What to Look For in a High-Quality Pressed Powder Case A Guide

When a pressed powder case cracks in transit or fades after a few weeks on the shelf, that’s more than just a packaging flaw—it’s brand sabotage. For bulk buyers juggling tight lead times and even tighter margins, choosing the wrong case can mean customer complaints, damaged reputations, and piles of unsellable inventory.

Brands aren’t just looking for something pretty; they’re hunting for packaging that performs under pressure. You know—hinges that don’t wiggle like loose teeth, closures strong enough to survive handbag chaos, and materials that don’t melt in heat like cheap chocolate. One Topfeel design engineer put it bluntly: “If it doesn’t make it through shipping without scuffing or cracking, we won’t ship it.”

So before you sign off on fifty thousand units of compact heartbreakers, buckle up—we’re about to unpack what really makes a powder case worth its weight in pigment.

Essential Insights into Pressed Powder Case Selection

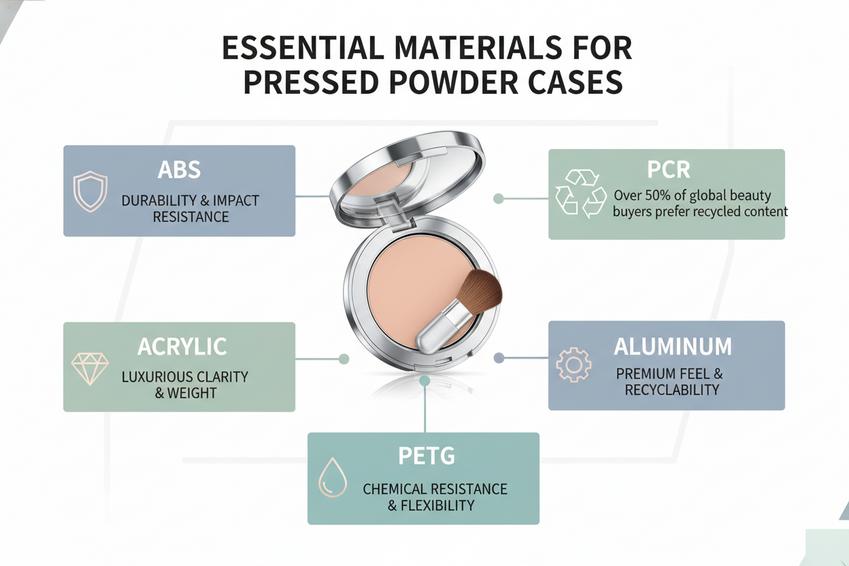

- Material Choices: Consider durability and impact resistance; ABS, Eco-friendly PCR, acrylic, aluminum, and PETG are all viable options for different needs.

- Design Features: Custom color options and silk screen printing can enhance brand identity and aesthetic appeal.

- Closure Mechanisms: Evaluate the safety and convenience of snap closures, magnetic closures, and hinged lids to prevent leakage.

- Convenience of Inserts: Removable trays allow for easy cleaning and customization, catering to various product requirements.

- Care and Maintenance: Utilize gentle cleaning techniques to preserve both metal pan inserts and UV coated finishes for longevity.

Essential Materials for Pressed Powder Cases

Explore how different materials impact the feel, function, and sustainability of your go-to compact.

The Benefits of ABS Plastic in Compact Cases

- Tough enough for daily drops.

- Lightweight but doesn’t feel cheap.

- Ideal for molding detailed designs.

ABS plastic brings serious muscle to a compact case. Its natural toughness makes it perfect for protecting your favorite pressed powders during commutes or travel. Thanks to its high impact resistance, you don’t have to worry about cracks if it slips out of your bag. And since it’s easy to shape, brands can get creative with design without blowing up costs. For everyday users who value durability and sleek looks, this material is a no-brainer.

Why Eco-Friendly PCR is the Future of Packaging

♻️ Brands are shifting toward sustainable materials like PCR plastic not just because it’s trendy—but because customers demand it.

According to NielsenIQ’s Sustainability Report from early 2024, over half of global beauty buyers prefer products packaged with recycled content. That’s where post-consumer recycled (PCR) plastic steps up—cutting down landfill waste while giving packaging a second life. It also supports the circular economy without compromising functionality or shelf appeal. Topfeel has already started integrating PCR into their new lines, proving that green choices can still look luxe.

Comparing Acrylic vs. Aluminum for Durability

| Material | Scratch Resistance | Weight | Visual Appeal | Cost Efficiency |

|---|---|---|---|---|

| Acrylic | Moderate | Light | High | High |

| Aluminum | Excellent | Heavier | Premium | Medium |

Choosing between acrylic and aluminum depends on what matters most—looks or strength? Acrylic offers crystal-clear transparency that enhances color visibility inside a pressed powder case, while aluminum screams luxury and lasts longer under stress. If you’re after something sleek but rugged enough for long-term use, aluminum wins hands down.

