3 Tips for Choosing Makeup Packaging Manufacturers

You’ve got the perfect product, a killer brand story, and a launch date breathing down your neck—but your packaging’s still stuck in limbo. Sound familiar? Choosing makeup packaging manufacturers isn’t just a box to check; it’s the silent handshake between your brand and your customer. Get it wrong, and your luxury lipstick ends up looking like dollar-store clearance. No pressure, right?

Thing is, beauty brands lose up to 20% of repeat customers because of inconsistent packaging or poor durability, according to McKinsey’s Consumer Packaged Goods report. The stakes are high, and the shelf is crowded. So how do you find a manufacturer that actually gets it—your color codes, your scale, your margins? Buckle up, we’ve got three no-nonsense tips that’ll keep your products looking fresh, fierce, and factory-ready.

Key Points for Winning Big with Makeup Packaging Manufacturers

- Material Know-How Matters: Choose manufacturers with deep expertise in acrylic plastic and glass bottles to ensure durability and eco-friendly options for your brand.

- Color Consistency is Critical: Confirm they use high-quality UV coating techniques to preserve your custom Pantone colors from first run to fifth reorder.

- Finish Isn’t Just a Fluff Factor: Evaluate their frosting process on round compacts—especially how well powder puffs fit without compromising visual appeal.

- Decoration Drives Cost: Hot stamping, silk screening, and metallization may elevate brand perception, but they also impact pricing—know where you can splurge or save.

- Shape Affects Spend: Intricate designs like oval palettes can increase tooling and labor costs, so balance creativity with manufacturability.

- Can They Scale You Smoothly?: Always check if the manufacturer can maintain quality and color consistency when moving from 1,000 units to 100,000.

- Bulk Orders, Bigger Bargains: Bundle items like lip gloss tubes and powder puffs, or request discounts on surface polishing and UV coating for mass production.

- Speed Is A Selling Point: Ask about production timelines and priority shipping options for high-demand items like mascara wands and lipstick cases—because delay means lost sales.

Three Game-Changing Hacks To Identify Top Makeup Packaging Manufacturers

Looking for the real MVPs of beauty packaging? These three expert moves will help you pick out the true pros from the posers.

Assess Material Expertise with Acrylic Plastic and Glass Bottles

• Acrylic vs. glass—both look high-end, but they serve different goals. Acrylic offers lightweight durability; glass screams luxury but adds weight and fragility.

• Ask about material quality and safety standards—a legit supplier should know which plastics are BPA-free and which glass types handle essential oils without leaching. (BPA background: see U.S. FDA guidance.)

• Sustainability isn’t optional anymore. Expect answers about PCR resins (post-consumer recycled), refillable designs, or biodegradable options tied to sustainability in makeup packaging.

• Look for certifications like ISO or SGS reports that prove compliance with international safety norms.

• If a manufacturer can’t explain why double-walled acrylic helps preserve product integrity better than single-wall? Red flag.

• Bonus points if they offer hybrid solutions—like an acrylic outer shell with a glass inner bottle—for both style and function.

How Critical Is UV Coating for Custom Pantone Color Consistency?

Color matching ain’t just art—it’s science when it comes to packaging consistency across batches. Here’s how UV coating plays into that:

- Start by asking if their UV coatings are formulated to resist yellowing over time; that’s key if you’re using lighter Pantone tones.

- Make sure they’ve got experience matching custom colors under varied lighting conditions—sunlight vs LED can shift perception.

- A good coating process locks in vibrancy while protecting against scratches, fingerprints, and fading. (See UV coating benefits for abrasion/rub resistance.)

- “In our Q1 2024 Packaging Materials Report,” Euromonitor noted that over 67% of premium beauty brands cited color fidelity as a top priority in packaging decisions.

- Don’t forget about gloss level control—matte UV coatings can flatten color depth unless adjusted properly during formulation.

- If your brand’s identity hinges on precise hues, you’ll need a partner who treats color science like gospel—not guesswork tied to poor quality control processes.

To back up color accuracy tools, top suppliers standardize with Pantone targets and use spectrophotometers for measurement.

