over 6–12 months.

• Evaluate alignment precision; even minor shifts reduce grip strength significantly.

• Ensure magnets are embedded securely within the case body—not glued externally where wear degrades hold.

If you’re skipping this step, your customer might end up with a lid that won’t stay shut after week three—and that’s not cute.

Partner with Refillable Systems Specialists for Foundation Bottles

Sustainability isn’t just about materials—it’s also about design longevity. Working with refillable systems specialists can unlock smarter packaging paths:

| Specialist Name | System Type | Avg Lifespan (Uses) | Compatible Bottle Sizes |

|---|---|---|---|

| EcoSnap Design | Twist-lock Pod | 50 | 15ml / 30ml |

| LoopForm Labs | Magnetic Insert | 60 | Customizable |

| GreenCore Tech | Pump Cartridge | 40 | Standard 30ml |

| RenewPack | Slide Mechanism | 70 | Dual-Chamber |

These pros understand pressure tolerances, hygiene standards, and user behavior patterns inside out—and they’ll help you build foundation formats that actually get reused instead of tossed after one pump dries out. One-time-use is old news; refill-ready is where the smart money’s headed—even Topfeel has started exploring this route quietly behind the scenes.

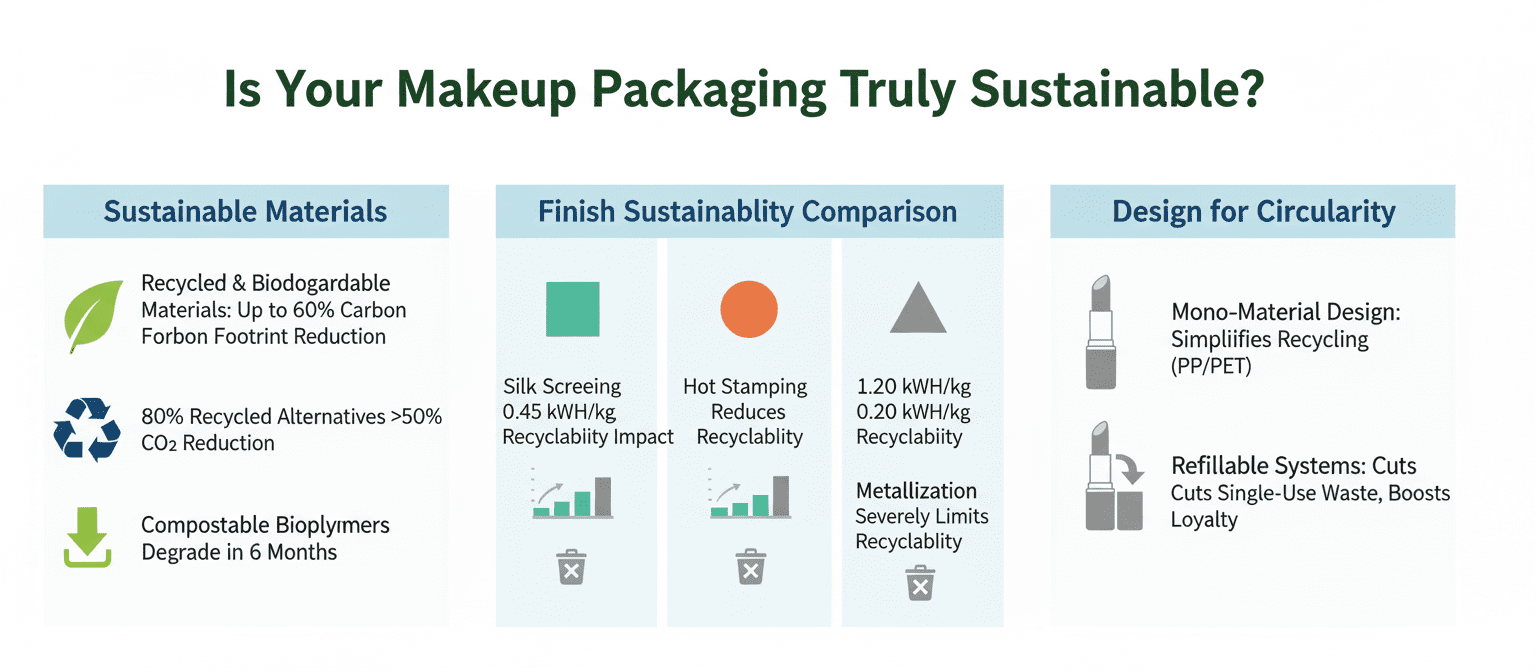

Is Your Makeup Packaging Truly Sustainable?

