Best Practices for Cosmetic Plastic Tube Sustainability

The humble cosmetic plastic tube—yep, that little squeezy sidekick in your skincare routine—is under more pressure than ever. Buyers are sweating bullets over how to make packaging greener without blowing the budget or losing shelf appeal. Consumers? They’re reading ingredient lists and judging your tubes like beauty-pageant judges with a recycling bin.

Here’s the kicker: Over 70% of Gen Z shoppers say they’ll drop a brand if its packaging feels wasteful, according to NielsenIQ. That’s not just talk—it’s money walking out the door in eco-friendly boots.

Sustainability isn’t some fluffy buzzword anymore; it’s become a business survival skill. From right-sizing diameters to swapping virgin plastic for PCR and sugarcane blends, smart brands are finding clever ways to cut waste without cutting corners.

You’ve got options—and we’re about to unpack them like a fresh shipment from your favorite supplier.

Key Points in Greener Design: A Cosmetic Plastic Tube Survival Guide

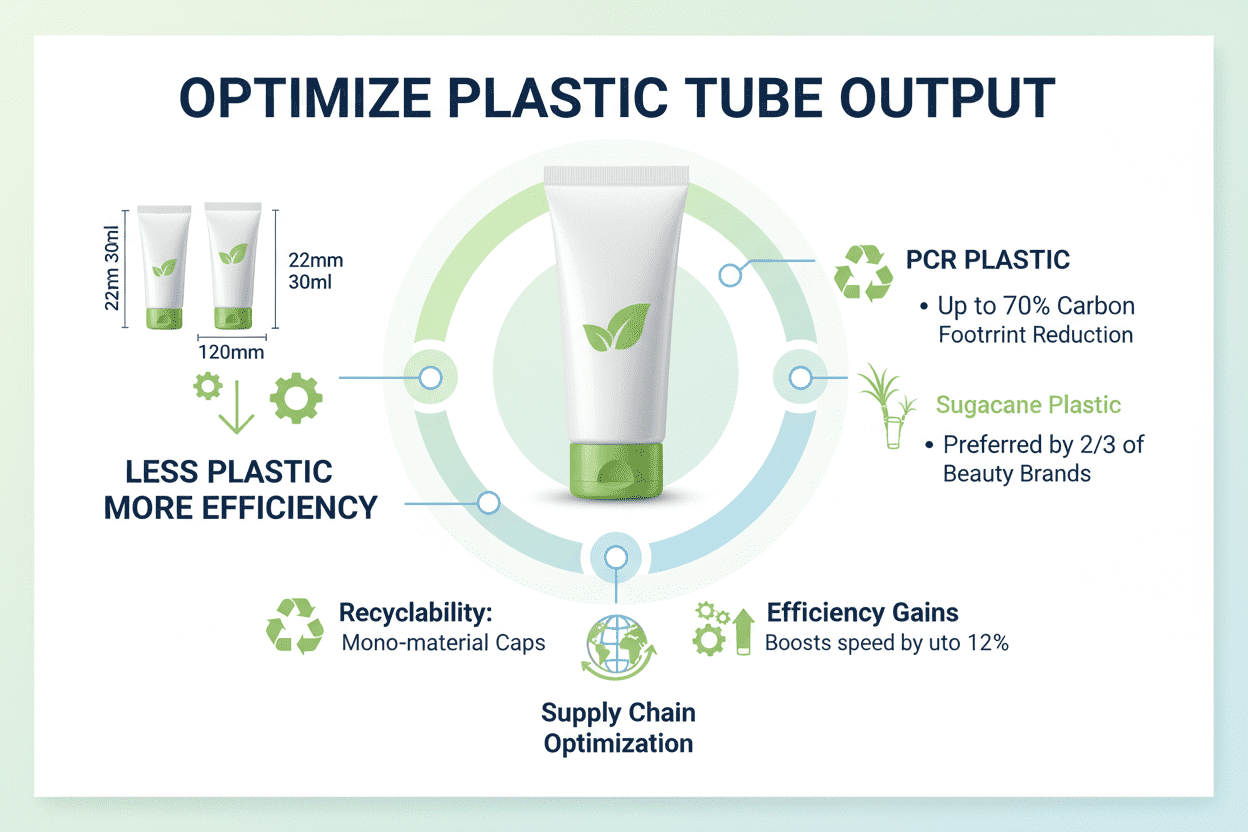

→ Smaller Diameters, Smaller Footprint: Choosing 22 mm diameter 30 ml tubes reduces excess material while keeping lotion packaging functional and sleek.

→ Fill Smart with Length Optimization: Using 120 mm LDPE tubes improves sunscreen fill efficiency, reducing waste across production cycles.

→ Material Matchup Matters: Compare PCR plastic and sugarcane plastic to find the lowest environmental impact without compromising performance.

→ Label Smarter, Waste Less: Streamlining label application processes can significantly cut down on decorative material waste.

→ Built to Last with HDPE Strength: Reinforced HDPE in 25 mm diameter tubes adds durability—less breakage means less replacement waste.

→ Pump Up Performance Sustainably: Airless pump caps protect product integrity over time while limiting contamination risks and leakage losses.

→ Decoration That Holds Up Over Time: Hot stamping resists fading and scratching better than many alternatives for longer-lasting shelf appeal.

→ Supplier Strategy Simplified: Evaluate PET vs PCR suppliers wisely when choosing cleanser tube materials that balance cost, quality, and eco-goals.

→ Size Specs That Fit Your Needs: Establish detailed criteria for selecting trusted vendors of 35 mm diameter / 150 ml capacity cosmetic plastic tubes.

