The Ultimate Guide to Working with a Packaging Products Factory in 2026

In 2026, your packaging products factory isn’t just pumping out tubes and compacts—it’s a make-or-break extension of your brand. With eco laws tightening and beauty shelves more crowded than a Black Friday sale at Sephora, choosing the right partner can either elevate your product or send it straight to clearance bins. Factories now do more than mold plastic—they shape perception.

The beauty biz has officially outgrown plain jars and basic boxes. It’s all about refillable clicks, velvet-touch finishes, hot-stamped logos that scream “premium”—and getting it all done yesterday. This guide breaks down how to find factories that speak your design language, meet real-world deadlines, and don’t ghost you when you ask for recycled PET with pearl shimmer accents.

Essential Insights for Choosing the Right Packaging Products Factory

- Factory Specialization: Focus on factories that excel in specific packaging types, such as Compact Cases or Lipstick Tubes, to enhance quality and innovation.

- Material Consideration: Evaluate material options like Acrylic Plastic, Glass Bottles, and Aluminum Shells to ensure they align with your brand’s vision.

- Decoration Techniques: Look for factories that offer advanced decoration techniques like Hot Stamping, Silk Screen Printing, and UV Coating to improve packaging aesthetics.

- Production Capacity: Assess the factory’s ability to handle your required production volume across varying sizes, from 5 ml to 100 ml.

- Delivery Reliability: Prioritize partners known for consistent delivery schedules to ensure timely market entry.

- Sustainable Practices: Demand eco-friendly materials such as Recycled PET and Eco-Friendly Paperboard to cater to environmentally conscious consumers.

- Customization Features: Seek factories that provide options for custom color blends and effective surface finishes, helping to elevate your brand identity.

How to Choose the Right Packaging Products Factory

Picking the right packaging products factory can make or break your product’s vibe. Let’s walk through what really matters when you’re sizing up your options.

Evaluating Factory Specializations: Compact Cases vs. Lipstick Tubes

Not all factories are built the same—some shine with compact cases, while others ace it with lipstick tubes. Here’s how to spot the difference:

- ✔ Factories focused on compact cases often invest in precision molds for hinge alignment and mirror placement.

- ✔ Those specializing in lipstick tubes usually have better tech for twist mechanics and airtight seals.

- ✔ A solid production focus means fewer defects, faster turnarounds, and more innovation in that category.

Ask them what percentage of their output is dedicated to each category. If it’s split evenly, they might not be a master of either. You want a shop that knows your item inside out—literally.

Comparing Material Options for Your Product Line

The material you pick speaks volumes about your brand. Here’s a quick breakdown of key material options:

- Acrylic Plastic – Affordable, sleek, but scratches easily.

- Glass Bottles – Premium feel, recyclable, but heavier.

- Aluminum Shells – Durable and luxe-looking, but costlier.

You’ve got to weigh aesthetics against practicality here. A minimalist skincare line might lean into glass; a bold makeup brand could go all-in on glossy acrylics. Think about how each material aligns with your values—like sustainability, cost-efficiency, and durability—and how it vibes with your audience.

Key Considerations for Quality Decoration Techniques

Your packaging’s finish says as much as its function. The right decoration techniques can elevate even basic designs:

• Hot Stamping → Adds metallic shine; great for logos

• Silk Screen Printing → Crisp detail on curved surfaces

• UV Coating → Protects print while adding gloss or matte texture

Here’s what Euromonitor noted in their 2024 Q1 Beauty Packaging Report: “Consumers increasingly associate premium finishes like UV coating with higher product quality.” That means these touches aren’t just pretty—they influence buying decisions too.

Make sure the factory has real chops in these areas—not just offering them on paper but delivering consistent results batch after batch.

Assessing Production Capacity: Small vs. Large Runs

Does your chosen packaging products factory handle nimble startup orders or only mega-corporate volumes? It matters big time:

- MOQ (Minimum Order Quantity): Some places won’t blink under 10K units; others are cool with 500.

- Lead Times: Small-run flexibility often comes at the cost of slower delivery if capacity is tight.

- Scalability: Can they grow with you? Today it’s 5 ml jars—tomorrow maybe full-size kits up to 100 ml bottles?

If you’re launching multiple SKUs across different sizes or materials, make sure their setup supports both small pilot runs and scaling up later without switching manufacturers midstream.

Choosing smart now saves major headaches down the road—and keeps your launch timeline tight when it counts most.

5 Key Features to Demand From Your Packaging Partner

Choosing the right packaging products factory isn’t just about price—it’s about performance, consistency, and brand synergy. Here’s what really counts.

Reliability in Delivery Timelines: Why It Matters

- Missed deadlines can wreck product launches.

- Unreliable logistics creates bottlenecks in your supply chain management.

