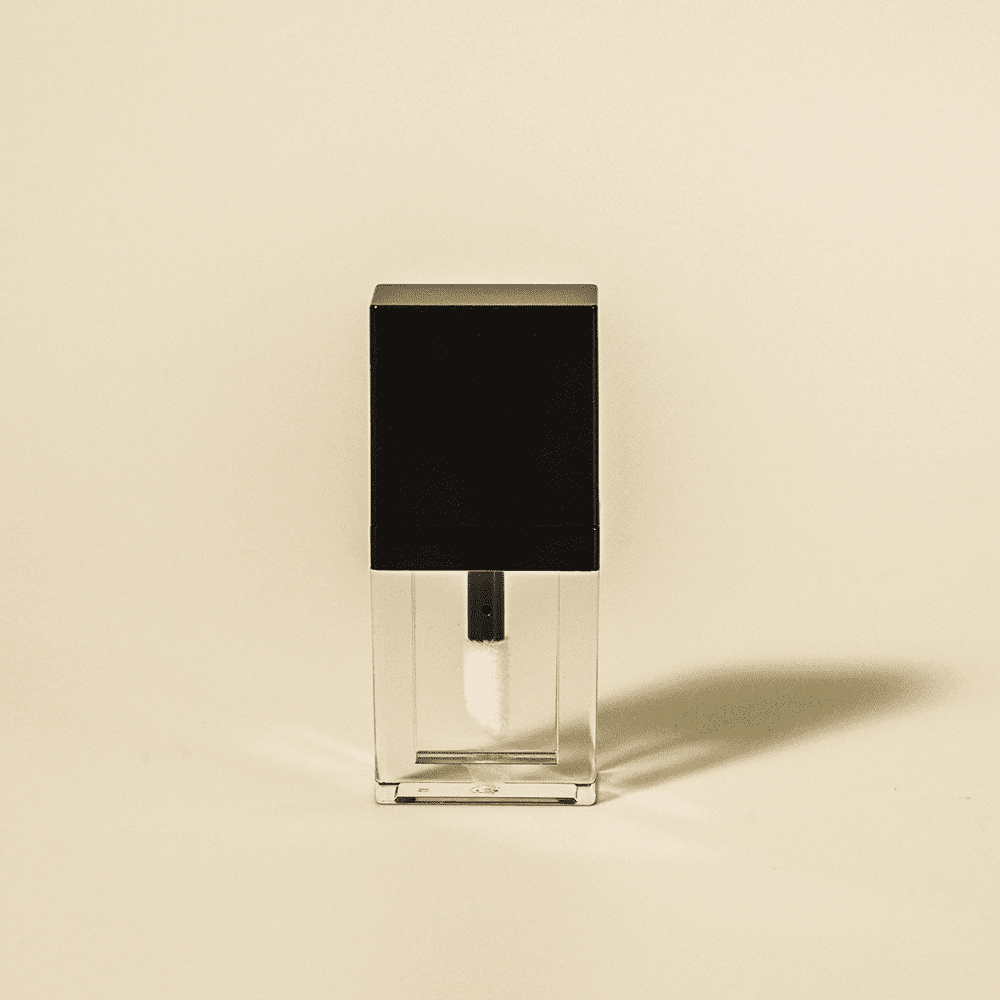

MA-53 Custom Dual Lip Gloss Packaging OEM Manufacturer

Model Number: MA-53

Capacity: 5.2ml × 2

Material: ABS, PETG, PP, PE

Size: L21.7mm × W17mm × H134mm

MOQ: 12,000 pcs

Application: Lip Gloss, Lip Oil, Dual-Use Lip Cosmetics

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color and Printing

Sample:

Features and advantages

-

Double-ended PETG bottles with secure ABS core enable functional dual formulas in a single compact package.

-

Branding-ready ABS center enhances shelf presence while supporting multiple decorative customization options.

-

Multiple customizable components including applicator, finish, and materials provide tailored usability and branding flexibility.

You May Also Like

View Product Details

Dual-Sided for Dual Use

Designed for dual-shade lip gloss or multi-functional cosmetics, the MA-53 lip gloss tube optimizes both capacity and versatility. Its structure supports efficient filling, handling, and application for manufacturers while offering end users a streamlined, portable solution.

-

Independent Dual Reservoirs

-

Each end holds 5.2 ml, totaling 10.4 ml—making it ideal for dual-color or treatment-and-tint concepts.

-

The PETG bottle body ensures transparency and chemical resistance, enhancing compatibility with a wide range of lip gloss and balm formulations.

-

-

Airtight & Balanced Design

-

The ABS connector stabilizes the unit and prevents imbalance during handling, filling, or use.

-

-

“From an engineering perspective, this format resolves two frequent issues: instability during capping and migration between chambers. We engineered the center ABS with structural torque balance to prevent either.” — Zhang Junzhong, Senior Tooling Engineer, Topfeel R&D Center

Visual Impact with Function

-

Branding-Ready Centerpiece

Topfeel offers a full suite of customization options, including:

-

Hot stamping for foil-based logo application

-

Silk-screen printing for multicolor designs or regulatory labeling

-

Injection color-matching for brand-consistent tones on the ABS center zone These features can be executed without altering the product’s mold, ensuring brand alignment while minimizing tooling costs.

-

According to a 2025 report by Beauty Packaging Magazine

Custom Experience, Seamlessly Built

-

Applicator Customization

Choose from different shapes, tip textures, and wand lengths depending on product viscosity and application purpose. Topfeel’s PP applicators can be retooled for glosses, oils, or even lip serums.

-

Aesthetic Personalization

Packaging surfaces can be finished in matte, gloss, pearl, or soft-touch coatings. All treatments are compatible with UV resistance and abrasion testing standards.

-

Clients often opt for neutral or monochrome tones to comply with market trends or region-specific minimalism.

-

For private-label brands, the absence of pre-defined color or texture in this base model makes it an ideal blank canvas.

-

-

Material Adaptability

While the standard version uses PETG, PP, PE, and ABS, Topfeel offers versions in PCR plastics (Post-Consumer Recycled), PLA bioplastics, or refillable structures for sustainability-focused clients. Customization here supports both regulatory compliance and ESG commitments.

FAQs

-

Applicator tip styles (leaf, doe foot, flat, etc.)

-

Center ABS section logo printing or hot stamping

-

Tube color matching and surface finish (matte, glossy, pearl)

-

Material substitutions like PCR or PLA for eco-compliance

-

Filling compatibility and structural adjustments (within mold limitations)

Yes. Its dual-ended design, with two 5.2 ml PETG chambers, supports two different formulations—ideal for gloss and balm combinations or daytime vs. nighttime products. This helps streamline SKUs for hybrid cosmetic product lines.

Yes, the lip gloss tube can be produced using PCR plastic or PLA alternatives. Topfeel’s sustainability program supports clients aiming for refillable, recyclable, or reduced-carbon packaging structures without mold changes.

Topfeel performs thermal, leakage, torque, abrasion, and UV exposure tests on the MA-53, ensuring it passes ISO 9001 and GMPc quality benchmarks. These cover both environmental resilience and structural durability.

Yes. Samples of the MA-53 lip gloss tube can be provided for compatibility testing, custom fit assessments, or pre-launch evaluations. Topfeel’s R&D team also supports quick 3D prototyping upon request.

-

12,000 pieces per SKU

-

Customization or private molds may require a higher MOQ

-