What is Heat Transfer Label?

Ever held a lipstick tube so sleek you didn’t want to toss it when it was empty? That’s no accident. In the beauty biz, packaging is more than a pretty face—it’s your brand’s wingman on the shelf. So, what is heat transfer label tech, and why are cosmetic giants all-in on it? Picture this: instead of stickers that peel or prints that scratch off mid-shelf life, heat transfer labels fuse flawless designs directly onto bottles and jars with pressure and heat—think tattoos for packaging. The result? Bold colors, luxe finishes, and staying power through shipping trucks to steamy bathroom shelves.

Choosing the wrong type can tank a whole product line—off-color logos across 50,000 units isn’t just embarrassing; it’s costly chaos. Material matters. Shape matters. And if you’re scaling fast? Consistency is king. Stick around—we’re breaking down how to pick smart so your next rollout doesn’t miss a beat (or budget).

What Is Heat Transfer Label? Understanding The Basics

Quick intro: Here’s the lowdown on how heat transfer labels work, what they’re made of, and where you’ll spot them every day.

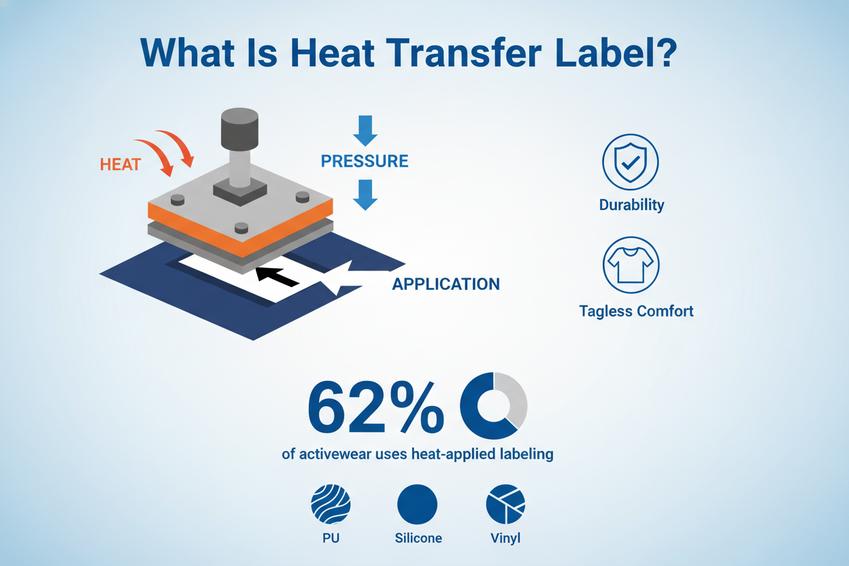

The Science Behind Heat Transfer Labels: How They Work

Getting a heat transfer label to stick isn’t magic—it’s science. Here’s how it all clicks together:

- Step One: A specially designed ink layer is printed onto a carrier film.

- Step Two: During application, heat activates the adhesive activation layer beneath the design.

- Step Three: Pressure is applied, causing thermal energy to trigger the bonding process.

- Step Four: The ink image detaches from the carrier and fuses with the container’s surface through a process called thermal bonding.

This whole dance creates seamless adhesion between printed art and container using controlled temperature and pressure. No peeling, no bubbling—just clean, vivid branding that locks tight through direct substrate adhesion.

Heat Transfer Label Materials: Which Types Are Best?

Let’s break down which materials make heat transfer labeling smooth sailing:

• Acrylic plastic – Top-tier for durability; holds up against moisture and scratches like a champ. • Eco-friendly cardboard – Great for sustainable packaging; pairs well with water-based inks. • Polyester labels – Known for their resilience under high heat during label application. • Label substrates like PET or HDPE – Work flawlessly with cylindrical surfaces due to their flexibility. • Specialized release coatings – Help ensure clean separation between ink layers and film during transfer.

According to Smithers’ Packaging Market Report Q1/2024, “Demand for recyclable substrates compatible with thermal transfer methods is projected to grow by over 11% annually through 2027.” That’s big news for brands going green without sacrificing design quality.

Common Applications of Heat Transfer Labels in Packaging

Heat transfer labels show up more often than you think—especially when you’re grabbing your favorite drink or moisturizer off the shelf.

Short bursts of where they shine:

In beverage aisles: Used on PET bottles for full-wrap designs that resist condensation. In cosmetics: Think sleek jars or tubes where sharp branding matters most. On food containers: Especially those needing microwave-safe or moisture-resistant labeling.