PETG: A Lightweight Option for Travel-Sized Products

PETG is kind of like the featherweight champion of cosmetic packaging—it’s light but super tough when it counts.

You’ll often find PETG used for mini compacts or travel-sized pressed powder cases because nobody wants extra weight when they’re packing light. Plus, its shatter resistance keeps things safe even when tossed around inside luggage or handbags. Transparent and flexible without being fragile? That’s why PETG stays winning among on-the-go users who want style without sacrifice. Its portability makes it a smart pick for jet-setters everywhere.

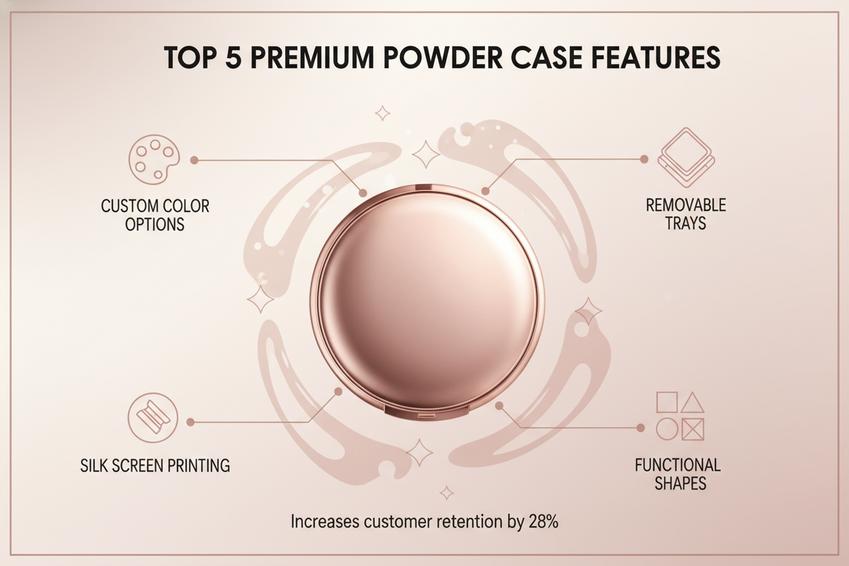

Top 5 Features of Premium Pressed Powder Cases

A great pressed powder case isn’t just about looks—it’s about function, feel, and branding power packed into one sleek compact.

Custom Color Options: Enhance Brand Identity

• Brands that nail their custom colors stand out faster on shelves—think Tiffany blue or Coca-Cola red.

• Matching Pantone shades to corporate palettes helps ensure consistency across every product line.

• Consumers often associate visual cues with trust; color is the first thing they remember.

Visual branding isn’t just fluff—it’s strategy. A well-executed color customization plan allows brands to tell a story without saying a word. With Topfeel, you can match any shade with precision, helping your brand identity pop in crowded markets and on social feeds alike.

The Importance of Silk Screen Printing for Aesthetics

- Clean lines = higher perceived quality.

- Vibrant ink = more eye-catching packaging on display stands.

- Sharp logo application = better brand recall.

Silk screen printing gives your compact case that polished finish people notice even in dim lighting or through store glass displays. This technique ensures your branding elements, like logos and taglines, stay crisp over time—no smudging or fading after a few uses.

According to Future Packaging Insights (2024), “Surface decoration using high-quality silk screen printing increases customer retention by up to 28% in the beauty segment.”

Advantages of Removable Trays in Versatile Design

☑️ Easy pan swaps for seasonal shades

☑️ Supports refillable models—great for eco-conscious buyers

☑️ Makes cleaning hassle-free post-use

Consumers crave flexibility, and nothing says adaptable like removable trays inside a compact case. Whether you’re switching blushes or updating bronzer tones for summer, this feature supports both product longevity and sustainable practices through reduced waste.

Here’s how it breaks down:

| Feature | Benefit | User Type | Environmental Impact |

|---|---|---|---|

| Refillable Compact | Long-term usage | Eco-conscious | High |

| Modular Tray Design | Customization options | Makeup artists | Moderate |

| Snap-in Pan Replacement | Ease of use | Everyday consumer | Low |

Exploring Metallic Finishes for Added Luxury

Gold glints under soft bathroom lights; rose gold reflects warm café vibes; silver stays cool and classic at the office desk—these are the subtle touches that make users fall in love with their compacts.

Luxury isn’t just about price tags—it’s about tactile satisfaction and design harmony. A well-executed metallic finish turns an everyday item into something covetable and gift-worthy. These finishes elevate perception while offering durability against scratches and wear-and-tear from handbags or vanity tops.

