Blue Mascara Tube: Ultimate Guide to Custom Color

Blue mascara tube. Say it out loud—it’s not just packaging, it’s personality in plastic. In a market where half the shelves scream “look at me,” a punch of cobalt or sapphire might be your brand’s secret handshake with the customer. Think less boring container, more stage presence. Studies by Mintel show that 68% of beauty buyers are influenced by packaging color alone.That’s no small potatoes when you’re pushing six figures in inventory and racing deadlines tighter than your last pair of skinny jeans.

Success doesn’t come from slapping on any ol’ shade and calling it custom—nope. It lives in the details: picking materials that don’t dull the pigment, choosing shapes that feel luxe in-hand but efficient on conveyor belts, and locking down color formulas so consistent they’d make Pantone weep.

Quick Answers in Cobalt: Your Blue Mascara Tube Cheat Sheet

➔ Sales Boost from Customization: 5ml blue cylindrical tubes in 10,000-unit runs have shown a 15% increase in sales due to enhanced shelf appeal.

➔ Volume & Shape Impact Repeat Buys: Larger, ergonomic 15ml conical HDPE designs are linked to higher customer retention.

➔ Color Consistency Matters: Standardizing pigment formulas across materials like PET and recycled plastic ensures brand integrity at scale—especially vital for 100,000-unit oval launches.

➔ Material Choice Affects Vibrancy: Recycled plastics may impact color brightness; PET often offers superior clarity for vibrant blues.

➔ Design Combos That Win Attention: Pairings like blue with black accents or clear exteriors with blue interiors elevate perceived quality and innovation.

➔ Production Planning Is Key: Streamline tube molding processes early—especially for high-demand runs of up to 10,000 units—to avoid costly delays.

Data Shows Custom Blue Mascara Tube Increases Sales by 15%

A quick look into how packaging tweaks—size, shape, color, and material—can nudge mascara sales in big ways.

Sales Growth with 5ml Blue Cylindrical Tubes in 10,000-Unit Runs

• Brands using 5ml tubes noticed a tighter grip on impulse buyers. The smaller size feels less risky to try.

• That deep custom blue shade? It’s not just pretty—it boosts shelf appeal when surrounded by neutrals.

• The cylindrical tubes slide easily into small makeup bags, scoring points for portability.

• In test runs of 10,000-unit runs, brands saw up to a 15% lift in sell-through rates compared to generic black packaging.

Shorter runs also allow fast iteration: tweak the tone or finish of the tube and get real-time feedback without overcommitting inventory.

Are 15ml Conical HDPE Tubes Driving Higher Repeat Purchases?

-

A few things make the 15ml format tick:

-

Feels like more value for money

-

Allows for longer product use before repurchase

-

Creates a premium impression

-

The ergonomic grip of the conical design makes it easier to apply on-the-go.

-

Consumers report that the smoothness and flexibility of HDPE tubes give off a high-end vibe.

-

When paired with bold custom colors—especially cool tones like navy or cobalt—the return purchase rate jumped noticeably.

It’s not just about volume; it’s how that volume is delivered that keeps buyers coming back.

PET vs. Recycled Plastic: Custom Color Impact on 10,000-Unit Orders

→ Material choice isn’t just about sustainability—it changes how your color pops:

- PET offers better gloss and clarity, making bright colors look electric.

- On the flip side, recycled plastic has a matte finish that dulls saturation but signals eco-consciousness.

- Across multiple test batches of 50,000-unit orders, brands saw higher initial interest with PET but stronger brand loyalty from recycled options.

In short: if you want bold shelf appeal now, go PET; if you’re playing the long game with values-driven consumers, recycled wins hearts.

Oval vs. Square Shapes in 10,000-Unit Launch Success

- Shape alone can shift perception:

- Sleek oval shapes suggest elegance and fluidity—ideal for luxury branding.

- Edgy square shapes, meanwhile, scream modernity and stand out more on cluttered shelves.

- For large-scale launches at around the 100,000-unit launch mark:

- Oval formats performed better in high-end department stores

- Square ones crushed it in trend-forward online campaigns

Both styles benefit from rich pigment customization—but pairing those shapes with smart color choices (like muted teals or bold sapphire) amplifies their impact tenfold.