- On-time delivery builds trust and keeps your shelves stocked.

- Late shipments disrupt production schedules.

- Delays ripple through retail partners and e-commerce timelines.

- Reliable lead times give you room to plan marketing pushes confidently.

♦ Brands that hit their launch windows consistently? They’ve got a partner with tight control over order fulfillment, not just flashy packaging samples.

A good packaging products factory knows that sticking to promised deadlines is as important as the design itself. If they can’t keep up with your pace, you’re better off elsewhere.

Advanced Closure Types: Screw-on Caps vs. Pump Dispensers

Screw-on or pump? It’s not just preference—it’s purpose-driven design based on product texture, viscosity, and user behavior.

-

Screw-on caps:

- Best for travel-friendly formats

- Lower cost per unit

- Secure product sealing

-

Pump dispensers:

- Ideal for lotions, soaps, serums

- Enhance user experience

- Built-in dispensing solutions

Grouped by category:

| Closure Type | Functionality | Ideal Use Cases | Cost Range |

|---|---|---|---|

| Screw-on Caps | Manual seal | Cream jars, oils | Low |

| Pump Dispensers | Measured dispensing | Liquid skincare | Medium |

| Flip-top Caps | Quick access | Shampoos | Low-Medium |

| Airless Pumps | Oxygen-free storage | Serums, actives | High |

Your ideal closure depends on how customers interact with the product—and whether your chosen packaging products factory can deliver consistent quality across these varying components.

Importance of Sustainable Materials: Eco-Friendly Paperboard vs. Recycled PET

♻️ Greenwashing is out—real sustainability is in. The right material speaks volumes to eco-conscious buyers without saying a word.

• Eco-friendly paperboard: • Renewable source • Biodegradable over time • Great for dry goods or secondary packaging

• Recycled PET: • Diverts plastic from landfills • Maintains durability and clarity • Ideal for liquids or transparent needs

The best packaging products factory offers both options—and helps you weigh carbon impact versus utility. Choosing between biodegradable plastics or recycled materials isn’t just about ticking boxes anymore; it’s about aligning with real-world consumer values rooted in the evolving demands of the circular economy and minimizing long-term environmental impact.

Custom Color Blends: Elevating Your Brand Identity

Color isn’t decoration—it’s communication. A custom blend turns ordinary into unmistakable branding power.

Short bursts of insight:

• Want instant shelf recognition? Use bold Pantone-matched tones.

• Need premium vibes? Go deep jewel tones or metallic accents.

• Going minimalist? Soft neutrals speak quiet luxury loud and clear.

• Seasonal launches? Limited-edition colorways make them pop.

• Consistency matters—your shade should match across all SKUs globally.

A skilled packaging products factory doesn’t just mix paint—they understand how color affects perception at every touchpoint of your brand identity. Whether it’s for visual appeal or sharp brand recognition, investing in thoughtful color matching pays off big-time at point-of-sale displays and online thumbnails alike.

Effective Surface Finishes for Packaging Appeal

Surface finish transforms tactile interaction into emotional connection—and it starts before someone even opens the box.

Grouped by sensory appeal:

-

Visual Impact:

- Glossy Finish = Sleek & modern shine

- Matte Finish = Understated elegance

- Metallic Foils = Luxury cues

-

Tactile Experience:

- Soft-touch Coating = Velvet feel that screams premium

- Embossing = Elevated logos that invite touch

- Debossing = Subtle depth adding intrigue

When evaluating a potential partner, check if their finish options match your vision—not all factories can execute advanced techniques like soft-touch coatings without sacrificing durability or print clarity. The right surface finish influences buying decisions more than most people realize—and any high-performing packaging products factory should be fluent in this silent language of texture and light.

The Importance of Customization in Packaging Products

Customization isn’t just flair—it’s function, strategy, and shelf power all rolled into one. From volume to visuals, every tweak makes your packaging products factory output smarter.

Tailoring Capacity Options: Balancing Volume with Product Needs

- 5 ml to under-30 ml: Ideal for serums, trial kits, or travel-sized cosmetics—great for agile brands testing new waters.

- 30–60 ml: Common sweet spot for daily-use skincare or mid-range haircare items where balance matters.

- Above 60 ml up to 100 ml: Works well for lotions or cleansing solutions; bulk-friendly without being bulky.

Now consider this: if your packaging products factory doesn’t offer flexible sizing options, you’re not optimizing production flow or inventory management. Matching the right bottle size to the product helps reduce waste and cost while improving consumer experience. A packaging size mismatch can mean overfill issues or underwhelming presentation—neither is good for business.