→ Printing Partners Matter Too: Choose silk screen or offset printing providers based on decoration precision and eco-friendly ink use options.

Waste Overflow? Optimize Plastic Tube Output

Finding the sweet spot between sustainability and efficiency in tube packaging is no longer optional—it’s essential.

22 mm diameter 30 ml tubes reduce excess in lotion packaging

- Smaller diameters mean less surface area, which directly cuts down on plastic input.

- A compact profile allows for tighter shipping configurations, reducing freight emissions.

- The format still holds enough product for standard daily use, avoiding over-dispensing.

By switching to this size, manufacturers can maintain usability while trimming back wasteful design choices. The reduced volume also aligns well with minimalist skincare trends, making it a win-win for both producers and eco-conscious consumers. It’s all about smarter material selection, not just less of it.

120 mm length LDPE tubes optimize sunscreen fill rates

Grouped Benefits of the Optimized Length:

Efficiency Gains

- Reduced dead space minimizes underfilling risks.

- Aligns better with automated filling lines, boosting speed by up to 12%.

User Experience

- Easier to squeeze evenly from top to bottom.

- Prevents product buildup at the base due to smart flow dynamics.

Environmental Impact

- LDPE is lightweight and compatible with mono-material recycling systems.

- Shorter tube walls mean fewer grams of plastic per unit—less waste per sale.

When it comes to sunscreen tubes, form meets function at this length. It’s where reducing plastic usage doesn’t compromise performance or shelf appeal.

PCR plastic vs sugarcane plastic for minimal material usage

According to Euromonitor’s Q2 Sustainability Tracker for Packaging Materials in early 2024, “PCR plastics are now preferred by over two-thirds of global beauty brands due to their closed-loop potential.”

Let’s break down key attributes using real data:

| Material Type | Carbon Footprint Reduction (%) | Recyclability Score | Cost Efficiency Index |

|---|---|---|---|

| PCR Plastic | Up to 70 | High | Medium |

| Sugarcane Plastic | Around 50 | Moderate | Low |

While both materials aim toward sustainable goals, PCR edges ahead when targeting minimal material selection, especially when integrated into existing recycling streams. Sugarcane-based options shine in renewability but often fall short on post-use recovery rates.