Evaluate Frosting Process on Round Compacts and Powder Puff Fit

Frosted finishes may seem cosmetic-only—but they reveal a lot about a maker’s precision game.

The frosting technique affects grip texture, light refraction, even how fingerprints show up on compacts. A sloppy frost job? It’s instantly noticeable under retail lights.

Puff fit is another silent dealbreaker. Too tight? Customers struggle to use it. Too loose? It rattles around like an afterthought. Great manufacturers obsess over millimeter tolerances here—and often test multiple puff sizes before finalizing molds based on actual use cases tied to their manufacturing capabilities and capacity. Link relevant SKUs like powder puffs to confirm exact fit early.

If your current supplier shrugs off these details as minor? Time to walk away quietly… then run fast.

Four Factors Impacting Packaging Manufacturer Pricing

What really messes with price tags in beauty packaging? These four factors shake things up more than you’d think.

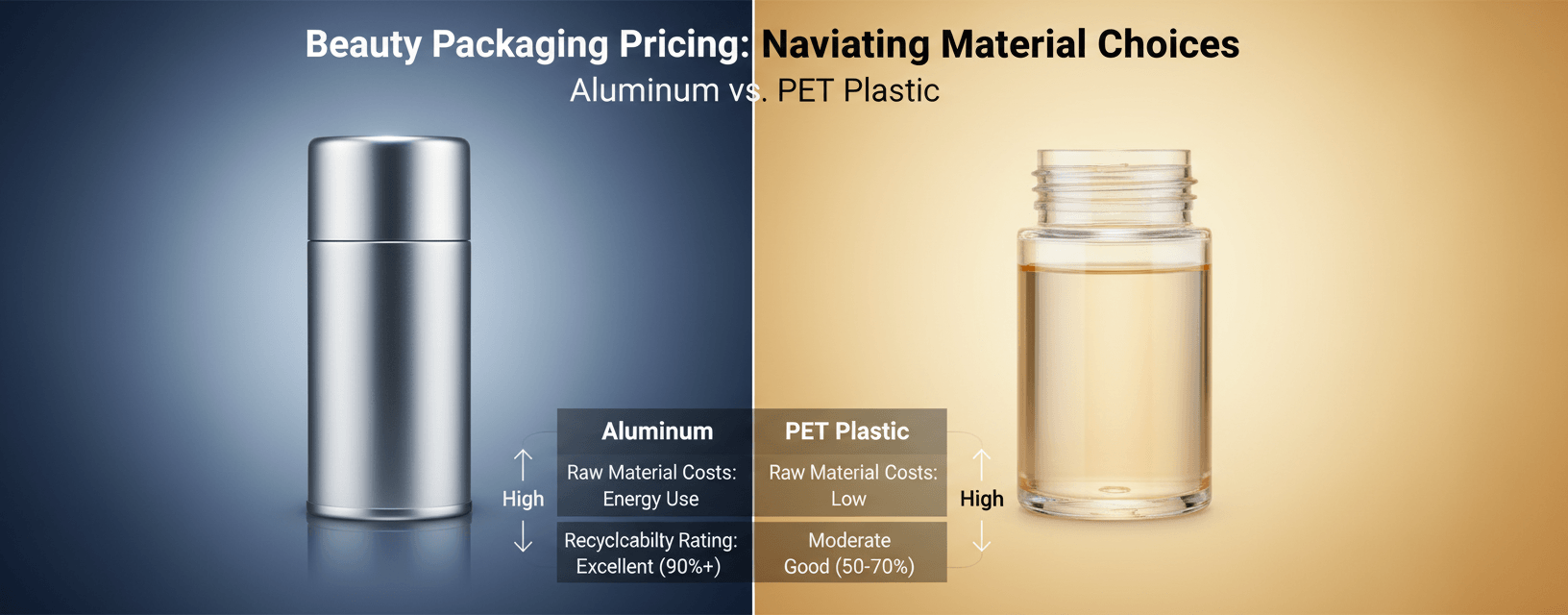

Aluminum Containers vs PET Plastic: Which Costs More?