Unique Decoration Techniques: Hot Stamping vs. UV Coating

Here’s how two standout techniques stack up:

| Technique | Visual Impact | Durability | Cost Efficiency |

|---|---|---|---|

| Hot Stamping | High-shine luxury | Very durable | Moderate |

| UV Coating | Glossy & modern | Scratch-resistant | Lower |

According to Mintel’s Beauty Packaging Report Q2/2024, “Consumers increasingly associate high-gloss finishes with premium quality,” which makes both these techniques prime choices for brands aiming at upscale markets.

So whether you’re going bold with metallic accents via hot stamping, or keeping it sleek with rich gloss from UV coating, both elevate your brand’s visual game significantly inside any retail aisle.

Why Custom Design Matters: Creating Eye-Catching Mascara Bottles

Let’s be real—mascara is everywhere. So how do you make yours pop?

• Start with shape: Curved tubes? Angular silhouettes? Unique forms instantly grab attention.

• Then color it right: Neon pops? Matte black chic? Color triggers emotion faster than text ever could.

• Add tactile details like embossing or soft-touch finish—that subtle touch can drive major impulse buys.

Your go-to packaging products factory should help you nail that distinctive look while staying true to your brand vibe. Because when it comes to mascara bottles, boring equals invisible.

How Size Choices Affect Production and Inventory Strategy

Short runs? Bulk orders? Either way, capacity planning affects everything:

- Smaller units mean more frequent reorders but easier storage.

- Larger units reduce packaging waste but demand more shelf space.

- Mid-range volumes offer balance but require tight forecasting control.

Smart brands work closely with their packaging products factory partners to align fill size with actual usage data—not just guesswork—to optimize both stock turnover and customer satisfaction levels.

Decorating Smartly Without Blowing the Budget

There are ways to dazzle without draining funds:

▪ Combine low-cost base materials with premium surface finishes like matte varnish + foil accents.

▪ Use digital printing instead of traditional plates if you’re running limited editions.

▪ Opt for hybrid designs—say part-labels plus partial direct print—for flexibility and savings.

A clever blend of decoration methods lets even indie brands get that high-end look without breaking the bank—or slowing down production lines at their chosen packaging products factory.

Customization as a Brand Differentiator in Crowded Markets

Fast facts:

• Over 70% of consumers say packaging influences purchase decisions on first-time buys.* • Brands using unique shapes/colors report higher recall rates.*

(*Data sourced from Euromonitor Beauty Consumer Trends Report, April 2024)

So yeah—it’s not fluff. A well-designed mascara tube or skincare bottle doesn’t just hold product; it holds potential influence over buying behavior too.

When your design screams “you,” customers remember—and return—even amidst a hundred similar SKUs on shelves near them.

Coordinating Design With Manufacturing Efficiency

To keep things running smooth between design labs and filling lines:

Step One: Finalize artwork early so tooling doesn’t delay mass production timelines.

Step Two: Align decorative elements like labels or stamps with machine capabilities at your selected packaging products factory—not all factories handle all finishes well!

Step Three: Test-fill samples before full runs begin; this avoids last-minute surprises like ink smearing during capping stages.

Efficiency meets creativity when there’s tight coordination between design ambition and manufacturing reality—and that only happens when you pick a partner who knows both sides inside out.

Preparing For Your First Order With a Packaging Factory

Starting your first order with a packaging products factory? Here’s what you absolutely need to know before anything hits the production line.

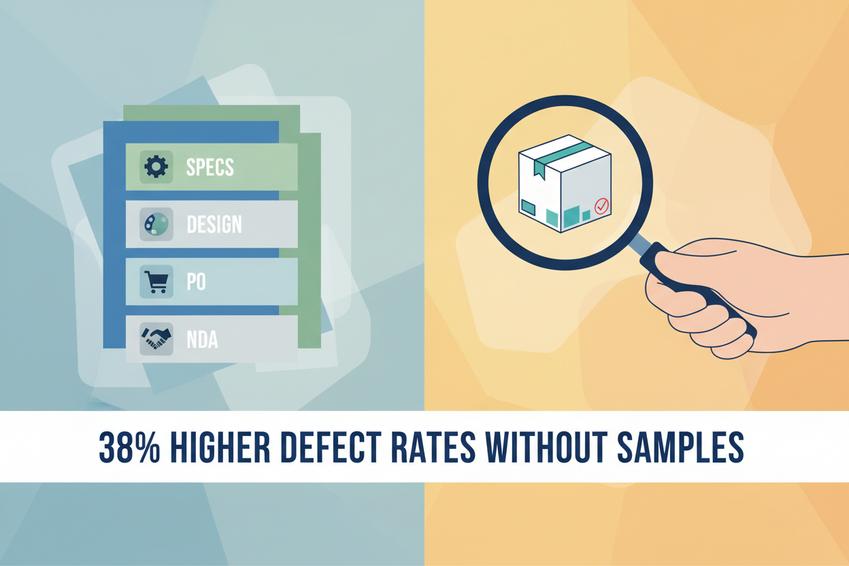

Essential Documentation: What You Need to Proceed

Before any packaging products factory starts churning out boxes or labels, you’ve got to come prepared with some key paperwork and details:

- Specifications — Include precise dimensions, materials, finishes, and tolerances. This helps avoid confusion and costly errors.