Streamlined label application cuts decoration waste

Streamlining label processes isn’t just about aesthetics—it saves serious resources:

- Use direct-to-tube digital printing instead of adhesive labels; this eliminates liner waste entirely.

- Opt for water-based or eco-friendly inks, which reduce chemical runoff during production cleanup cycles.

- Integrate heat-shrink sleeves only when branding complexity demands it—otherwise, keep things simple and mono-layered.

- Standardize label dimensions across SKUs so printing batches become more efficient and less error-prone.

Even minor tweaks here can lead to measurable drops in total packaging footprint without touching the formula inside the tube itself.

Why smaller formats drive better sustainability metrics

Shorter descriptions that pack a punch:

• Smaller tubes = smaller carbon trail during shipping due to reduced weight per unit.

• Less resin used means easier integration into closed-loop systems like curbside recycling programs.

• Compact sizing encourages mindful usage—users apply what they need without excess squeeze-outs.

This isn’t about shrinking value—it’s about expanding impact through conscious design rooted in smarter sustainable packaging design principles.

How cap redesign improves recyclability and reduces waste

Step-by-step improvements that go beyond aesthetics:

Step 1: Remove metal spring components from flip-top caps—they complicate sorting facilities’ ability to process them properly.

Step 2: Switch from mixed polymer caps to mono-material HDPE or PP caps that match tube composition—this boosts overall recyclability rates dramatically.

Step 3: Reduce cap height by even just a few millimeters; this small shift trims grams off every unit produced without changing user experience noticeably.

These tweaks sound tiny—but scale them across thousands of units? That’s real impact made easy.

Aligning supply chain choices with eco-efficient tube output

Grouped Tactics Across Operations:

Procurement Adjustments

- Source pre-colored resins instead of post-mold painting; saves energy downstream.

- Choose suppliers certified in low-emission manufacturing standards aligned with ISO14001 guidelines for better tracking across your full supply web.

Production Tweaks

- Consolidate mold tooling across similar SKUs—less downtime, fewer raw material changeovers.

- Automate QC checks using AI-driven scanners; catch defects early and cut rework-related waste piles significantly.

Distribution Smarts

- Ship flat-packed or nested tubes where possible before capping/filling stages.

- Leverage regional fulfillment centers closer to demand zones—cuts transit emissions big time while speeding up delivery too!

Smart moves upstream ripple downstream—and optimizing your entire supply chain is how you really make those efficiencies stick long-term while supporting smarter supply chain optimization strategies throughout production lifecycles.

Educating consumers on proper disposal habits

Here’s how you can nudge people toward cleaner habits without sounding preachy:

• Use QR codes printed directly on tubes linking users straight to local recycling guides based on ZIP code data.

• Add icons showing whether caps should be removed before disposal—a tiny icon goes a long way!

• Share behind-the-scenes stories via social media showing how used tubes get reborn as new ones using recyclability-focused life cycle assessment visuals that stick emotionally as well as factually.

And don’t forget—you’re not just selling products anymore… you’re shaping behavior too through subtle but effective nudges baked right into your primary packaging decisions!

3 Design Tips for Plastic Tube Durability

A few smart tweaks can seriously boost how long your squeeze tubes last—let’s break down three easy wins that make a big difference.

