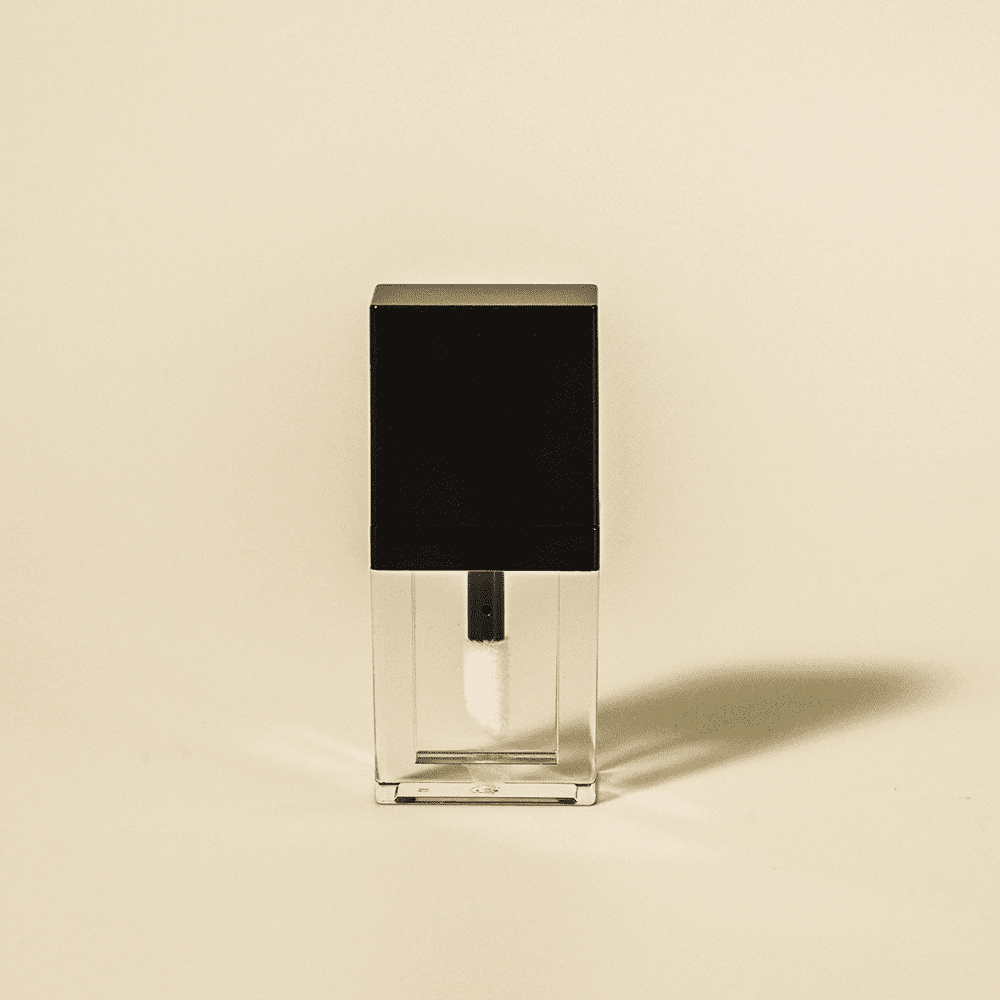

MA-61 Ergonomic Lip Gloss Bottle ODM

Model Number: MA-61

Capacity: 4.5ml

Material: PETG, PP, POM, LDPE

Size: Ø31mm × H70mm

MOQ: 10,000 pcs

Application: Lip Gloss, Lip Oil

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color & Printing

Sample:

Advantages

-

Curved bottle and built-in applicator combine aesthetic appeal with precise, efficient product usage.

-

Compact, travel-friendly design ensures easy grip and seamless application in daily beauty routines.

-

Supports logo, color, and finish customization tailored to brand needs and visual identity.

You May Also Like

View Product Details

Ergonomic Meets Efficiency

Optimized Contour Design

-

Organic Ergonomic Shape The PETG bottle features a rounded, pebble-inspired silhouette with an indented contour, enabling natural hand positioning for ease of use.

-

Transparent Monitoring Window The clear plastic body allows both brands and consumers to monitor formula levels in real time. From a supply chain perspective, this transparency improves inventory QC during the filling and assembly stages.

“Ergonomic packaging is directly linked to consumer retention and repeat usage, particularly in the lip product category,” according to a packaging study by Mintel 2024.

Integrated Applicator System

This packaging solution incorporates an LDPE wand with a built-in doe-foot applicator, directly connected to the PP cap for seamless functionality:

-

The applicator’s angle and length are engineered to reach near the bottom of the vial, ensuring efficient product usage without requiring complex inner structures.

-

The soft tip provides clean pickup and even distribution of lip gloss, lip oil, or liquid lipstick

Designed for Daily Beauty

Comfort in Every Detail

-

Sized for portability and comfort, the container offers an efficient grip and fits into makeup bags or pockets without sacrificing product volume.

-

The threaded neck ensures secure sealing, preventing contamination or spills during daily use.

Custom Fit for Brands

customization capabilities to serve OEM and ODM partners across diverse market segments.

-

Flexible Branding Solutions

This container is compatible with a range of surface finishes, enabling full design flexibility:

-

Color Matching: Tailored hues based on your brand palette, applied through spray coating or pigment molding.

-

Surface Printing: Silkscreen, hot stamping, and UV coating options to achieve matte, glossy, or soft-touch finishes.

-

Logo Integration: Support for embossed or printed branding, ensuring visual continuity across your product line.

-

These customizations are all implemented within Topfeel’s integrated production workflow—from mold design to final assembly

FAQs

-

Color matching using spray coating or tinted plastic

-

Logo application via silkscreen, hot stamping, or labeling

-

Optional surface finishes: matte, glossy, soft-touch, frosted

-

Support for private molds

doe-foot applicator that supports precise and repeatable application:

-

Constructed with LDPE wand for smooth product pickup

-

Reaches near the base of the bottle to minimize product waste

-

Compatible with viscous formulas like lip gloss and

-

Standard Ø31mm base and 70mm height optimize filling and capping systems

-

Tight tolerances support high-speed assembly

-

-

Leakage testing and torque validation for secure closure

-

Abrasion, viscosity, and drop tests for durability

-

Two-color lamp inspection for coating consistency

-

Fully GMPc, ISO 9001, and ISO 22716