- Design Files — Vector formats like AI or PDF are ideal for printing clarity and layout accuracy.

- Purchase Order (PO) — Clearly outline quantities, SKUs, pricing agreements, and delivery deadlines.

- Material Certifications — If you’re using eco-friendly or food-grade materials, these are non-negotiable.

- Non-Disclosure Agreement (NDA) — Protects your designs and product info from being shared elsewhere.

- Shipping Instructions — Labeling requirements, pallet specs, destination addresses—don’t leave it vague.

- Payment Terms — Be upfront about deposits, credit periods, or milestone payments.

Without these in place, even the best packaging factory can’t move forward smoothly. It’s not just about placing an order—it’s about setting up success from day one.

Understanding Production Samples: Ensuring Quality Before Mass Production

You wouldn’t buy a car without test-driving it—same goes for working with a packaging products factory. Getting the right sample is everything.

Start by requesting a pre-production sample, which reflects how your final product will look and feel using actual materials. This isn’t just some mockup; it’s the real deal minus the full volume.

Then comes the inspection phase:

• Use this time to do thorough material verification, checking if textures match expectations or if colors align with brand guidelines.

• Run basic durability tests—does that folding carton hold weight? Does ink smudge under pressure?

If all checks out during this informal round of internal testing, move on to formalizing your approval through an official sign-off process—aka the green light for mass production.

According to Smithers’ 2024 Global Packaging Report, “Brands that skip physical sampling face up to 38% higher defect rates in initial runs.” So yeah—it pays to slow down before scaling up.

Getting your sample right isn’t just quality control—it’s peace of mind when thousands of units start rolling off that line at your chosen packaging products factory.

FAQs

How do I select the right factory for my cosmetic collection?

A good choice feels like finding a kindred spirit—one who understands your brand’s personality.

- Look for skill in PackagingTypes you actually need: Compact Cases, Lipstick Tubes, Mascara Bottles.

- Match their material craft to your vision: Acrylic Plastic for modern clarity, Glass Bottles for timeless weight, Aluminum Shells for sleek strength.

- Test their artistry with Hot Stamping or UV Coating so every surface tells your story.

Which surface finishes give packaging an emotional pull in the shopper’s hand?

Glossy Finish whispers glamour; Soft-Touch Coating makes fingers linger; Matte Finish speaks with quiet confidence. The finish is skin-to-skin communication—instant chemistry at first touch.

Why does dependable delivery feel like a lifeline in cosmetics?

Unreliable timelines can strangle momentum:

- Marketing loses rhythm when launch dates stumble.

- Retail shelves wait—empty.

- Loyal buyers slip away to competitors while stock lags.

Trust isn’t just built—it’s shipped on time.

What closure designs keep liquid foundation both safe and stylish?

Every closure tells its own tale: Pump Dispensers offer control and cleanliness; Screw-on Caps place security above all else; Magnetic Closures add that small theatrical moment each morning before makeup begins.

Can colors alone deepen the bond between product and brand identity?

Yes—and it happens almost subconsciously: Pantone Matched Colors ensure harmony across Eyeliner Pens, Foundation Bottles, Lipstick Tubes; Custom Color Blends open doors to moods unique as fingerprints; Pearlized Pigments bathe surfaces in subtle light plays shoppers can’t stop turning in their hands.

| Color Type | Emotional Tone | Suitable For |

|---|---|---|

| Metallic Finishes | Luxury spark | Compact Cases |

| Gradient Colors | Artistic storytelling | Mascara Bottles |

Is testing samples before mass production truly worth the extra days?

Those few days are a rehearsal before opening night:

- Exposes flaws early—misaligned Label Application or imperfect Metallization vanish before they mar thousands of units.

- Confirms that intended Satin Finish will gleam exactly as envisioned.

One careful preview prevents a chorus of costly regrets later.

References

- Beauty and Personal Care Packaging: Key Trends and Innovations – Euromonitor.com

- Sustainable Cosmetic Packaging Trends Set to Transform Beauty in 2026 – packnode.org

- The Future of Beauty Packaging: Here’s What This Means for Your Brand – mintel.com

- Beauty Consumer Trends: Key Insights from the Voice of the Consumer Survey – Euromonitor.com

- Smithers forecasts global packaging market to grow – smithers.com