The packaging industry digs these labels because they bond directly to surfaces without extra glue or sleeves. For brands targeting premium appeal, especially within sectors like cosmetic packaging, nothing beats that no-label look fused right into containers via precise application process, heat, and pressure.

You’ll find them on cylindrical bottles just as easily as rectangular palettes—versatility meets style thanks to smart use of tailored inks and advanced adhesives suited for modern-day product branding needs.

Heat Transfer Labels: Why They Matter In Packaging

Heat transfer labels aren’t just about sticking designs on products—they’re key to making items pop on shelves and last through wear and tear.

Enhancing Brand Visibility with Heat Transfer Labels

When asking “what is heat transfer label” and why it matters, you’ll quickly see its power in shaping a product’s look and feel. These labels are more than decoration—they define how your brand shows up.

- A punchy design with high-resolution graphics instantly boosts visual appeal, catching eyes from across the aisle.

- Rich color customization allows brands to stay consistent with their brand identity, even across different packaging types.

- Transparent edges give a no-label look, helping products stand out without distracting clutter—this enhances product differentiation.

- According to NielsenIQ’s 2024 Packaging Impact Study, over 64% of consumers are more likely to pick up products that have clear, bold branding on sleek packaging—proof that shelf presence matters.

- When combined with metallic foils or matte finishes, heat transfer labels create a premium vibe that elevates the entire marketing strategy.

- Whether it’s cosmetics or beverages, standout labeling builds stronger consumer recognition, helping your item become memorable in a crowded market.

So yeah, if you’re still wondering what is heat transfer label tech doing for packaging—it’s turning everyday containers into brand ambassadors.

How Heat Transfer Labels Improve Product Durability

Heat transfer labels don’t just look good—they hold up under pressure. From chemicals to constant handling, durability is where they shine.

• Built-in coatings like soft touch or high-gloss UV add serious scratch resistance, keeping surfaces smooth even after repeated use. • These labels form a tight bond during application, ensuring strong label adhesion that won’t peel off when exposed to water or cleaning agents. • Materials used often include PET or polypropylene blends that boost overall material strength, perfect for rugged environments like gyms or industrial settings. • Electroplated finishes provide extra armor against fading and scuffing, extending the product’s overall lifespan on retail shelves. • Moisture barriers help maintain label integrity in humid spaces—think bathrooms or fridges—offering solid moisture protection without bubbling. • Chemical-resistant inks ensure designs stay crisp when exposed to solvents or oils—a big win for automotive and beauty sectors needing reliable chemical resistance.

So next time someone asks “what is heat transfer label durability really about?”, you’ve got plenty of reasons why these sleek stickers go the distance.

Heat Transfer Vs. Traditional Labels: Which Is Better For Packaging?

Quick breakdown on how heat transfer labels stack up against traditional types when it comes to packaging.

Heat Transfer Labels vs. Adhesive Labels: Pros and Cons

Heat transfer labels and adhesive labels each bring their own vibe to the packaging game, but they don’t play by the same rules.

- Application process: Heat transfer labels are applied using heat and pressure, fusing directly onto surfaces—no peeling corners or sticky residue.

- Durability: These babies hold up against scratches, moisture, and friction way better than your average sticky label.

- Cost-effectiveness: For high-volume production runs, heat transfer can be more economical long-term despite higher setup costs.

- Versatility: Works like a charm on curved surfaces, textured materials, or flexible containers where adhesive labels struggle to stay put.

- Downside? Initial equipment investment is higher compared to just slapping on an adhesive label.

People searching “what is heat transfer label” are often comparing these two because they want something that’ll last—and look good doing it.

Durability and Aesthetics: Heat Transfer Labels vs. Paper Labels

The truth? Paper might be cheap, but it’s no match when you’re aiming for premium packaging with real staying power.

- Durability: Paper tears easily and fades fast—especially around moisture or friction-heavy areas—while heat transfer labels stay crisp and clean.

- Aesthetics: You can’t beat the sleek finish of a heat-transferred design; it looks like it’s part of the product itself.

- “According to Smithers’ 2024 Packaging Outlook,” brands using direct-to-surface technologies like heat transfers saw a 22% increase in perceived quality by consumers.

- Moisture resistance matters big time in food & beverage sectors—paper just can’t hang.

So if you’re still asking “what is heat transfer label” when comparing it with paper options—think less tear-and-wear, more polish-and-wow.

And hey, if you’re considering switching things up? Topfeel’s got tech that makes integrating this labeling method smoother than ever—even on tricky surfaces!

4 Benefits Of Using Heat Transfer Labels For Cosmetic Packaging

A quick peek at why heat transfer labels are shaking up cosmetic packaging with style, sustainability, and serious design power.