Material choice is the first fork in the road. Aluminum can look sleek, but it’s not cheap. PET plastic is lighter on both weight and cost—but there’s more under the hood.

- Raw material costs for aluminum are consistently higher than PET due to extraction and refining. (Also note aluminum’s energy intensity vs PET in life-cycle data.)

- Energy costs spike with aluminum because it needs high heat during forming.

- Transportation costs drop slightly for PET thanks to its lower density.

| Material Type | Avg. Cost/kg | Energy Use per Unit | Recyclability Rating |

|---|---|---|---|

| Aluminum | $2.10 | High | Excellent |

| PET Plastic | $1.25 | Moderate | Good |

For sustainability context, aluminum recycling saves up to ~95% of the energy compared to primary production, and PET is widely recycled for packaging—facts your team can leverage in messaging. (International Aluminium Institute)

How Hot Stamping and Metallization Drive Up Prices

Want that shiny gold logo or mirror-like finish? Be ready for a steeper quote.

- Adds extra steps in production, increasing labor costs

- Requires specialized tooling—hello, high equipment and technology investment

- Often slows down production speed, which affects production volume

If you need a primer for your design team, point them to foil stamping basics, and clarify that “mirror” looks typically come from vacuum metallization.

Complex Shapes Like Oval Palettes Increase Manufacturing Costs

Unusual shapes like ovals or asymmetrical compacts might scream “luxury,” but they whisper “expensive” behind the scenes.

Packaging tools aren’t one-size-fits-all. An oval mold isn’t just pricier—it’s harder on machines too. That means:

• Custom molds = higher upfront equipment investment • Slower molding = reduced production volume • Irregular geometry = manual adjustments = increased labor costs

Link your concept sketches early to relevant components (e.g., eye palettes) to pressure-test feasibility with your supplier.

Vacuum Plating and Inner Coating Add Premium to Quotes

These finishing touches may be invisible at first glance—but they show up loud in pricing sheets.

A. Surface Treatments

- Vacuum plating creates that luxe metallic sheen but adds significant energy costs

- Requires cleanroom conditions—raising both overheads and labor costs

B. Functional Coatings

- Inner coatings protect formulas from reacting with packaging materials

- Adds layers of complexity during assembly lines

According to Mintel’s Q1 Beauty Packaging Insights Report (2024), brands using multi-layer inner coatings saw their per-unit packaging cost rise by an average of 17%. That’s a big leap for something you can’t even see—but it matters when product integrity is at stake.

So if you’re working with any makeup packaging manufacturers that offer these extras, expect those quotes to climb fast—especially when customization meets science-backed protection layers.

Can You Scale With Your Manufacturer?

Scaling up isn’t just about more units—it’s about consistency, speed, and control. Let’s break down what really matters when things go big.

Capacity Check for Large-Scale Production of Foundation Bottles

Scaling foundation bottles means more than just turning up the volume. Here’s how to spot if your supplier can keep up:

• Do they have automated mold systems for high-volume SKUs? Without this, bottlenecks are inevitable. • Is their production capacity documented with cycle time metrics? You’ll want transparency here. • Can they shift labor efficiently between lines during demand spikes? Agility is key when orders surge.

A good makeup packaging partner won’t just say “yes”—they’ll show you throughput numbers and downtime logs.

Can They Maintain Custom Pantone Colors at High Volume?

Color matching gets tricky when you’re pumping out tens of thousands of units. Here’s what matters:

- Do they use spectrophotometers for real-time color validation? Machines don’t guess—people do.

- Are there batch control systems in place to prevent pigment drift over time? One off-shade foundation bottle can ruin a launch.

- Is their quality control lab ISO-certified for color accuracy standards? That’s a green flag.

When you’re scaling, consistent color isn’t optional—it’s survival.

Scaling Decoration with Silk Screening and Label Application

Silk Screening: – Automated rotary screen printers for cylindrical bottles and tubes. – UV curing lines that support high-speed drying without smudging.

Label Application: – Inline label applicators with camera-based alignment correction. – Support for variable-size labels across formats.

