Heavy-wall PET vs Glass: Which is better for foundation bottles?

Glass or plastic? It’s the million-dollar question for beauty brands juggling elegance with efficiency. When it comes to foundation bottles, “Heavy-wall PET vs Glass” isn’t just a material debate—it’s the frontline of your product’s first impression. Buyers are under pressure to pick a bottle that won’t shatter in transit, doesn’t send shipping costs through the roof, and still screams luxury on the shelf.

Truth is, what looks glamorous in a showroom might be a diva behind-the-scenes—fragile, expensive, and high-maintenance. Meanwhile, PET has been hitting leg day at the gym: strong build, sleek transparency, and light enough to make your freight bill blink twice. We’re talking about materials that shape not just how your brand feels in hand—but how much it eats into margins.

If you’ve ever had glass break mid-pallet or watched consumers side-eye plastic as “cheap,” this one’s for you. Keep reading—you may never look at packaging the same way again.

Understanding Heavy-Wall PET vs Glass for Foundation Bottles

Choosing between Heavy-wall PET and soda-lime glass? Here’s how they stack up when it comes to foundation packaging—looks, performance, and sustainability all matter.

Key Characteristics of Heavy-Wall PET Plastic

- Durability & Shatter Resistance: This plastic doesn’t crack under pressure. Drop it, toss it—Heavy-wall PET is built to bounce back.

- Lightweight Advantage: Compared to glass, this material cuts down on shipping weight and cost big time.

- Design Flexibility: Custom shapes? No problem. The molding process allows wild creativity without compromising function.

- Barrier Properties: It’s got decent resistance against oxygen and moisture—good enough for most foundation formulas.

- Recyclable PET: Yep, it’s eco-aware. Brands can tap into the growing demand for circular packaging.

And let’s not forget—it still gives off a premium vibe without the weight of glass.

Advantages of Soda-Lime Glass Material

- Chemical Inertness: Zero interaction with even the most sensitive formulations—ideal if your product includes actives like retinol or vitamin C.

- High Transparency: Want that ultra-clear look that screams luxury? This stuff nails it every time.

- Non-Porous Surface: No absorption means no contamination risk over time—a win for long shelf life.

- Premium Feel & UV Protection: Heft in hand plus natural UV filtering properties make this a top-tier choice.

While heavier than plastic, soda-lime glass brings a high-end aesthetic that’s hard to beat in prestige beauty lines.

The Role of Injection Blow Molding in Production

This process is where precision meets scale:

- First, molten resin is injected into a preform mold—this sets the neck dimensions perfectly.

- Next, air blows the preform into its final bottle shape inside another mold.

- Throughout this method, material distribution is tightly controlled so walls stay evenly thick.

The result? Consistent quality across batches with minimal waste. For brands chasing tight tolerances and fast turnarounds, injection blow molding is a go-to solution—especially when crafting complex containers or bottles from PET plastic.

Evaluating Chemical Inertness and Transparency

Let’s break this down real quick:

• If your formula includes reactive ingredients like acids or peptides, you need something inert—that’s where glass wins hands down. Its surface won’t mess with your product’s chemistry.

• For transparency lovers? Both materials shine here: glass offers classic clarity while heavy-wall PET mimics it surprisingly well thanks to advanced polymer tech.

• And when it comes to photostability? Glass edges out slightly due to natural UV resistance—but newer grades of PET are catching up fast with added stabilizers baked right in.

In short: both do the job well—it just depends on what your formula demands most.

Comparing Durability Between Materials

Short bursts:

Glass looks slick but breaks easy if dropped—even tempered variants don’t always survive impact from bathroom tiles.

Heavy-wall PET? Practically unbreakable under normal use. It takes hits like a champ while keeping its form intact—and that makes it ideal for travel kits or clumsy hands alike.

Still want luxury without fragility? Brands often go hybrid: PET outer shell + inner pouch systems offer style plus safety in one neat package.