Sustainability in beauty isn’t just about what’s inside the bottle—it’s also about what wraps around it. Here’s how packaging choices are changing the game.

How Recycled Content and Biodegradable Material Enhance Sustainability

- ♻️ Biodegradable materials like PLA and PHA break down naturally, reducing long-term waste.

- ♻️ Using high levels of recycled content, such as PCR plastics, cuts virgin material use dramatically.

- ♻️ Brands using these materials often lower their carbon footprint by up to 60%.

- Environmental Impact Reduction

- Replacing virgin plastic with 80% recycled alternatives can reduce CO₂ emissions by over 50%.

- Compostable biopolymers degrade within six months under industrial conditions.

- Visual Appeal vs Eco Value

- While biodegradable options may lack gloss, they signal eco-conscious branding that resonates with Gen Z buyers.

-

A few brands have started blending both — for example, lipstick tubes made from recycled aluminum and biodegradable sleeves.

-

The shift toward sustainable cosmetic containers isn’t just ethical—it’s practical too. Many consumers now expect their favorite lipstick or compact to come in a package that won’t outlive them in a landfill.

-

More brands are turning to suppliers who specialize in eco-packaging:

- Some focus solely on post-consumer resin

- Others offer compostable caps or bamboo-based components

- A handful even provide refillable designs made from biodegradable bases

-

Here’s how it works:

Step 1: Choose packaging material with verified recycled content

Step 2: Evaluate biodegradability certifications (e.g., EN13432)

Step 3: Test compatibility with product formula -

Grouped Benefits:

• Environmental – Lower emissions and less landfill impact

• Consumer Trust – Stronger appeal among eco-driven buyers

• Cost Efficiency – Long-term savings via reduced material sourcing -

Combining these strategies makes packaging more than just pretty—it becomes part of the solution.

Comparing Silk Screening, Hot Stamping, and Metallization Finish

- ✴️ Visual finishes can make your lipstick tube pop—but some come at an environmental cost.

- ✴️ Here’s how three top techniques stack up for sustainability:

| Finish Type | Energy Use (kWh/kg) | Recyclability Impact | Aesthetic Quality |

|---|---|---|---|

| Silk Screening | 0.45 | Minimal | Moderate |

| Hot Stamping | 0.75 | Reduces recyclability | High |

| Metallization | 1.20 | Severely limits | Premium |

1️⃣ Silk screening is often favored by eco-conscious brands—it uses less energy and doesn’t interfere much with recycling streams.

2️⃣ Hot stamping may look luxe but involves foil layers that complicate sorting during recycling processes.

3️⃣ Metallization gives that chrome-like sheen but requires vacuum deposition—a high-energy process—and renders plastic nearly unrecyclable unless delaminated first.

Short breakdowns:

• Want minimal impact? Go silk screen.

• Need shine without guilt? Look into water-based metallic inks.

• Avoid metallized finishes if aiming for circularity goals.

Grouped Insight:

• Appearance – All three offer different visual strengths

• Compatibility – Not all finishes work on biodegradable surfaces

• Sustainability Trade-offs – Choose based on balance between design + recyclability

In short, decorative flair shouldn’t mean ecological despair—choose wisely when working with your cosmetic container provider.

Assessing Mono-Material Design and Refillable Systems for Lipstick Tubes

Refillables and mono-material designs aren’t just trendy—they’re smart moves toward real-world sustainability in cosmetics packaging.