Superior Quality Finishes: Silk Screen Printing and Metallization

- Silk screen printing delivers sharp, rich visuals that pop on any surface.

- Metallization adds that luxurious gleam, catching the eye in seconds.

- These finishes elevate the shelf appeal of cosmetics—think high-end without the hefty cost.

- Boosts perceived value instantly with high-end aesthetics

- Works beautifully on both light and dark containers for maximum contrast

• Adds tactile texture for a premium feel consumers love

When you ask “what is heat transfer label” in the context of cosmetics, this is where it shines—literally. It’s not just about sticking on graphics; it’s about making your product unforgettable with quality printing techniques like these.

Eco-Friendly Benefits: Sustainable Material Options for Labels

♻️ Brands are turning to eco-friendly labels, not just to save face—but to save the planet too.

- Made using recyclable labels, reducing landfill waste

- Sourced from sustainable materials, minimizing environmental harm

- Compatible with biodegradable packaging options

More than just looking good, heat transfer labeling supports green initiatives by eliminating excess paper waste and adhesives common in traditional stickers.

According to Mintel’s 2024 Global Packaging Trends Report, over 65% of beauty consumers now prefer brands using “visibly sustainable” packaging elements like green packaging or compostable wraps.

Heat Transfer Labels on Different Shapes: Cylindrical Bottles, Jars, and More

Whether you’re dealing with curved jars or funky-shaped bottles, heat transfer labeling wraps around them like a glove.

• Perfect fit for:

- Cylindrical bottles

- Round or oval jars

- Tapered tubes

• Maintains print clarity even across uneven surfaces

• Eliminates bubbling or peeling often seen with traditional stickers

This makes it ideal for creative cosmetic designs where shape matters as much as color. The ability to apply designs seamlessly across various forms ensures consistent branding across all product lines—no matter how quirky the container gets.

Here’s how different shapes respond to label application:

| Container Type | Label Fit | Surface Finish | Common Use Cases |

|---|---|---|---|

| Cylindrical Bottle | Excellent | Smooth | Serums, Toners |

| Round Jar | Great | Glossy/Matte | Creams, Masks |

| Tapered Tube | Good | Flexible | Lotions, Gels |

| Irregular Shape | Moderate | Customizable | Specialty Products |

Customization at Its Best: Pantone Matched Colors and Metallic Finishes

Customization isn’t just about logos—it’s about vibe control.

- With precise Pantone matching, your brand colors stay consistent across batches.

- Add shimmer or shine using custom metallic finishes for that extra flair.

- Combine both features into one seamless design thanks to advanced heat transfer tech.

Want neon pink lids with gold foil logos? Done deal. Need matte black paired with reflective silver text? No problem either. This is what makes people stop mid-scroll or mid-walk in store aisles—it’s all about those bold choices wrapped in perfect execution through bespoke labels and spot-on color accuracy.

So when someone asks “what is heat transfer label,” tell them it’s your secret weapon for standing out without compromising precision or style.

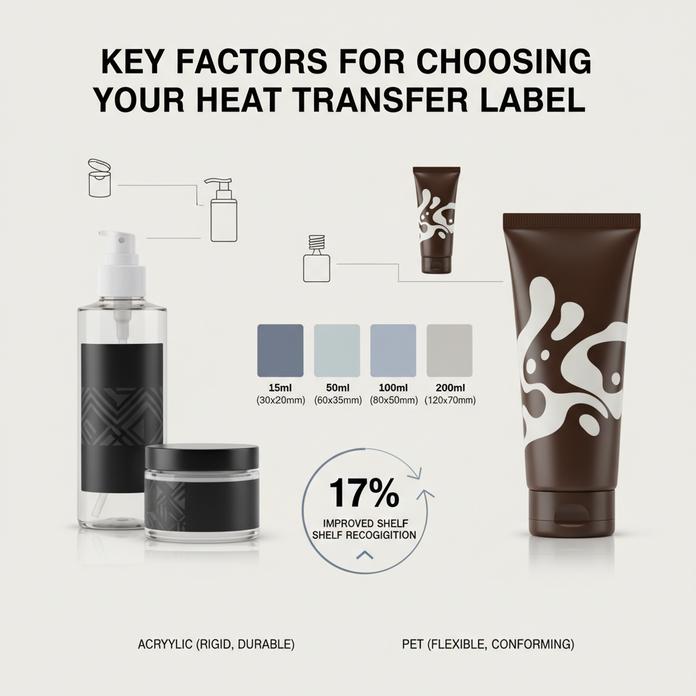

5 Key Factors To Consider When Choosing Heat Transfer Labels

Choosing the right heat transfer label setup? Let’s break down what really matters before you slap that label on.