Sustainability Considerations in Packaging Choice

Grouped by material type:

For Heavy-Wall PET

- Made from recyclable polymers

- Lower carbon footprint during transport

- Compatible with existing recycling streams

- Lightweight = less fuel used per shipment

For Soda-Lime Glass

- Infinitely recyclable without degradation

- More energy-intensive during production

- Heavier = more emissions during shipping

- Often reused in refill programs due to durability

Eco-conscious brands weigh these trade-offs carefully—and some even offer both options based on regional preferences or logistics networks. One brand doing this smartly? Topfeel Makeup—they tailor solutions based on client needs without compromising design goals or sustainability targets.

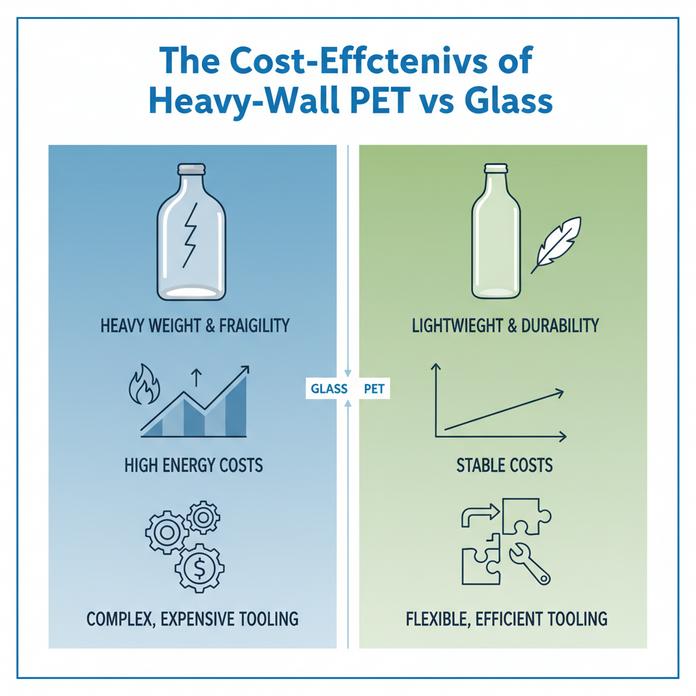

The Cost-Effectiveness of Heavy-Wall PET vs Glass

Let’s break down where your packaging money really goes when comparing heavy-wall PET vs glass containers.

Analyzing Raw Material Price Fluctuation

PET resin prices tend to bounce less than glass, keeping budgets steadier. Here’s how the materials stack up:

— PET resin pricing is closely tied to crude oil, but fluctuations are often buffered by global supply chains. — In contrast, glass raw materials like silica and soda ash are more susceptible to regional shortages or energy price spikes. — During supply chain disruptions, PET shows more resilience due to its lighter logistics footprint and broader sourcing options.

So when you’re juggling costs across quarters, heavy-wall PET gives you fewer surprises than glass does.

Transportation Costs: PET vs Glass Bottles

Shipping heavy-wall PET versus glass isn’t just about weight—it’s a whole cost-saving strategy if done right.

Step 1: Compare bottle weights. Heavy-wall PET bottles weigh significantly less than their glass counterparts, slashing fuel consumption during freight.

Step 2: Factor in breakage rates. Glass is fragile; broken units mean replacements, delays, and extra packaging materials.

Step 3: Look at logistics efficiency. Higher packaging density with PET allows more units per pallet, cutting down on trips.

Step 4: Don’t forget the environmental angle—lower shipping emissions from lighter loads reduce your brand’s overall carbon footprint.

All told? Shipping with heavy-wall PET makes your wallet—and maybe the planet—a little happier.

Tooling and Mold Investment: A Comparative Overview

Setting up production lines for bottles isn’t cheap—but it’s a lot cheaper with heavy-wall PET than with glass.

Glass manufacturing demands high initial capital outlay due to expensive glass molds, longer lead times, and shorter mold lifespan under high heat conditions. On top of that, switching designs mid-cycle can be painfully slow and costly due to rigid tooling systems.

By contrast, producing heavy-wall PET uses flexible methods like injection molding followed by blow molding, which require lower upfront investment in tooling and allow quicker changeovers between designs. The result? Faster market response times without draining your budget on every iteration.

When it comes down to smart spending on production setup, heavy-wall PET easily edges out traditional glass solutions—especially if you’re eyeing scalability or frequent design tweaks.