Multi-item grouping:

🧩 Mono-Material Perks:

- Simplifies recycling since there’s no need to separate parts

- Often made of PP or PET—both widely accepted by recyclers

- Reduces contamination risk in recycling bins

🔁 Refillable System Advantages:

- Cuts down single-use waste significantly

- Encourages brand loyalty as customers repurchase refills

- Compatible with luxury-grade outer shells for brand distinction

Step-by-step lifecycle of a refillable tube:

→ Buy initial unit made from durable mono-material shell

→ Insert refill bullet once product runs out

→ Repeat use while only replacing inner core

Short hits:

• Lighter tubes = lower shipping emissions

• Easier dismantling = better end-of-life processing

• Consistent design = easier consumer education

More suppliers are offering low-MOQ customizations for these formats, making them accessible even to indie labels hunting for an earth-friendlier route through their preferred cosmetic pack vendor pipeline.

So yeah—if your lipstick still comes in a mixed-plastic throwaway tube… might be time for an upgrade both you and the planet can feel good about.

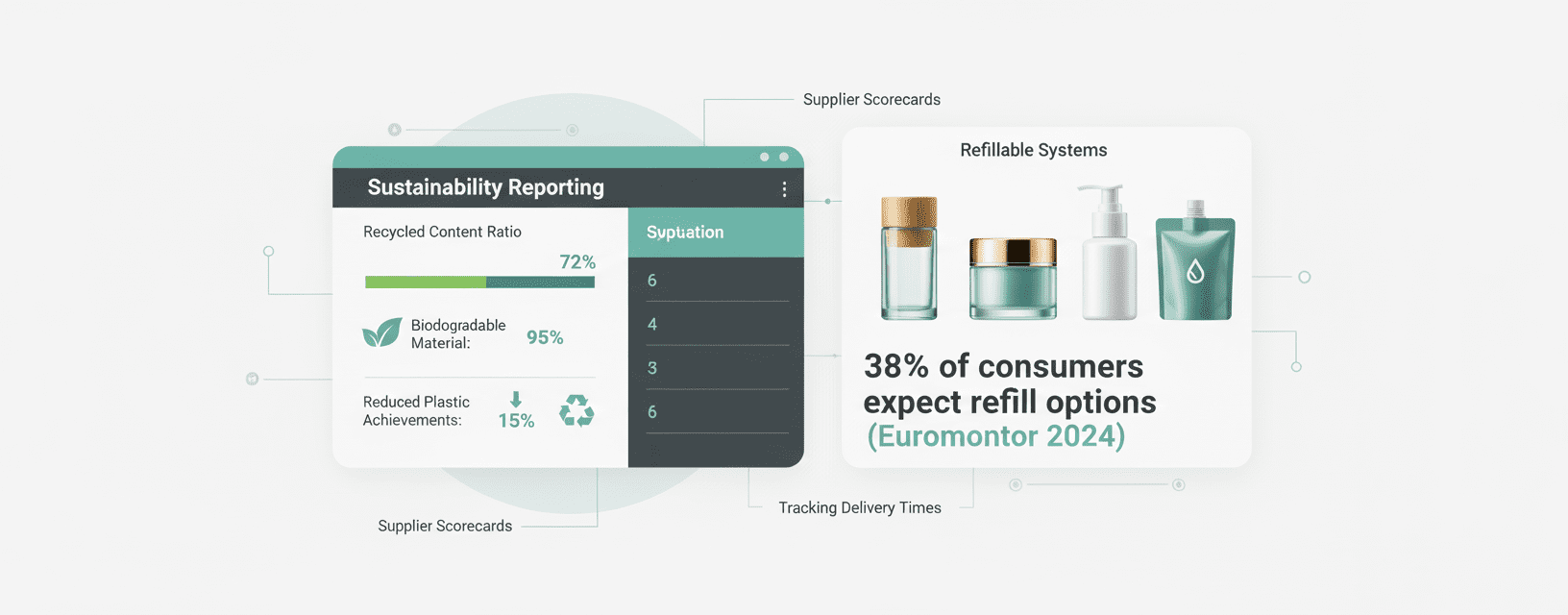

Sustainability Reporting: Track Supplier Impact

Keeping tabs on packaging partners isn’t just about deadlines—it’s about impact. Here’s how to track what really matters across your supply chain.