Material Type: Choosing the Right Substrate for Your Packaging

• Plastic, like PET or HDPE, offers consistent adhesion and is ideal for squeeze tubes and bottles. • Glass needs specialized primers to ensure the transfer sticks properly and lasts. • Metal, such as aluminum, can handle high-temp transfers but requires clean, non-oily surfaces. • Flexible films and coated papers are trickier—they need low-temp labels with strong bonding agents.

Your choice of packaging material isn’t just about looks—it’s about how well your label stays put under pressure.

Color Options: From Custom to Pantone Matched Colors

- Go full custom if you’re chasing a signature shade nobody else has.

- Use Pantone matching for consistency across global print runs.

- CMYK works best when printing photographic images or gradients.

- Want bold branding? Spot colors provide punchy vibrancy with exact tone recall.

- Always test color output on your actual substrate—materials like plastic or metal can subtly shift perception.

Color isn’t just visual—it’s emotional branding in action.

Labeling Method: Hot Foil Stamping vs. UV Coating

Short bursts of detail:

Hot foil stamping = metallic glam + tactile depth; best for luxury items like perfumes or cosmetics. UV coating = slick shine + scratch resistance; great for everyday consumer goods. Both methods enhance shelf appeal but serve different durability needs. Think finish first—glossy vs matte changes how your design pops under light.

Choosing between these two techniques depends on whether you want flash, function—or both.

Closure Types: Impact of Labeling on Pump Dispensers and Spray Nozzles

Grouped insight bullets:

• Pump dispensers often require precise alignment so the graphic doesn’t twist during use. Misaligned labels look sloppy fast.

• For products using a spray nozzle, avoid placing critical artwork too close to the neck area—it might get warped or hidden by caps.

• Closures like flip-tops and twist-locks demand flexibility in label placement since they move or rotate during application.

Always test label fit after assembling closures—function beats form if users can’t open it easily!

Treatment Types: Electroplating vs. Soft Touch Coating for Label Durability

Grouped comparison bullets:

• Electroplating

- Offers superior wear resistance

- Delivers high-gloss metallic effects

- Ideal for containers exposed to moisture or friction

- Works well with rigid plastics and metals

• Soft Touch Coating

- Adds velvety smoothness that feels premium

- Prone to scuffing without topcoat protection

- Perfect for dry-use packaging like skincare jars

- Enhances haptic engagement with minimal glare

Both treatments elevate aesthetics—but only one wins if durability is king.

Application Environment Considerations

Let’s talk real-world usage:

Humidity, heat, cold storage—all these affect how a heat transfer sticks around over time. A bottle stored in a steamy shower needs better adhesive than one sitting on a shelf at room temp. If you’re labeling glass jars filled hot during production? That thermal shock can wreck poor-quality transfers in seconds flat.

Match your transfer type to its future environment—or expect peeling regrets later on.

Graphic Design Compatibility with Heat Transfer Labels

Short notes that matter:

Thin lines may blur under heat pressure—keep vector strokes bold enough. Gradients need testing; some substrates mute fades unpredictably. Avoid placing text near seams or curves unless distortion is acceptable. High-res artwork reduces pixelation risk post-transfer burn-in.

Design smart so what prints matches what you imagined—and survives handling too!

Production Volume & Cost Efficiency Balance

Quick-fire insights:

• Small runs benefit from digital heat transfer systems—no plates needed, quicker turnaround. • Large volumes justify higher setup costs thanks to lower per-unit pricing via screen prep methods. • Factor in waste rates—not all substrates yield perfect transfers every time, especially flexible ones!

Balancing cost efficiency means knowing when volume justifies complexity—and when it doesn’t pay off at all.

Choosing The Right Heat Transfer Label For High-Volume Production

Picking the right heat transfer label for big production runs? Let’s break down what really matters when you’re scaling up.

Managing Large Orders: Factors to Consider for High-Volume Runs

Handling high-volume production isn’t just about printing more labels—it’s about staying sane while doing it. Here’s what you’ll want to watch out for:

• Production capacity – Can your supplier handle thousands per day without breaking a sweat? • Lead time – A long wait can throw off your entire launch schedule. • Cost efficiency – Bulk orders should mean better unit pricing, not surprise fees.

Now combine that with:

Reliable supply chain coordination so materials don’t run dry mid-run. Smart logistics planning to avoid warehouse bottlenecks and delivery delays. Scalable order management systems that don’t crash under pressure.