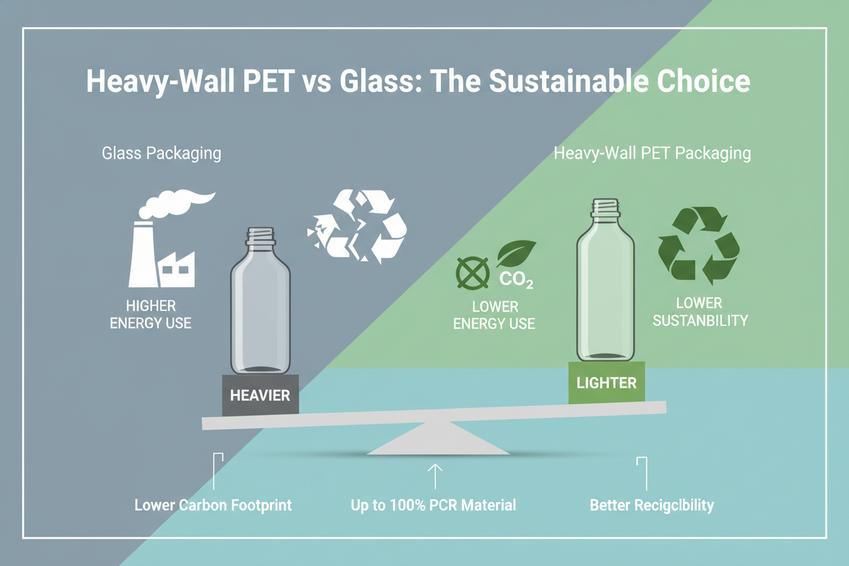

Environmental Impact: Heavy-Wall PET vs Glass

Exploring how heavy-wall PET compares with glass in sustainability, recyclability, and sourcing—without getting too technical.

Recyclability and the Circular Economy

Heavy-wall PET bottles are killing it when it comes to recycling rates, especially compared to traditional glass containers that often get tossed due to contamination or collection gaps.

- Many municipalities now support curbside recycling for PET, boosting its role in closed-loop systems.

- Glass can be infinitely recycled—but only if it’s clean and sorted correctly, which rarely happens at scale.

- PET’s lighter weight means fewer emissions during transport post-consumption, aiding in waste reduction efforts.

The kicker? PET is easier to incorporate into modern packaging innovations thanks to its adaptability for circular design, while glass remains bulky and brittle.

Reducing Carbon Footprint: PET vs Glass

Let’s break down where heavy-wall PET wins out over glass when we talk carbon impact:

🟢 Manufacturing impact

- Making new glass requires high heat—tons of energy.

- Producing heavy-wall PET uses less heat = lower overall energy consumption.

🟡 Transportation footprint

- Glass is heavier = more fuel needed = higher emissions.

- Lighter PET dramatically slashes the transport-related GHG reduction potential.

🔵 Life cycle assessment

- Full cradle-to-grave studies show that heavy-wall PET consistently beats glass on total carbon emissions, especially in single-use formats.

In short? If you’re eyeing a lower environmental impact from start to finish, heavy-wall PET packaging leads the pack.

Post-Consumer Recycled Content Usage in Packaging

When it comes to sustainable upgrades, post-consumer content is where things get real:

• Heavy-wall PET containers can now include up to 100% certified PCR material without compromising strength or clarity—a big win for reducing reliance on virgin resins.

• Unlike recycled glass, which often suffers from color inconsistency and brittleness, recycled plastic maintains better uniformity in shape and performance across batches—key for maintaining high-quality standards across the supply chain.

• Brands pushing hard into sustainable packaging are prioritizing high-PCR-content options because they directly contribute to cutting down on raw material usage and improving overall packaging circularity through smarter material recovery strategies.

This shift is transforming how we think about packaging—from wasteful afterthoughts into champions of eco-efficiency powered by smart use of recycled content.

Sustainable Sourcing Initiatives: What to Know

Sustainability starts long before anything hits the shelf—and sourcing plays a huge part in that game:

A growing number of manufacturers are demanding full-on supply chain transparency. This means tracing raw materials back through certified origins tied to responsible land use practices—especially important when comparing materials like sand-mined silica for glass versus plant-derived feedstocks used in some forms of bio-PET.