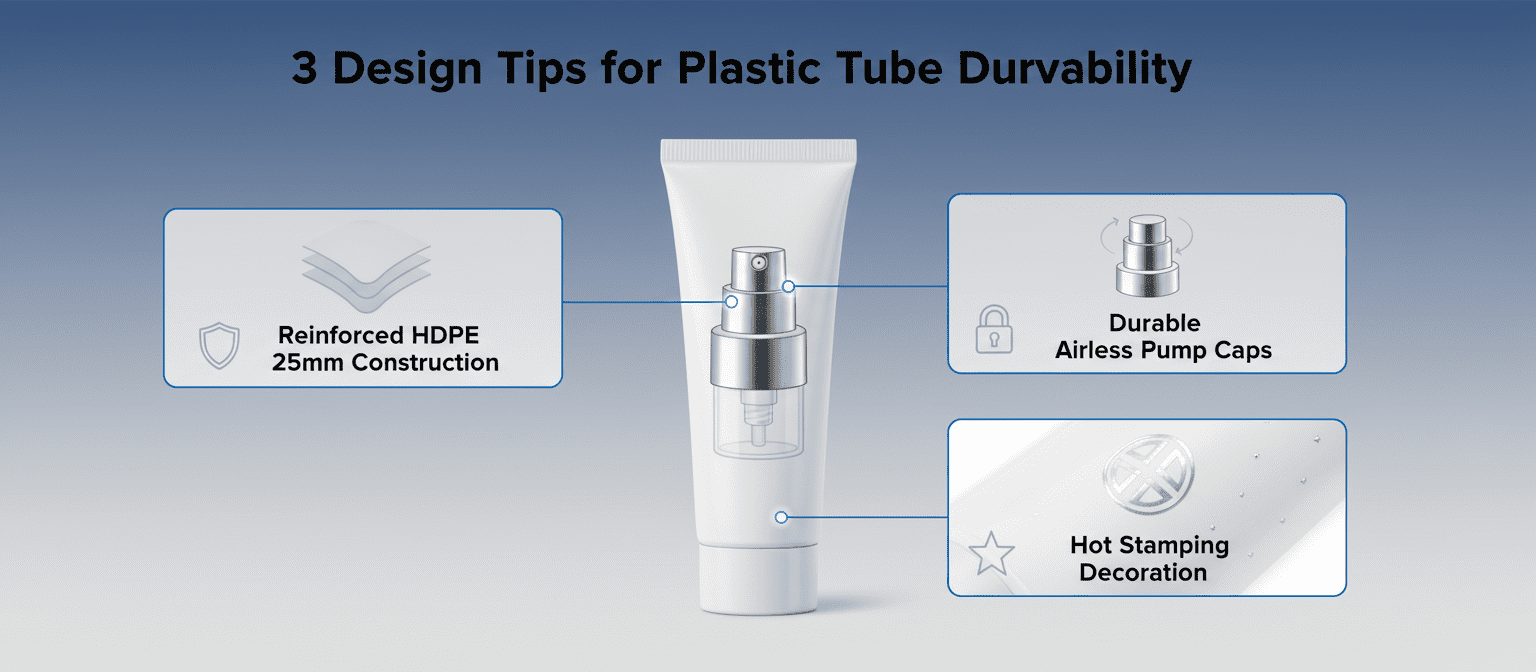

Reinforced HDPE plastic construction in 25 mm diameter tubes

Using HDPE with added reinforcement is like giving your tube a gym membership—it gets tougher and lasts longer. Here’s why it works:

• Cracking under pressure? Reinforced HDPE material resists stress fractures, even when squeezed repeatedly.

• It holds up better against drops and rough handling, especially in transit or on store shelves.

• That 25 mm diameter sweet spot balances flexibility with strength—big enough to hold volume, small enough not to buckle.

This combo makes it ideal for everything from lip balms to travel-size creams, where durability matters just as much as looks.

Durable airless pump caps for long-term performance

To keep the contents fresh and flowing right, you want a cap that pulls its weight. Airless pump tops do just that:

- They prevent air from sneaking back into the tube—no oxidation means no funky smells or spoiled formulas.

- Each pump delivers a consistent dose without clogging, even after months of use.

- Less mess, more control—users don’t have to fight the tube or shake it upside down.

When paired with tough barrels like reinforced plastic, these pumps extend product life while keeping things clean and simple.

Hot stamping decoration to resist scratching and fading

Hot stamping isn’t just about looking fancy—it’s built to last through wear and tear like a champ.