Inspection Systems: – Vision-based defect detection post-decoration. – Sampling protocols to catch early-stage misprints.

Without scalable decoration, even the best formula looks cheap.

Ensuring Uniform Quality for Lipstick Cases and Eyeliner Tubes

This is where things get tactile—clicks, twists, and smooth glides all need to feel the same, every time.

• Lipstick mechanisms must pass torque resistance tests under heat and cold cycles. Cheap clicks aren’t cute. • Eyeliner caps should maintain seal integrity after repeated use—no dried-out tips allowed.

Reliable makeup packaging suppliers use mechanical stress testers and humidity chambers as part of their quality control process, ensuring every unit feels just right.

Scientific Table – Production Scaling Metrics by Packaging Type

| Packaging Type | Max Daily Output | Defect Rate (%) | Automation Level |

|---|---|---|---|

| Foundation Bottles | 120,000 units | 0.8 | High |

| Lipstick Cases | 95,000 units | 1.2 | Medium |

| Eyeliner Tubes | 105,000 units | 0.9 | High |

| Compact Powders | 80,000 units | 1.5 | Medium |

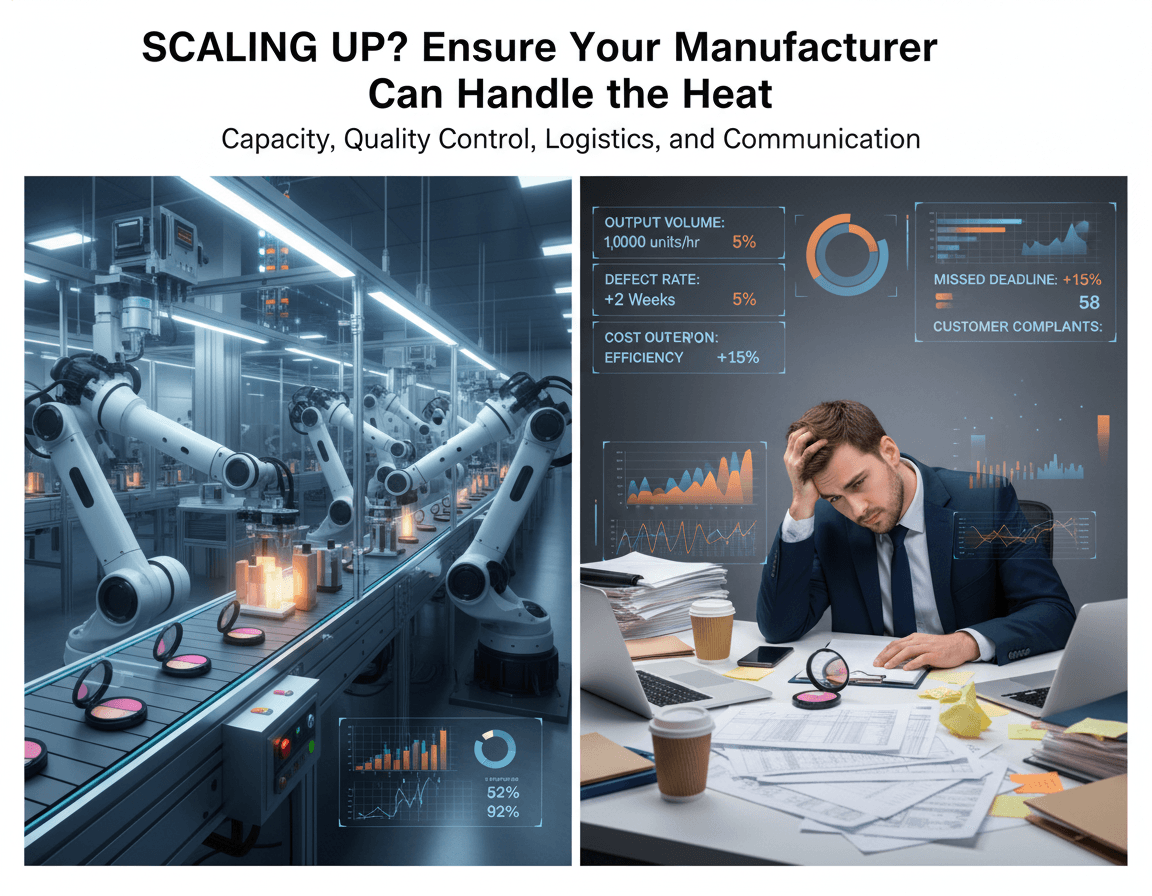

What Makes a Manufacturer Truly Scalable?