At the same time, companies are leaning into third-party certifications focused on ethical sourcing and environmental compliance. These aren’t just buzzwords—they’re becoming table stakes for any brand serious about reducing their footprint while improving supplier engagement metrics across global operations.

Heavy-wall PET solutions have gained traction here because they’re easier to audit across suppliers than fragmented global networks used for traditional glass production. That makes them a go-to choice when aiming for better alignment with corporate goals around long-term environmental stewardship using truly sustainable cosmetic packaging.

Customer Preferences: Heavy-Wall PET vs Glass Bottles

A quick look at how skincare and cosmetic buyers lean when it comes to choosing between heavy-wall PET and glass packaging.

Popularity of Foundation Products in Heavy-Wall PET

• Consumers are drawn to the lightweight nature of plastic packaging, especially for daily-use items like foundation. No one wants their makeup bag weighing a ton.

• Durability matters—foundation bottles made from heavy-wall PET resist breakage way better than their glass counterparts, which is a win for clumsy mornings.

• Brands love that heavy-wall PET allows for sleek, modern designs without sacrificing product safety or aesthetics.

Luxury Cream Jar Containers: A Glass Preference?

- The tactile experience of holding a cool, smooth glass jar gives off an unmistakable sense of luxury—like you’re treating yourself every time you apply your cream.

- For high-end brands, the weight and transparency of glass scream “premium.” It’s not just about looks—it’s about feel and perception too.

- Sustainability-wise, many consumers associate glass packaging with recyclability, even if that’s not always the full story.

Trends in High-End Skincare Packaging Design

✦ Minimalist vibes dominate—clean lines and muted tones are winning hearts across demographics.

✦ Materials matter more than ever; brands are mixing things up with bio-resins, refillable formats, and yes—hybrid blends of PET plastic and glass-like finishes.

✦ Customization is key; unique shapes help define brand identity while still maintaining that luxe feel consumers crave from their skincare packaging.

Foundation Products Are Going Lighter—and Smarter

The shift toward heavy-wall PET for foundations isn’t random—it’s strategic. Portability meets performance here: people want something travel-ready yet stylish enough to sit on their vanity. Unlike traditional thin plastics, these bottles have a heftier feel without being actual glass—a middle ground that works well for mid-tier beauty lines aiming to elevate perception without increasing fragility or cost.

What Makes Glass Feel Premium?

Short answer? Everything about it—from its glossy surface to its satisfying weightiness—tells your brain “this is special.” For creams especially, where indulgence is part of the ritual, customers often prefer something they can display proudly on their shelf. That said, new formulations using thick-walled polymers are starting to mimic this effect quite convincingly…without the risk of shattering when dropped on tile floors.

Material Innovation Meets Consumer Demand

– In response to rising demand for sustainable solutions: • Brands are testing out biodegradable alternatives alongside traditional materials. • Some combine recycled content into existing bottle molds. • Others explore refillable systems using both glass and advanced polymers like upgraded PET containers.

– According to Mintel’s Beauty & Personal Care Report Q2/2024: “Consumers increasingly expect eco-consciousness without compromising visual appeal.”

– This dual focus on aesthetics + sustainability has pushed manufacturers toward hybrid approaches blending form with function in clever ways.

Why Consumers Still Love Glass Jars for Creams

• Visual appeal: Nothing beats how luxurious a clear or frosted jar looks under soft bathroom lighting.

• Perceived value: Heavier = pricier in many minds—even if what’s inside is identical across formats.

• Ritualistic use: Dipping fingers into a cool jar feels more pampering than squeezing from a tube or pump bottle made from even premium-grade plastic like heavy-wall PET.

But don’t count out thick-walled plastics just yet—they’re catching up fast by mimicking those same sensory cues while offering better drop resistance and lighter shipping weights.

Comparing Shelf Presence Across Packaging Types

Glass jars still dominate retail shelves for ultra-luxury creams because they offer unmatched shine and clarity under store lighting—but when it comes to foundations or serums targeting younger audiences? Sleek matte-finish bottles made from engineered polymers like upgraded PET composites are stealing the show thanks to edgy branding opportunities and ergonomic shapes that stand out online as much as IRL displays.