✦ Unlike printed labels that peel or smear over time, hot-stamped designs bond directly into the surface of the tube.

✦ The metallic finish doesn’t just pop visually—it stays sharp even after being tossed around in bags or drawers.

✦ It also resists moisture damage better than stickers or ink-based graphics.

If you want your branding to stay crisp from day one till empty bottle day, hot stamping’s got your back—form meets function here in style.

Packaging Chaos? Streamline Tube Supplier Selection

Choosing the right tube supplier can feel like herding cats. Let’s break it all down and keep your packaging decisions clean, clear, and on point.

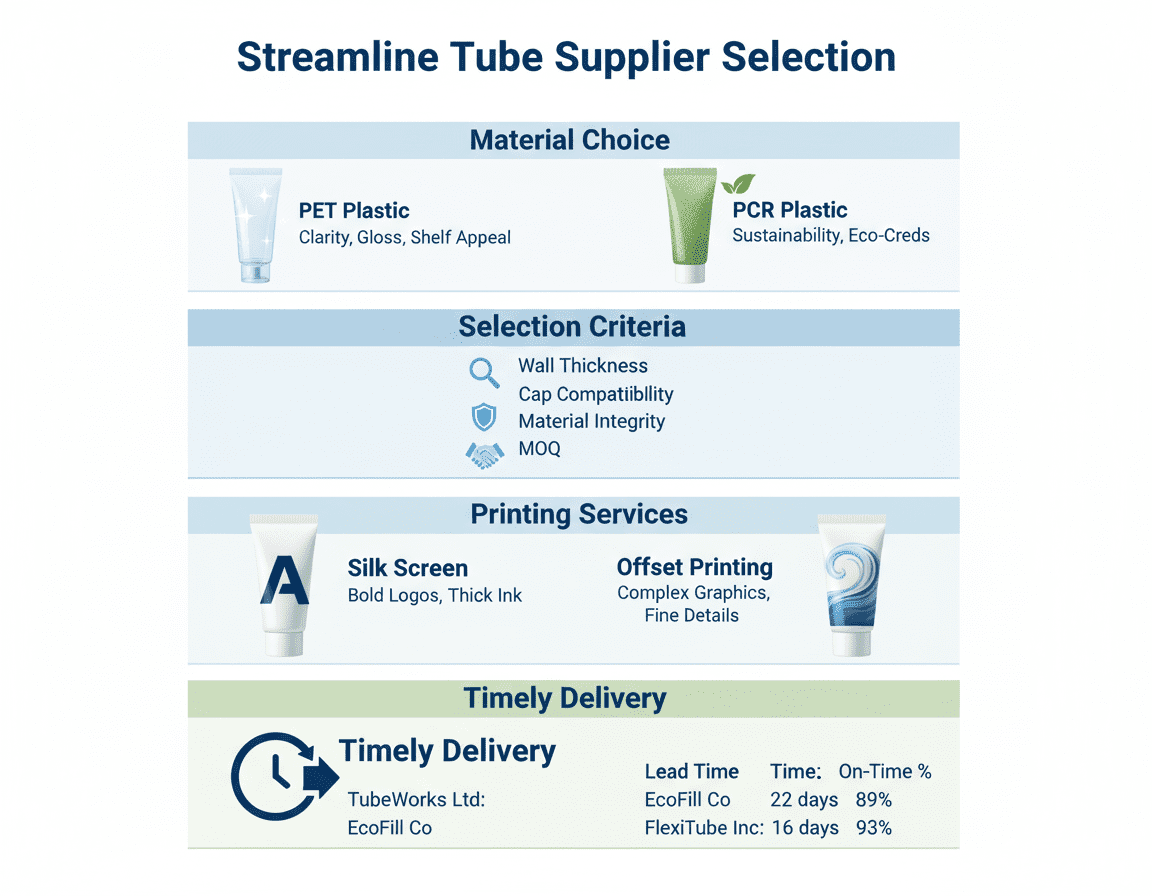

PET plastic vs PCR plastic suppliers for cleanser packaging

When deciding between PET plastic and PCR plastic for cleanser tubes, a few key things should shape your choice:

• Sustainability targets — if eco is your jam, PCR wins hands down.