Scalability isn’t one thing—it’s a mix of moving parts working in sync: • Strong inventory management systems that prevent stockouts during peak runs. • Flexible tooling setups that reduce downtime when switching SKUs fast. • Transparent communication loops between production and client teams—no surprises.

When your product line grows fast, you’ll need more than capacity—you’ll need coordination.

How Makeup Packaging Suppliers Handle Volume Surges

→ Step One: Pre-load raw materials into local warehouses using predictive demand models tied to your forecast schedule. → Step Two: Activate secondary production lines within the same facility or across partner sites using shared SOPs. → Step Three: Monitor output with real-time dashboards that track throughput and error rates per shift.

A manufacturer that can’t flex on short notice isn’t built for modern beauty cycles.

The Real Cost of Scaling Without Preparation

Short segments on what can go wrong: • Missed launch windows due to slow ramp-up = lost shelf space opportunities at retail chains. • Inconsistent finishes across batches = negative reviews and returns. • Manual rework on packaging defects = ballooning costs you didn’t budget for. • Poor logistics handling = delays getting product into fulfillment centers or DTC channels. • Weak communication = finger-pointing when something breaks down mid-run. Scaling should feel like acceleration—not chaos with glitter on top.

Bulk Orders: Negotiate Discounts With Packaging Manufacturers

Big orders shouldn’t mean big bills. Here’s how to work smarter with your packaging supplier and score serious savings.

Tap into Volume Discounts for Aluminum Containers

- Buy more, pay less—simple math, right? But it only works when you crack the code behind volume discounts.

- Ask about tiered pricing models. Some suppliers drop rates significantly once you hit certain thresholds.

- Don’t just focus on quantity; timing matters too. Ordering off-season can unlock better deals.

💡 Pro tip: If you’re ordering aluminum jars for creams or balms, combining sizes (like 30ml + 50ml) under one SKU family might still qualify as a bulk order.

Bundle Lip Gloss Tubes with Powder Puffs to Cut Costs

- Identify crossover items that share similar mold processes—lip gloss tubes and powder puffs often do.

- Request a bundled quote from your supplier instead of separate ones.

- Factor in shared shipping pallets—it reduces shipping costs for large orders dramatically.

⭑ Bonus move: Ask if they’ll waive mold fees on one item when bundling multiple SKUs together.

This kind of strategic bundling isn’t just smart—it builds stronger supplier relationship management, which pays off long-term.

Want Lower Fees on Surface Polishing for Mass Orders?

| Order Volume | Standard Polishing Fee | Negotiated Rate | Savings (%) |

|---|---|---|---|

| <5,000 units | $0.12/unit | N/A | 0% |

| 5,000–10,000 | $0.12/unit | $0.09/unit | 25% |

| 10,001–20,000 | $0.12/unit | $0.07/unit | 41% |

| >20,000 | $0.12/unit | $0.06/unit | 50% |

When dealing with makeup packaging makers who offer custom polishing (like matte anodizing or brushed finishes), always bring up batch size early in the conversation. Many don’t advertise their flexible rates—but they’re there if you ask nicely and commit to higher minimum order quantity brackets.

Secure Reduced UV Coating Rates on Bulk Runs

“By Q2 of this year, over 68% of beauty packaging producers reported flexible pricing models for finishing services like UV coating.” — Global Packaging Trends Report, May 2024. • UV coating looks luxe but can cost a pretty penny without volume incentives • Ask if your supplier offers sliding-scale pricing based on square meter coverage • Consider consolidating multiple product lines under one production run to meet thresholds

When working with custom packaging pricing, it’s all about finding those hidden levers suppliers are willing to pull… if you ask the right way. And remember—Topfeel’s team knows these tricks inside out and can help tailor your strategy without pushing up lead times or MOQ limits.