So while it’s not exactly a war between materials, the choice between glass vs heavy-duty plastic often boils down to what vibe you’re going for—and who you’re trying to impress at checkout time.

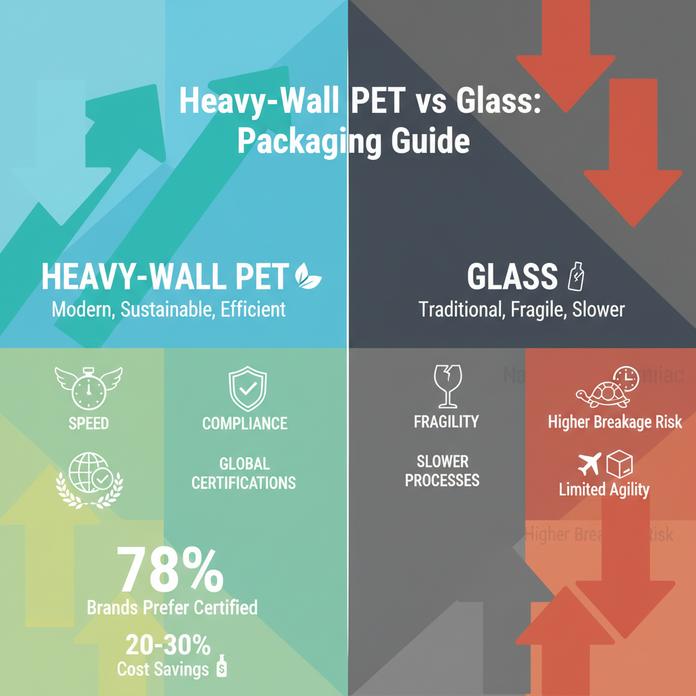

Choosing between Heavy-Wall PET and Glass: A Guide

Picking the right cosmetic container? Here’s how heavy-wall PET vs glass packaging stack up across safety, cost, and production.

Factors to Consider: FDA Compliance Regulations

- FDA compliance is a must for both materials, but the road to approval can look a little different.

- Heavy-wall PET generally clears faster due to its established history in personal care.

- Glass may require more documentation if additives or coatings are involved.

- Watch out for leachables—PET has fewer risks with modern formulations.

- Both must meet regulatory standards, but PET often wins on ease-of-certification.

- In the U.S., Title 21 CFR governs cosmetic containers—know it inside out.

In short, when comparing heavy-wall PET vs glass, PET tends to breeze through red tape faster.

Evaluating Global Packaging Safety Certifications

When you’re shipping worldwide, it’s not just about looks—it’s about meeting every box on the global checklist:

• ISO standards like ISO 8317 and ISO 9001 help ensure structural integrity and process quality. • Many countries require material compliance with REACH or RoHS directives—especially in Europe. • Look for containers with recognized safety seals, such as EcoCert or NSF Certified. • Glass often carries traditional appeal but may lack uniform certifications unless custom certified. • On the flip side, heavy-wall PET often comes pre-certified by global suppliers for multiple regions.

According to a 2024 report by Smithers Pira, “Over 78% of global beauty brands prefer packaging that meets at least two international certification benchmarks before mass rollout.”

Understanding Material Safety Data Sheets (MSDS)

The MSDS isn’t just paperwork—it’s your backstage pass into what your packaging is really made of.

- It details everything from chemical makeup to flammability ratings.

- For glass, expect high thermal resistance but also fragility warnings.

- For PET? You’ll see strong stability under UV exposure and minimal off-gassing risks.

- Both must include proper handling guidelines, especially during transport or filling operations.

- Want peace of mind? Compare hazard levels directly from each material’s MSDS sheet.

So when debating between heavy-wall PET vs glass, don’t just go by feel—check what’s written in black and white on those sheets.

