Beyond Nostalgia: Why Cosmetic Tins Are a Smart Choice for Modern Brands

Where Durability Meets Perceived Value in Contemporary Packaging Decisions

In cosmetic packaging, materials rarely regain attention without a reason.

When a format returns to relevance, it is usually because it solves problems that newer alternatives struggle with.

While minimalist plastic tubes continue to dominate mass-market shelves, a growing segment of brands is rediscovering the utilitarian elegance of cosmetic tin packaging. Not as a retro statement, and not as a universal solution-but as a deliberate response to durability concerns, sustainability scrutiny, and rising expectations around perceived value.

This renewed interest signals more than a design preference. It reflects how brands are reassessing what packaging is expected to do.

Why Cosmetic Tins Are Reappearing Now – Not by Accident

Several shifts are happening at the same time:

- Increased pressure to move away from disposable plastics

- Higher logistics stress due to longer shipping routes and e-commerce handling

- A stronger link between packaging quality and brand credibility

- Consumer fatigue with packaging that looks sustainable but feels temporary

Within this landscape, cosmetic tins occupy a practical middle ground.

They are not optimized for speed or cost at the lowest tier.

They are optimized for longevity, protection, and brand signaling-qualities that are becoming harder to ignore.

Functional Performance: Where Cosmetic Tin Packaging Still Outperforms

From a manufacturing and usage standpoint, tins continue to perform well where solid and semi-solid cosmetics demand stability rather than flexibility.

They offer:

- Structural rigidity that resists deformation

- Reliable shielding from light exposure

- Consistent performance during transport and repeated use

For balms, pomades, waxes, pressed powders, and solid skincare formats, this combination reduces both formulation risk and post-sale damage.

Real-World Material Performance Comparison

| Packaging Material | Structural Stability | Light Protection | Transport Risk | Long-Term Durability |

|---|---|---|---|---|

| Cosmetic Tins (Tinplate) | High | High | Low | High |

| Plastic Containers | Medium | Low-Medium | Low | Medium |

| Glass Jars | High | Medium | High | Medium |

Manufacturing note: tins are robust, but not immune to poor design choices. Thin gauges, oversized lids, or insufficient curl tolerances can compromise performance-an issue that tends to surface only after mass production begins.

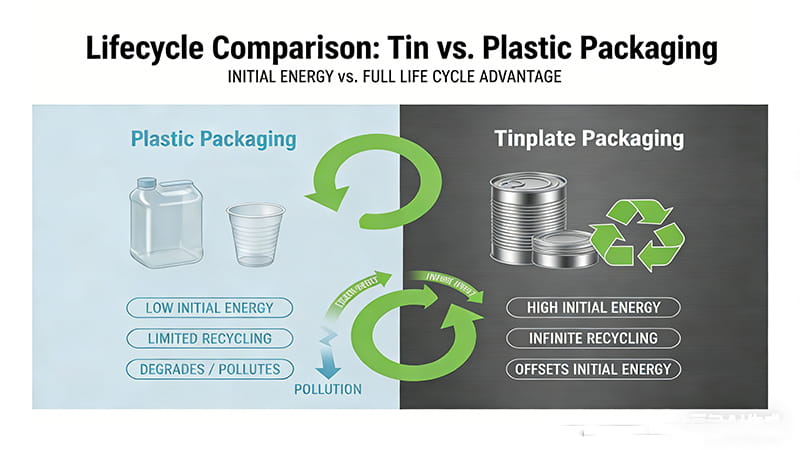

Sustainability Beyond Claims: Lifecycle Reality of Tin Packaging

Sustainability discussions often focus on surface-level indicators.

In practice, what matters is lifecycle performance.