Premium brands know this: when users love how it looks, they’re more likely to repurchase—even if it costs more.

Functional Shapes: Round Compact vs. Rectangular Palette

• Round = iconic look + fits palm perfectly

• Rectangular = more space + better brush access

• Both offer distinct advantages depending on user habits

Quick grab-and-go? Opt for a round compact—it’s ergonomic and slips easily into jeans pockets or clutches. Need multiple shades? A rectangular palette offers more real estate without bulkiness.

Choosing between these two shapes affects not only usability but also storage efficiency at home or during travel. The right shape reinforces the overall product form factor while subtly guiding user behavior around makeup routines involving your pressed powder case design choices.

By blending thoughtful geometry with smart features, brands can create compacts that feel tailor-made—even before they’re opened.

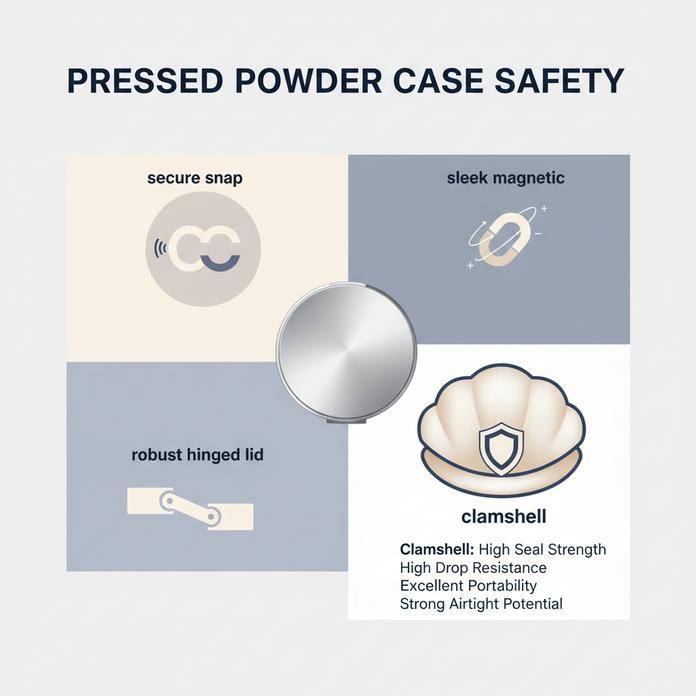

How Closure Mechanisms Affect Pressed Powder Safety

Choosing the right closure can make or break your pressed powder case—literally. Here’s how different designs keep your product intact and mess-free.

Snap Closure vs. Magnetic Closure: Which is Safer?

Different closure mechanisms affect how well your pressed powder case resists drops, spills, and daily wear.

- Snap closures lock tightly with an audible click, giving peace of mind when tossing your compact into a bag.

- Magnetic closures, while sleek and easy to open, can sometimes pop open if jostled too much.

- For long-term travel use, many users prefer snap systems due to their higher resistance to accidental opening.

- However, magnets win in convenience—no fiddling required.

- Both options help maintain product integrity, but snap wins on pure security, especially in high-motion environments.

- The choice often comes down to lifestyle—commuters may favor snap; desk dwellers might lean magnetic.

No matter which you choose, both are way better than screw caps for keeping your pressed pigment safe.

The Role of Hinged Lids in Preventing Spillage

A solid hinged lid isn’t just about style—it’s about keeping the powder where it belongs.

• A tight hinge ensures the lid doesn’t flop open inside your purse

• It creates a semi-sealed environment that helps reduce exposure to dust and moisture

• Hinges also support one-handed operation—a blessing during makeup touch-ups on the go

Ever had a compact explode inside your gym bag? That’s what happens when there’s no proper hinge support. A good hinge forms part of an integrated case design, minimizing both accidental opening and messy leaks. Combine that with a tight fit and you’ve got serious spillage prevention working in your favor.

And let’s not forget hygiene—keeping air out means fewer bacteria creeping into your favorite shade.

Benefits of Clamshell Design for Secure Packaging

The classic clamshell design is more than just pretty packaging—it’s smart engineering for beauty essentials like the trusty pressed powder case.

- It offers full enclosure protection thanks to its overlapping shell halves.

- The double-seal action minimizes air exposure while increasing overall durability.

- Built-in locking tabs add another layer of defense against accidental openings.

- Many clamshells feature an internal gasket or foam insert that enhances their ability to form an almost airtight seal.

- Their flat profile makes them super portable—ideal for slipping into slim bags or pockets without damage risk.

| Feature | Clamshell Design | Standard Lid | Magnetic Case |

|---|---|---|---|

| Seal Strength | High | Medium | Medium |

| Drop Resistance | High | Low | Medium |

| Portability | Excellent | Good | Good |

| Airtight Potential | Strong | Weak | Moderate |

So if you’re looking for something that’s tough yet compact, clamshells are kind of the MVP here when it comes to storing your favorite face fixers like any reliable pressed powder compact format.