Assessing Operational Overheads and Labor Costs

Choosing between these two isn’t all aesthetics—it hits your bottom line too:

🔹 Operational overheads: Glass is heavier, breaks easier, and needs more care during handling; that means higher insurance costs and slower throughput. 🔹 Labor costs: More labor hours go into cleaning up shattered glass than moving lightweight PET units down a line. 🔹 When comparing total manufacturing expenses, heavy-wall PET usually saves around 20–30%. 🔹 Lower weight = cheaper freight = smaller carbon footprint = happier finance team.

If you’re running lean or scaling fast, this part alone makes a solid case for going with heavy-wall plastic over traditional glass jars.

The Impact of Automated Filling Line Efficiency

Let’s walk through how these materials behave on an automated line:

Step 1: Machines pick up containers — heavy-wall PET aligns easily due to its consistent shape; glass may misalign if slightly warped or chipped. Step 2: Filling begins — lighter-weight PET allows faster fill cycles without risking spillage; glass slows things down due to extra caution needed. Step 3: Capping & sealing — both materials perform well here if tolerances are tight; however, cracked rims on glass can halt entire lines unexpectedly.

From start to finish, automation favors predictability—and that’s where heavy-wall plastic shines compared to fragile glass setups in high-speed environments.

In the end, when looking at efficiency per minute across hundreds of units per hour… plastic pulls ahead fast in this race between heavy-wall PET vs glass options.

Heavy-Wall PET vs Glass: Which Offers Better Protection?

When it comes to packaging, choosing between heavy-wall PET and glass can make or break your product’s safety and shelf life. Let’s unpack the real differences.

High Impact Resistance Strength of Heavy-Wall PET

Heavy-wall PET is built to take a hit—literally—and here’s where it shines:

• Durability: It resists cracks and chips during transportation, making it ideal for high-volume shipping. • Strength-to-weight ratio: Despite being lightweight, its structural integrity holds up under pressure. • Breakage reduction: Unlike glass, which shatters on impact, heavy-wall PET absorbs shocks without splintering.

This combo of toughness and flexibility gives brands peace of mind when shipping fragile contents long distances. That’s why industries like cosmetics and supplements lean toward this material—it’s just more forgiving than brittle alternatives.

Evaluating the Barrier Against Oxygen in Glass

Let’s break it down with some numbers to show how much better glass performs when it comes to oxygen protection:

| Material Type | Oxygen Permeability Rate | Shelf Life Extension | Typical Application |

|---|---|---|---|

| Regular PET | 5–7 cc/m²/day | Short | Water bottles |

| Heavy-Wall PET | 2–4 cc/m²/day | Moderate | Skincare containers |

| Coated PET | <1 cc/m²/day | Higher | Pharmaceuticals |

| Glass | ~0 cc/m²/day | Longest | Perfume, wine bottles |

Glass is practically impermeable—its airtight quality means no oxygen sneaks in to oxidize or spoil the product inside. So if you’re bottling something sensitive like serums or oils? You’re going to want that kind of barrier strength backing you up.

Understanding the Lower Thermal Expansion Coefficient of Glass

Short bursts of heat or cold won’t rattle glass like they might with plastic. Why?

- It has a naturally low thermal expansion coefficient.

- This means less warping under temperature swings.

- So whether it’s stored in a chilly warehouse or exposed to sun during transport, glass stays dimensionally stable.

This kind of performance matters most when precision counts—like keeping airtight seals intact or preventing deformation under stress.

Comparing Durability vs Fragility in Real-Life Scenarios

Here are three quick-hit comparisons based on user experience:

• Drop test from 4 feet? Heavy-wall PET survives; glass usually doesn’t. • Rough handling by couriers? Glass chips easily while heavy-wall PET shrugs it off. • On-the-go use cases? Consumers prefer plastic over fragile containers they worry about breaking in their bags.

That said, some customers still choose glass purely for aesthetics—even if it’s more prone to damage.

Moisture & Gas Barrier Trade-Offs Between Materials

Let’s group key properties together so you can see where each material wins:

🛡️ Barrier Performance:

- Glass blocks both moisture and gases exceptionally well.

- Heavy-wall PET, while improved over regular plastics, still allows minimal permeability unless treated with coatings.

🔥 Heat Tolerance:

- Glass withstands sterilization temperatures.

- Heavy-wall PET melts at lower thresholds but handles moderate warmth fine.