The key takeaway? Shape isn’t just aesthetic—it’s strategic branding wrapped around your product.

3 Steps to Customize Your Blue Mascara Tube

Creating your perfect mascara tube is easier than you think. Here’s how to get it right, from materials to shape and volume.

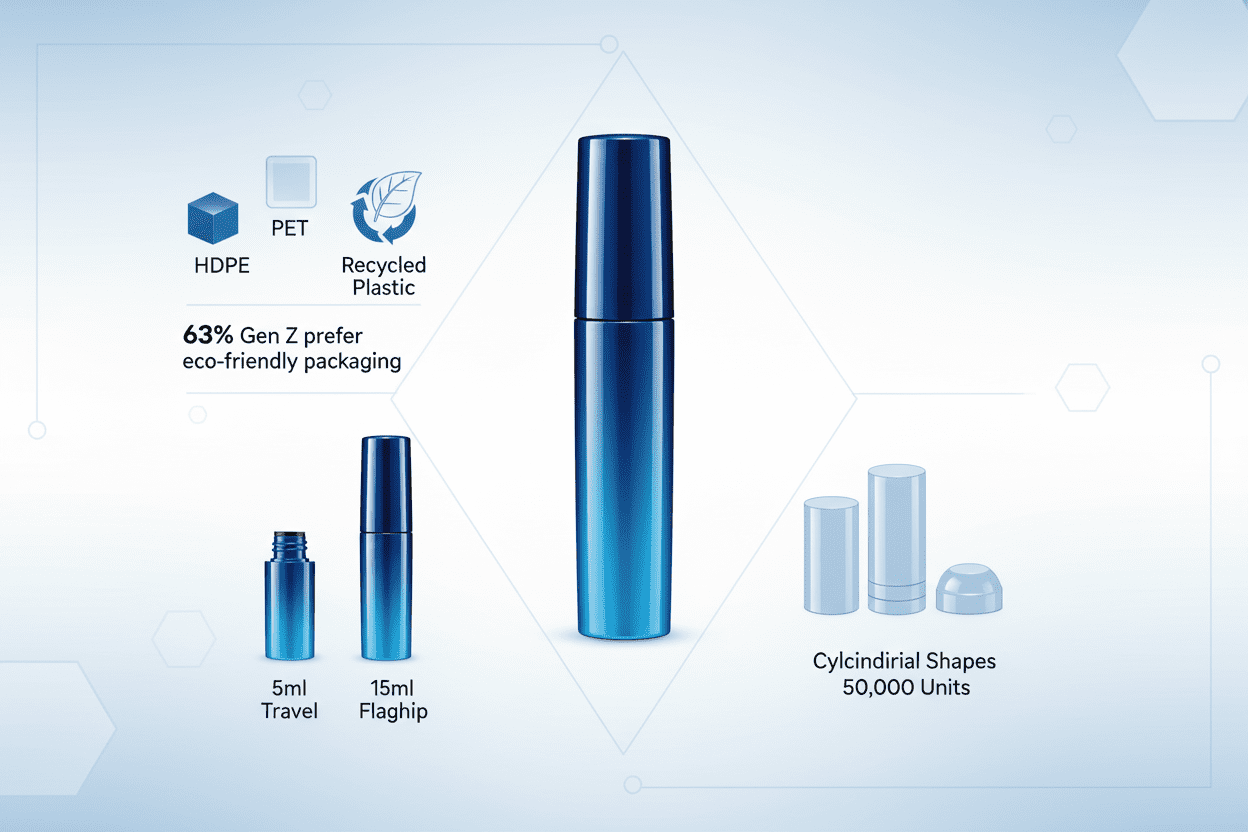

Selecting the Right Material with HDPE, PET, or Recycled Plastic

Choosing the base for your tube isn’t just about looks—it’s about feel, eco appeal, and durability.

• HDPE – A go-to plastic that’s lightweight yet tough. Great if you’re after a no-fuss vibe with solid protection.

• PET – Sleek and glossy, it makes colors pop—ideal for bold branding on smaller tubes.