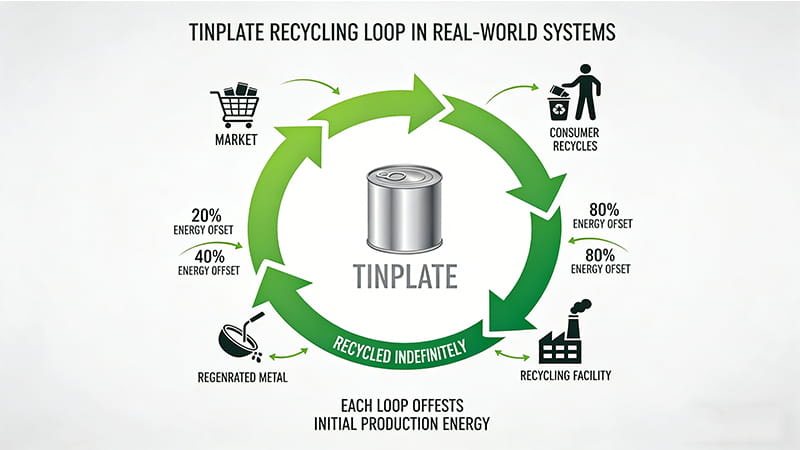

Tinplate production does involve higher initial energy input than some plastics. However, when evaluated over its full lifecycle, embodied energy and recycling benefits often favor metals because they can be recycled repeatedly without loss of quality (see World Steel Association’s lifecycle thinking overview).In real-world terms, this means:

- Steel-based packaging integrates seamlessly into existing recycling systems

- The material can be recycled indefinitely

- Each recycling loop offsets the original production energy over time

Compared to multi-layer plastics-technically recyclable but rarely recycled at scale-cosmetic tin packaging often performs better across its full lifecycle, not just at the disposal stage.

Reuse further strengthens this equation. Tins are frequently kept, refilled, or repurposed, extending their functional life well beyond the original product.

Perceived Value and Consumer Psychology: Why Metal Feels Different

Packaging communicates quality long before a product is used.

In consumer psychology, this is often described through perceived quality cues-subconscious signals that help users judge durability and value without technical knowledge.

Metal tins deliver several of these cues simultaneously:

- Weight suggests substance and longevity

- A cool surface implies material integrity

- The closing “click” reinforces precision and control

These signals are difficult to replicate with plastic, regardless of visual design. From our experience working with cosmetic brands, tins consistently support higher perceived value-especially in premium, gift-oriented, or limited-edition lines.

Design Freedom: Cosmetic Tins as a Branding Surface

Beyond protection and perception, tins function as a stable design platform.

Metal surfaces support decoration techniques that remain visually consistent over time:

- Offset and screen printing

- Embossing and debossing

- Spot UV and textured coatings

- Matte, satin, brushed, or patterned finishes

Decoration Capability by Material

| Feature | Tin Packaging | Plastic | Paperboard |

|---|---|---|---|

| Print Precision | High | Medium | Medium |

| Emboss / Deboss | Yes | Limited | Limited |

| Surface Texture Range | Extensive | Limited | Moderate |

| Long-Term Visual Stability | High | Medium | Low |

For brands that rely on storytelling, seasonal releases, or collectible packaging, tins offer more control-and fewer compromises-than many alternatives.

Practical Trade-Offs: What Brands Should Consider

Cosmetic tins are not without limitations.

Smooth metallic surfaces can show fingerprints or smudges, particularly on high-gloss finishes.

In practice, brands mitigate this through:

- Matte or satin coatings

- Textured or patterned surfaces

- Slightly heavier material gauges

- Clear usage expectations for premium products

When compared with plastic that scratches or glass that breaks, this becomes a manageable trade-off rather than a structural flaw.

Where Cosmetic Tins Fit – and Where They Don’t

Tins are most effective when applied intentionally.

They are well suited for:

- Solid and semi-solid cosmetics

- Products where protection matters more than flexibility

- Brands that emphasize longevity, reuse, or collectability

They are less suitable for mass-market liquids or formats where ultra-lightweight packaging is the primary goal.

Understanding these boundaries is what allows tins to perform as intended.

A Practical Decision Framework for Brands

For brands evaluating cosmetic tin packaging, the key question is not whether tins are popular.

The more useful questions are:

- Does the product form require stronger protection?

- Does the brand story align with material permanence and weight?

- Does the target audience value reuse or collectability?

When these answers align, a tin is no longer just packaging.

It becomes a brand asset-one that supports perception, performance, and long-term value.

References

- Market outlook and growth trends in metal packaging – Smithers.com

- Steel and the circular economy – worldsteel.org/

- Sustainable packaging materials and design trends – packagingeurope.com

- Premium packaging design and decoration insights – thedieline.com