When asking yourself “what is heat transfer label” and how it fits into this, think of it as the glue between your design vision and real-world scalability. A solid system means fewer headaches—and more profit.

Surface Frosting vs. Vacuum Metallization: Which Works Best for Production?

Choosing between surface frosting and vacuum metallization depends on more than just looks—though both definitely bring style points. Here’s how they stack up when mass production enters the chat:

| Feature | Surface Frosting | Vacuum Metallization |

|---|---|---|

| Visual Appeal | Soft, matte elegance | Sleek, high-shine metallic |

| Durability | Moderate | High |

| Cost Implications | Lower per unit | Higher tooling/setup costs |

| Production Suitability | Easy to scale | Needs specialized equipment |

If you’re producing tens of thousands of units, ask yourself if the added cost of metallization pays off in shelf impact—or if subtle sophistication from frosting does the trick instead.

Both finishes work well with modern heat transfer technology, but depending on your product’s vibe and budget, one may suit your needs better than the other.

Ensuring Consistency: Color Matching and Label Application in High-Volume Runs

Consistency is king when you’re pumping out products at scale using heat transfer labels—especially when consumers expect perfection straight off the shelf.

Step-by-step checklist to keep things tight:

- Calibrate printing equipment regularly to maintain accurate color matching, especially across different batches.

- Use standardized inks and substrates tailored for high-speed runs.

- Maintain strict controls over label positioning (registration) during application.

- Test adhesion under stress conditions—humidity, friction, storage—to ensure long-term durability.

- Implement inline quality checks using digital scanners or AI-based inspection tools.

According to Smithers’ Packaging Report Q1 2024, “Color consistency has become one of the top three indicators influencing consumer trust in FMCG categories.” So yeah—it matters big time.

Good application isn’t just sticking something on straight; it’s about ensuring every single product looks like it belongs on a billboard—even if it’s just sitting on a supermarket shelf.

And remember—when you’re wondering what is heat transfer label tech doing for you here—it’s helping deliver flawless branding at speed without peeling corners or color drift halfway through production week five.

FAQs

1. How does a heat transfer label enhance the feel and look of cosmetic packaging?

It bonds directly onto surfaces like PET plastic, aluminum containers, or glass bottles—no raised edges, no peeling corners—just a smooth sweep of color that feels tailored to the product. Cylindrical bottles or square compacts gleam when paired with metallic gold finish or soft touch coating.

2. Why do production managers favor heat transfer labels for high-volume runs?

- Stays secure even on round jars and oval tubes

- Maintains vibrant Pantone matched colors across thousands of pieces

- Supports extra treatments such as vacuum metallization without losing detail

That combination makes it easier to line up flip top caps or spray nozzles perfectly without slowing output.

3. Which materials respond best during label application with this method?

Acrylic plastic resists warping under machine heat; eco‑friendly cardboard keeps sustainability front-and-center; aluminum containers carry matte black coating with dignity; transparent clear plastic shows off custom color options beautifully in 15ml airless pumps or 50ml cream jars.

4. How do precise colors deepen brand identity using heat transfer printing?

Think uniformity: every 30ml dropper bottle shares the same rich hue as its companion rectangular palette thanks to Pantone matched control charts combined with delicate hot foil stamping highlights—it’s harmony at a glance on any shelf.

5. In what ways is an adhesive label different from heat transfer decoration?

Adhesive designs risk curling away from curved sides like those on a 100ml spray bottle; by contrast, heat transfer stays anchored through moisture and frequent handling while allowing flourishes such as surface frosting or electroplating process for premium impact.

6. Can other decorative methods be layered over a heat transfer design for added drama?

Yes—the tactile joy comes alive when silk screen printing overlays translucent motifs onto pump dispensers finished in metallic gold, while UV coating locks in durability so each swipe against skin feels just as perfect months later.

References

[Smithers’ Packaging Market Report Q1/2024 – https://www.smithers.com/resources/2024/july/sustainability-and-innovation-in-printed-labels]

[NielsenIQ’s 2024 Packaging Impact Study – https://nielseniq.com/global/en/news-center/2024/niq-unveils-comprehensive-2024-consumer-outlook-report-navigating-global-trends-and-insights-for-strategic-growth/]

[Smithers’ 2024 Packaging Outlook – https://www.smithers.com/services/market-reports/printing/the-future-of-thermal-printing-to-2029]

[Mintel’s 2024 Global Packaging Trends Report – https://www.mintel.com/insights/packaging/global-packaging-trends/]

[Smithers’ Packaging Report Q1 2024 – https://www.smithers.com/resources/2024/july/sustainability-and-innovation-in-printed-labels]