• Recycled Plastic – The sustainable pick that still holds up under pressure. Consumers are leaning green more than ever.

According to Statista’s Q1 Beauty Packaging Report (2024), over 63% of Gen Z buyers prefer products packaged in visibly eco-friendly materials—a shift brands can’t ignore.

Defining Volume and Color: 5ml vs. 15ml Custom Shades

It’s not just about how much product fits inside—volume changes perception fast.

– A compact 5ml format? Perfect for travel kits or trial runs where portability rules.

– A full-size 15ml option? That’s your flagship—ideal when you want your custom color shades seen loud and proud on shelves.

💡 Don’t forget that subtle tweaks in hue can make all the difference between “meh” and “must-have.” From icy cobalt to deep navy tones, every variation of your blue-based mascara shell counts.

Finalizing Shape and Quantity for 10,000-Unit Cylindrical Runs

When you’re staring down large production numbers like 10,000 units, every detail matters—and that starts with shape.

Grouped Considerations:

- Shape Decisions: Cylindrical is classic—but even within that frame, there are choices like flat caps vs domed tips.

- Production Flow: Streamlined designs reduce molding time; that means faster delivery cycles.

- Market Fit: Bulk runs need mass appeal; test-market feedback often favors smooth contours over edgy cuts.

- Topfeel Insight: Their production line optimizes cylindrical molds with minimal waste—smart choice if you’re scaling fast.

Nailing these elements early saves cash later—and keeps your next run from turning into a costly redo.

What Color Combos Enhance Product Appeal?

Want your tube design to pop off the shelf? Let’s break down which color pairings actually turn heads—and why that matters for your next blue mascara tube concept.

Blue and Black Accents on 10ml Square PET Tubes

Pairing Blue with Black on 10ml Square PET Tubes isn’t just about looking sleek—it’s about signaling edge, class, and confidence. Here’s what makes this combo stand out:

- Visual contrast: The deep richness of black sharpens the vibrance of blue, making both shades more noticeable.

- Premium feel: Black instantly elevates product perception. Add a bold blue and it screams luxury-meets-tech.

- Unisex appeal: This palette isn’t gendered—it works across markets from grooming to skincare.

- Shelf impact: On crowded displays, this duo cuts through the noise without being loud.

- Target audience alignment: Appeals especially to Gen Z and Millennials who associate these tones with trust and authority.

A smart pick if you’re going after a vibe that says “refined but not boring.” Especially strong when used on squared packaging formats like PET tubes where edges frame the color story cleanly.

Mixing Blue with Custom White Coatings for 12ml Oval Containers

When you combine crisp Blue tones with smooth-as-silk Custom White Coatings, something fresh happens—especially on those curved 12ml Oval Containers.

• Clean vibes dominate. That bright white base lets even soft blues glow like neon under sunlight.

• It feels modern without trying too hard—think minimalist skincare brands or boutique cosmetics.

• A little gloss goes a long way; matte white paired with glossy blue details can add texture contrast that grabs attention.

Now toss in some subtle gradients or soft-touch finishes? You’re cooking up something tactile and visual at once. This pairing is especially killer when you want to communicate purity, hydration, or coolness—perfect for everything from eye gels to lightweight mascara variants using small oval containers.

Clear Exteriors with Blue Interiors in 8ml Conical HDPE Tubes

Transparent packaging is having a moment, but adding a twist—like vibrant Blue Interiors inside sleek Clear Exteriors on an 8ml Conical HDPE Tube—takes it next level:

- Layered depth: The clear shell creates dimensionality; users see color before they touch it.

- Product storytelling: A peek at the inner hue hints at formula benefits (cooling? hydrating?) before opening.

- Modern aesthetic: Transparency cues honesty; pair it with rich blue to suggest innovation.

- Compact elegance: The conical shape adds sophistication while keeping portability intact.

This combo works like magic for limited-edition drops or futuristic product lines. And when applied to smaller-volume tubes like those used in travel kits or sample packs? It becomes irresistibly collectible.

Let your design do the talking—and let that inner blue shine through naturally without shouting “look at me.”