Tired Of Delays? Ensure Timely Delivery From Packaging Manufacturers

Packaging delays can cost time, customers, and cash. Here’s how cosmetic brands can keep things moving and avoid the dreaded wait game.

Optimize Production Schedules for PET Plastic Cylindrical Bottles

- Production schedule planning must align with seasonal demand spikes; think summer skincare launches or winter moisturizer rollouts.

- Use supply chain visibility tools like real-time dashboards and vendor tracking systems.

- Set up weekly syncs with your suppliers using clear communication protocols—no more guessing games.

- Run predictive analytics on order patterns to reduce downtime between mold changes.

- Implement rolling forecasts that adjust based on actual sales data, not just projections.

- According to a May 2024 report by Statista, over 62% of delays in plastic packaging stem from inaccurate demand forecasting—not factory issues.

Even if you’re working with multiple vendors across regions, syncing your timelines properly will save you weeks—sometimes months—of headaches.

How Fast Can Manufacturers Dispatch Bamboo Packaging and Glass Bottles?

Natural materials like bamboo and glass bring elegance—but also unpredictability if not managed well.

- Bamboo components often require longer curing times; factor this into your inventory management strategy.

- Glass bottles are fragile during transit—make sure your supplier has robust quality control processes before boxing anything up.

- Ask for historical lead time data from each manufacturer before committing large orders.

- Use third-party logistics partners who specialize in eco-packaging materials for better logistics optimization.

- Always request batch-level testing results before shipment confirmation; don’t assume quality is consistent across runs. A recent McKinsey study from early 2024 found that sustainable packaging lines had a median dispatch delay of seven days compared to plastic counterparts—planning ahead is key here.

Arrange Priority Shipping on Mascara Wands and Lipstick Cases

Running out of mascara wands during a product launch? Nightmare fuel for any beauty brand manager. • Request expedited shipping options upfront—even if it costs more initially, the ROI during peak season is worth it. • Prioritize SKUs by sell-through rate; mascara wands often move faster than lipstick cases depending on trends. • Build redundancy into your fulfillment model by onboarding at least two backup vendors per component type.

Use this quick-reference table when discussing timelines with suppliers:

| Component Type | Avg Lead Time | Rush Option Available | Backup Vendor Ready |

|---|---|---|---|

| Mascara Wands | 12 days | Yes | Yes |

| Lipstick Cases | 10 days | Limited | No |

| Eyeliner Tubes | 14 days | Yes | Yes |

Don’t wait until you’re down to your last shipment box—build safeguards early and stay stocked year-round.

Bonus Tip: Maintain Performance Metrics Across Suppliers

Keep tabs on how each supplier performs—not just once but consistently over time—to avoid repeating mistakes across seasons or launches.

- Track order fulfillment accuracy, especially for high-volume SKUs like lip gloss tubes or foundation pumps.

- Create monthly scorecards using metrics such as defect rate, delivery punctuality, and responsiveness under pressure.

- Rotate underperforming vendors out every quarter unless improvement is shown through hard data—not promises alone.

- Share performance feedback regularly through structured review calls rather than reactive emails after something goes wrong.

Even makeup packaging manufacturers with great reputations can slip up—your job is making sure they catch those slips before they hit shelves under your label.

Final Note: Don’t Just Plan—Rehearse Your Timeline

Before locking in any production run:

- Simulate the entire timeline—from artwork approval through final delivery—to test feasibility under real-world constraints.

- Include marketing teams so launch dates align with product readiness; no point hyping something still stuck at customs!

- Confirm all parties understand their deadlines—and what happens if they miss them.

This proactive rehearsal approach has helped brands like Topfeel cut go-to-market delays by up to three weeks per campaign—a small shift that makes a big difference when speed counts most.