Establishing KPIs for Recycled Content and Biodegradable Material

- Recycled Content Ratio (% by weight) – Tracks how much post-consumer or industrial material is reused in packaging.

- Biodegradability Timeline – Measures how quickly materials break down under standard composting conditions.

- Material Certification Rate – Percentage of suppliers using third-party certified sustainable materials.

- Annual Reduction in Virgin Plastic Use – Monitors year-over-year drop in new plastic input.

- Packaging Materials Portfolio Mix – Breaks down the share of biodegradable vs. recyclable vs. traditional substrates.

- Environmental Impact Score per SKU – Combines emissions, water use, and waste metrics per product line.

- These KPIs help any cosmetic packaging supplier stay transparent with their eco-goals while nudging partners toward greener practices.

Tracking Delivery Times: From Transparent Clear Bottles to Metallic Gold Cases

• Some shipments glide through customs like butter; others crawl like molasses—especially when you’re juggling everything from transparent clear bottles to flashy metallic gold cases.

- Map out lead times based on packaging type—glass usually lags behind plastics due to fragility protocols.

- Build a rolling average dashboard that tracks delays at the component level—closures, bottle bodies, foil wraps.

- Flag spikes linked to seasonal surges or port congestion so you’re not caught off guard during peak launches.

✳️ Pro tip? Keep your logistics team tight with your design team—last-minute tweaks can blow timelines wide open.

The best cosmetic pack vendors often shine not just by product quality but by how well they handle the clock.

Integrating Supplier Scorecards for Closure Types and Decoration Methods

Step 1: Define criteria based on performance—think defect rates, sustainability ratings, innovation levels in both closure types and surface treatments like hot stamping or silk screening.

Step 2: Assign weights to each factor depending on priority—maybe durability trumps aesthetics this quarter.

Step 3: Collect quarterly data from all vendors tied to specific components like pumps, droppers, or decorative sleeves.

Step 4: Normalize scores across categories using a shared scale so apples aren’t compared with oranges.

Step 5: Rank suppliers into tiers—top-tier gets preferred pricing negotiations; bottom-tier triggers corrective action plans.

By turning subjective impressions into hard numbers, you get a clearer picture of which cosmetic packaging supplier is truly pulling their weight across the board—not just showing up with shiny samples once a year.

Reporting on Refillable Systems and Reduced Plastic Achievements

Refillable formats aren’t just trendy—they’re becoming table stakes for brands serious about sustainability. When tracking success here, it’s all about linking innovation with measurable outcomes. For example:

In its latest Global Packaging Trends report (2024), Euromonitor found that over 38% of consumers now expect refill options as part of a brand’s core offer—not an afterthought. That shift pushes suppliers toward smarter systems that reduce plastic without compromising shelf appeal or function.

So when reporting progress:

Start by quantifying plastic saved per refill cycle versus single-use versions; then tie those numbers back to actual sales volume uptake. Also highlight partnerships where breakthroughs occurred—like switching from rigid PET cartridges to flexible pouches made from low-impact polymers.

It’s not enough anymore for a cosmetic pack provider to say they “support sustainability.” Showcasing real wins in refillable tech separates those who walk the talk from those still stuck in yesterday’s mold.

FAQs

Start by looking at your product line—lipsticks, foundations, mascaras. Each has its own packaging needs. A good supplier won’t just offer options; they’ll ask questions about your brand’s values and help align materials with your message.

- Look for suppliers using post-consumer recycled (PCR) plastics or bamboo

- Ask if their designs support refillable systems or mono-material construction

- Check how far they go with customization—do they offer hot stamping, UV coating, soft-touch finishes?

A thoughtful partner will care as much about aesthetics as ethics.

Not across the board—but it’s changing fast. Foundation bottles are leading the way in refill innovation thanks to pump compatibility and bottle structure. Lipstick tubes are catching up through clever twist-up refills that snap into place without compromising design.

Some brands have even turned this feature into a storytelling element: “Buy once, keep forever.” It’s not just eco—it builds loyalty.