Inconsistent Shades? Standardize Pigment Formulas Now

Color mismatch can wreck a product line fast. This guide helps you lock in pigment consistency across materials and formats.

Testing Blue Pigment Consistency in 10ml Cylindrical HDPE Tubes

- HDPE tube surfaces often vary slightly in finish, which can throw off how the color appears under different lighting.

- Even tiny shifts in pigment density during filling can cause visible differences between tubes from the same batch.

- Additives in the plastic may react with certain blue tones, so pre-testing is key before mass production.

- Measure reflectance using a spectrophotometer to catch subtle hue shifts.

- Store filled tubes at varying temperatures—check if color stability holds over time.

- Compare results under daylight and fluorescent light to mimic real-world use.

☑️ Always test on the actual cylindrical format—flat swatches won’t show how curvature affects tone perception.

Color fidelity isn’t just about matching Pantone codes—it’s about preserving that exact cool-blue vibe your customers expect every time they swipe open their mascara.

Short fill lines, temperature swings during shipping, or even a bad batch of base polymer can mess with your blue game. That’s why each production run of these 10ml tubes needs tight control.

Implementing Color QC Protocols: PET vs. Recycled Plastic for 12ml Tubes

Grouped by material type:

• Virgin PET Tubes

- More predictable color absorption

- Less surface haze = truer pigment reflection

- Easier to calibrate shade-matching equipment

• Recycled PET (rPET)

- Slight yellow undertone may skew blue hues

- Higher variability between lots

- Needs tighter QC thresholds per batch

“According to Mintel’s Q1 2024 packaging report, over 65% of cosmetic brands using recycled plastics reported increased costs due to extra visual inspections and pigment adjustments.”

To get consistent results:

- Use calibrated drawdowns from each masterbatch on both virgin and recycled samples.

- Set separate delta E tolerances depending on substrate type.

- Train QC staff to recognize material-specific anomalies—not all hue shifts are pigment-related.

If you’re working with that classic deep-blue mascara look, switching tube material without adjusting your formula is like changing guitar strings mid-song—you’ll notice the discord right away.

Achieving Uniform Custom Shades across 100,000-Unit Oval Runs

Consistency across large runs doesn’t happen by luck—it takes locked-in formulas and vigilant monitoring from the first pour to the last unit boxed.

• Start by locking down a master pigment ratio tailored specifically for oval formats—curved walls reflect differently than flat ones.

• Batch-color validation should include:

- Spectral analysis at beginning/mid/end of run

- Visual checks under natural and artificial light

- Cross-checking against approved golden sample units

• Run automated vision systems at packing stage—they’ll catch any outliers human eyes might miss after hours on the line.

Oval tubes tend to exaggerate gloss levels too, which means even minor inconsistencies in finish or wall thickness can make one unit look darker than another—even if they’re technically identical inside.

By standardizing your formula early and controlling every variable downstream—including fill speed and curing temps—you’ll avoid those dreaded “why does this one look different?” messages from buyers scrolling through online reviews of your latest drop of blue mascara tube variants.

Production Delays? Optimize Tube Manufacturing Timeline

Getting stuck with long timelines and stalled production runs? This guide breaks down how to speed things up without cutting corners.