📦 Packaging Flexibility:

- Heavy-wall PET molds into complex shapes easily.

- Glass is more rigid but offers premium feel and clarity.

So depending on what your product needs—protection from air, heat stability, or design freedom—you’ll lean one way or another.

How Topfeelpack Helps Brands Choose Wisely

Choosing between heavy-wall plastic and traditional glass isn’t always black-and-white—it depends on what your brand values most:

Step 1: Define what’s critical—impact resistance? Heat tolerance? Aesthetic appeal? Step 2: Evaluate your distribution chain—is rough handling common or rare? Step 3: Consider sustainability goals—recyclability differs between materials depending on region. Step 4: Test samples from both formats under real-world conditions before scaling production.

Topfeelpack works directly with brands through these steps to make sure their custom cosmetic packaging not only looks great but also protects what matters most inside the bottle.

FAQs about Heavy-wall PET vs Glass

1. What makes heavy‑wall PET plastic attractive for foundation and concealer products?

Light yet strong, heavy‑wall PET plastic protects makeup formulas with style.

- High impact resistance strength keeps bottles safe during transit.

- Superior transparency clarity presents the true tone of cream or liquid inside.

- Automated filling line efficiency supports high-volume cosmetic runs with minimal labor and operational overheads.

Together these traits turn packaging into a reliable part of brand identity, not just a container.

2. How does soda‑lime glass material change product perception in high‑end skincare packaging design?

Its cool surface and subtle weight create an instant luxury impression—key for premium serum bottle selections or luxury cream jar containers. It carries:

① Excellent chemical inertness property guarding delicate ingredients;

② A lower thermal expansion coefficient that supports uniform shape retention;

③ Visual depth loved by buyers chasing prestige aesthetics.

3. Why is the injection blow molding process popular among large-scale cosmetic producers?

Short description + multi-column insight table:

| Core Aspect | Resulting Benefit |

|---|---|

| Precise dimensional control system | Reliable closure fit on mascara and eyeliner components |

| Cost-effective manufacturing solutions | Reduced tooling and mold investment costs compared to glass furnaces |

| High-speed production capabilities | Steady supply chain consistency under global packaging safety certifications |

Each column embodies simplicity meeting accuracy on a compact timeline.

4. How do sustainability actions differ between heavy‑wall PET plastic and soda‑lime glass material?

Recyclability marks their contrast branch line: heavy‑wall PET enables post-consumer recycled content usage within circular economy programs, maintaining FDA compliance regulations standards; glass recycling retains purity but demands more energy input per melt cycle—raising its carbon footprint despite full reusability potential.

5. Is transportation cost truly lighter on the budget when shifting from glass to PET bottles?

Yes—the balance tilts visibly toward plastics:

★ Reduced unit weight lowers fuel-based transportation & shipping expenses up to notable margins;

★ Simplified packing reduces raw material price fluctuation risk during export cycles;

★ The result—a leaner eco-distribution path matching sustainable sourcing initiatives while keeping presentation flawless upon delivery.

6. Which offers stronger barrier properties against oxygen exposure for sensitive creams or serums?

When emotions meet science, borosilicate and soda-lime glass options stand out with a good barrier against oxygen plus excellent chemical inertness property, perfect for long-shelf-life formulations prone to oxidation decay risks. Heavy-wall PET remains impressive for everyday foundations—but those guarding fragile actives gravitate toward sealed serenity inside pristine glass walls compliant with REACH documentation requirements and MSDS verifications alike.

References:

[Plastic and glass bottles, comparison – rosinski.com.pl]

[Packaging Material Use Efficiency of Commercial PET and Glass Bottles for Mineral Water – mdpi.com]

[The Complete Guide to Injection Blow Molding – maiwei-machine.com]

[Why PCR Cosmetic Packaging is Essential for a Greener and More Sustainable Cosmetics Industry – apackaginggroup.com]

[The Future of Beauty Packaging: Here’s What Brands Need to Know – mintel.com]

[Cosmetics Labeling Guide – fda.gov]

[CRP-Standards – ivm-childsafe.com]

[Smithers forecasts global packaging market to reach $1.05 trillion in 2024 – smithers.com]