References

- ISO 22716 — Cosmetics — Good Manufacturing Practices (GMP) — Guidelines on Good Manufacturing Practices — iso.org — https://www.iso.org/standard/36437.html

- ISO/IEC 17025 — Testing and Calibration Laboratories — iso.org — https://www.iso.org/ISO-IEC-17025-testing-and-calibration-laboratories.html

- Pantone: What Pantone Guides Are Available? — pantone.com — https://support.pantone.com/hc/en-us/articles/360055031251-What-Pantone-guides-are-available-

- What Is a Spectrophotometer? — xrite.com — https://www.xrite.com/learning-color-education/other-resources/what-is-a-spectrophotometer

- Packaging Standards: A Recipe for Consistency — xrite.com — https://www.xrite.com/blog/packaging-standards-a-recipe-for-consistency

- UV Coatings for Printers (benefits, rub/abrasion resistance) — printingnews.com — https://www.printingnews.com/print-finishing/press-release/10293347/harris-bruno-international-uv-coatings-for-printers

- Foil Cheat Sheet (process overview: hot, cold, digital foil) — fsea.com — https://fsea.com/uncategorized/2020/fsea-and-paperspecs-release-print-decorating-reference-for-designers-foil-cheat-sheet/

- What Is Vacuum Metallization? — topflight.com — https://www.topflight.com/blog/what-is-vacuum-metallization

- Acrylic vs. Glass — Weight & Strength Comparison — acplasticsinc.com — https://www.acplasticsinc.com/informationcenter/r/acrylic-vs-glass

- APR PCR Certification Program (PCR definition & sourcing) — plasticsrecycling.org — https://plasticsrecycling.org/apr-pcr-certification

- The PET Packaging Resin (properties & recyclability) — plasticsindustry.org — https://www.plasticsindustry.org/resin/pet/

- Aluminum Recycling Conserves ~95% Energy vs. Primary — international-aluminium.org — https://international-aluminium.org/about-aluminium/recycling/

FAQs about Makeup Packaging Manufacturers

How do makeup packaging manufacturers keep color consistent across massive orders?

Color matching isn’t just science—it’s an art. When thousands of lipstick tubes need to share the exact same shade, precision becomes everything. Manufacturers rely on:

- UV coatings that seal in Pantone shades like a protective shield

- Automated scanners that catch even the slightest hue shift

- Constant recalibration of printing machines—because one degree off can ruin a whole batch

Each step is obsessive, but it has to be. A brand’s identity can live or die by its colors.

Can they handle unusual shapes like oval palettes or square jars?

Absolutely—but expect a little more complexity behind the scenes. Custom molds must be crafted from scratch, which means longer lead times and higher setup costs. Still, for brands looking to stand out with bold silhouettes, experienced manufacturers know how to make those curves and corners happen without compromising function.

What materials are most affordable when ordering in bulk?

Some options balance price and presentation better than others:

- PET plastic: budget-friendly and lightweight

- Acrylic: clearer than PET but slightly pricier

- Glass: elegant but heavy (and expensive to ship)

- Bamboo: eco-chic yet often comes at a premium

Choosing the right material depends on your product goals—and what story you want your packaging to tell.

Do hot stamping and metallization push up pricing significantly?

Yes—and not by accident. These finishes demand specialized tools, extra labor, and precise timing during production runs. Hot stamping involves pressing foil into surfaces with heat; metallization requires vacuum chambers where pigments become chrome-like sheens under pressure. The final result gleams—but so does the invoice.

Is bundling items like lip gloss tubes with powder puffs actually worth it?

It can be surprisingly smart:

- Cuts down per-unit shipping fees by consolidating space

- Simplifies warehouse logistics—fewer boxes mean fewer headaches

- Often unlocks volume discounts if ordered together

For indie brands especially, bundling turns chaos into control while saving money along the way.

How do I know if a manufacturer can scale my foundation bottle order fast enough?

Ask them hard questions upfront—don’t wait until you’re knee-deep in backorders:

- What’s their monthly output capacity for cylindrical bottles?

- Can they show samples from large recent runs?

- How automated is their filling line?

If answers feel vague or overly optimistic… trust your gut before signing anything permanent.