How to Clean and Maintain Your Pressed Powder Case

Keeping your pressed powder case clean isn’t just about looks—it’s about hygiene, longevity, and keeping that mirror selfie-worthy. Here’s how to keep it fresh.

Safe Cleaning Techniques for Metal Pan Inserts

When it comes to cleaning the metal pan inserts inside your powder compact, being gentle is key—no harsh scrubbing or random household cleaners. Stick with these tried-and-true methods:

- Use a soft cotton swab dipped in rubbing alcohol to gently wipe around the pan edges.

- For dried-up product residue, use a wooden cuticle stick wrapped in tissue to nudge it free without scratching the metal pan.

- Avoid soaking; instead, spritz lightly with alcohol and wipe dry immediately.

- Disinfect with a diluted vinegar solution (1 part vinegar, 3 parts water) applied with a microfiber cloth.

- Always check if your insert is magnetic or glued—some adhesives break down when wet.

- Don’t forget corners! Bacteria loves hiding where the powder meets the rim.

These tips keep your pressed powder pans spotless without messing up their finish—or worse, contaminating your makeup.

Maintaining the Finish: Tips for Cleaning UV Coated Cases

The outer shell of your pressed powder case, especially one with a sleek UV coating, deserves just as much love as what’s inside. Here’s how to keep that shiny surface looking boss without accidentally dulling it:

• Start by wiping down the exterior gently using a lint-free cloth dampened with warm water—nothing fancy needed here.

• If fingerprints or smudges linger, mix one drop of mild dish soap into half a cup of water and lightly dab it on using circular motions.

• Never use alcohol or acetone—they’ll strip that glossy case finish faster than you can say “oops.”

A few extra pro tips? Store away from direct sunlight to prevent yellowing over time; stash it upright so abrasive surfaces don’t scuff up that gorgeous top layer; and give it a quick once-over weekly if you toss it into bags often.

Preserving the luster means treating your UV coated case like jewelry—handle with care but clean consistently.

FAQs

1. Which materials create the best balance between strength and visual appeal?

Pressed powder cases often blend function with charm:

- ABS plastic keeps products protected through daily handling.

- Aluminum catches light beautifully, favored by luxury cosmetics.

- Acrylic and PETG bring clarity and portability for travel-sized products.

Each material speaks a different style — sturdy, elegant, or feather-light — depending on brand priorities.

2. How does eco-friendly PCR improve large-scale cosmetic packaging?

Eco-conscious brands find eco-friendly PCR (post-consumer recycled plastic) cuts waste while staying compatible with professional makeup standards. It fits naturally in run-after-run bulk orders where sustainability becomes part of product storytelling instead of just logistics.

3. What closure choices make a pressed powder case more secure during shipping?

Security starts in small mechanical details:

① A firm snap closure resists accidental openings;

② Clean magnetic attraction ensures steady use;

③ The protective embrace of a clamshell design shelters fragile powders shipped across continents.

Each closure type transforms reliability into confidence every time the compact clicks shut.

4. How do case shapes influence market attention and usage style?

Shape variety changes emotional appeal as much as practicality:

| Shape | Appeal | Ideal Market |

|---|---|---|

| Round compact | Classic handheld feel | Luxury cosmetics / Single shades |

| Rectangular palette | Multi-color coordination | Professional makeup kits |

| Square case / Oval container / Custom shape | Distinct shelf identity | Brand differentiation |

Every curve or corner alters how users connect to their beauty routine.

5. What decorative treatments strengthen branding potential for pressed powder cases?

Silk screen printing brings crisp icons alive under fingertips; hot stamping adds metallic glow suited to premium lines; UV coating guards each hue from fading during storage. Many designers pair them—visual art meeting tactile satisfaction—to mirror each label’s personality right on the surface.

6. Why are refillable or removable trays appealing for long-term cost control?

Inside structure tells another story: a simple switch between metal pan or refillable insert lowers ongoing material spend while supporting sustainable culture among mass market and eco-conscious brands. These hidden efficiencies allow continuous style updates without replacing an entire compact shell—smart elegance inside out.

References

- Sustainability/ESG – NIQ

- ABS vs PETG Which One is Right for Your Cosmetic Packaging

- Aluminum Packaging vs. Plastic Packaging in Beauty: Which is Better?

- PETG Plastic: Properties, Uses & Advantages 2025 Update

- What are the advantages of silk screen printing for cosmetic container – APG Packaging

- The Future of Packaging: Trends to Watch in 2024

- Everything You Need To Know About PETG Plastic Film – PolymerFilms