• Clarity and gloss — PET offers better shelf appeal with its crystal-clear look.

• Cost differences — PCR tends to run higher due to the recycling process involved.

In short, if you’re gunning for that premium sparkle on shelves, PET might be your guy. But if you’re chasing carbon-neutral goals or want to flaunt eco creds on labels, go with PCR.

Selection criteria for 35 mm diameter 150 ml capacity tubes

Let’s talk specs before you shake hands with a supplier:

- Wall thickness tolerance: Consistency matters across batches.

- Cap compatibility: Flip-top or screw-on? Match it to product viscosity.

- Material integrity under pressure: Especially important during transit.

- Customization flexibility: Embossing, matte finishes—can they do it?

- MOQ limits: Can they handle smaller runs without inflating costs?

Evaluating these metrics ensures your tube doesn’t just look good but works flawlessly from filling line to end-user squeeze.

Vendor evaluation: silk screen printing and offset printing services

You’ll need sharp eyes here—printing can make or break how customers see your brand:

— Silk screen printing is ideal for bold logos and thick ink layers that pop off the tube surface; it’s tactile and luxe-feeling.

— Offset printing handles complex graphics better; think gradients or fine text details.

✔ Ask vendors about color matching systems like Pantone use.

✔ Request printed samples under different lighting conditions.

✔ Check drying times and smudge resistance post-printing.

A solid vendor should offer both print types with high fidelity on curved surfaces typical of skincare packaging formats.

Ensuring timely delivery of 120 mm length tubes for hair care packaging

A late shipment isn’t just annoying—it can wreck launch timelines and retail shelf space commitments.

Grouped into three key areas:

⏱️ Lead Time Transparency:

- Reliable vendors provide production + shipping timelines upfront.

- Buffer time must be factored in during peak seasons like Q4.

📦 Inventory Coordination:

- Sync production schedules with filler lines at contract manufacturers.

- Ensure suppliers can store pre-produced blanks if needed.

🧾 Delivery Accountability:

- Use Incoterms clearly in contracts to avoid blame games over delays.

- Track shipments via integrated logistics dashboards where possible.

Here’s a quick vendor comparison table based on delivery performance data from Q1–Q2 of this year:

| Supplier Name | Avg Lead Time (Days) | On-Time Delivery Rate (%) | Backup Stock Available |

|---|---|---|---|

| TubeWorks Ltd | 18 | 96 | Yes |

| EcoFill Co | 22 | 89 | No |

| FlexiTube Inc | 16 | 93 | Yes |

Choose smartly—the right partner saves you more than just shipping headaches; it keeps your brand promise intact every time someone pops open a shampoo cap.

FAQs

A 22 mm diameter strikes a smart balance. It’s slim enough to reduce plastic use but still feels substantial in hand. For lotions and creams, it delivers just the right amount of product with each squeeze—no awkward fumbling or overuse. Plus, its sleek profile makes shelf display more elegant.

- HDPE (High-Density Polyethylene) stands out for durability under pressure—literally.

- When combined with airless pump caps, it shields formulas from air exposure and contamination.

- A 25 mm version is especially good at holding up during travel or long-term storage.

It depends on your brand’s story. PCR (Post Consumer Recycled) tells customers you’re giving old plastics new life—it’s gritty, real-world recycling in action. Sugarcane-based options feel cleaner and greener; they grow back fast and help lower carbon footprints from the start. Both are solid picks—but which one fits your values?

Hot stamping holds strong where others fade:

- It resists scratches even after repeated handling.

- Colors stay vivid—even when exposed to oils or moisture.That means fewer returns due to worn-out branding—and more loyal customers who trust what they see stays beautiful till the last drop.