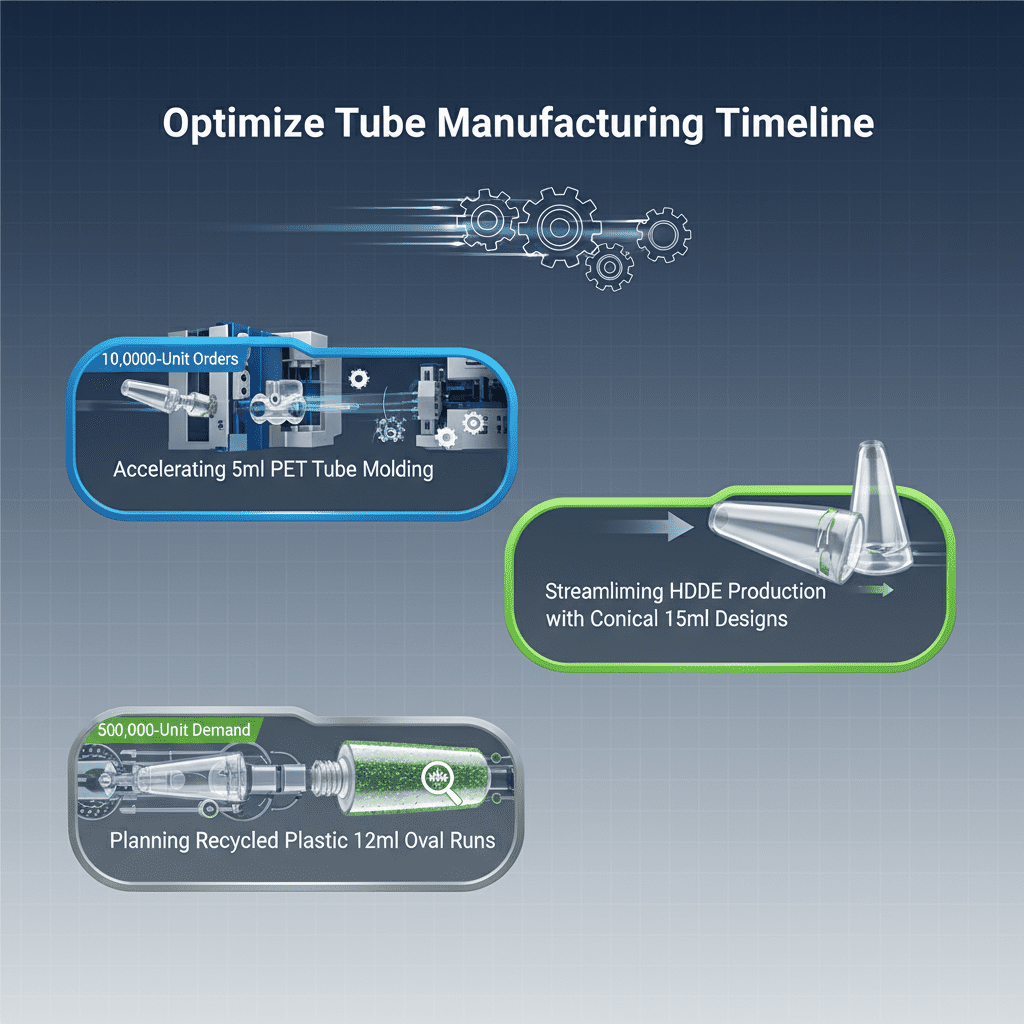

Accelerating 5ml PET Tube Molding for 10,000-Unit Orders

- Shrink downtime by preheating molds before each shift.

- Use hot runners instead of cold runners—less waste, more speed.

- Run a dual-cavity mold setup to double output for every cycle.

To keep your smaller batches moving fast, especially when working with PET Tube materials around the 5ml range, it’s all about cycle time control and predictive maintenance on molding equipment.

Also, tweak your scheduling tactics—batch similar jobs together so you’re not constantly switching materials or mold types when handling those tight 10,000-unit orders.

And hey, if you’re experimenting with a new color or finish like something close to a matte navy blue mascara tube style? Test it separately first—it’ll save you hours later.

Streamlining HDPE Production with Conical 15ml Designs

You want fewer hiccups during production? Start with smart design choices:

• A streamlined conical shape reduces cooling time dramatically.

• Less wall thickness = faster molding = lower energy use.

• Built-in shoulder tapers help eject parts quicker from the mold.

Pair that with using high-flow grades of HDPE, and suddenly your throughput spikes while scrap rates drop off a cliff.

Whether you’re pushing out tubes that mimic the silhouette of a slim blue mascara container or just need consistency across thousands of pieces—design makes or breaks the clock here.

Planning Recycled Plastic 12ml Oval Runs to Meet 500,000-Unit Demand

When you’re staring down half a million units made from recycled stock, planning’s gotta be airtight:

- Lock your supply chain early—recycled feedstock fluctuates like crazy.

- Choose oval tooling that supports multi-cavity molding systems.

- Integrate inline QC checks so you catch defects before they snowball.

- Balance machine usage across shifts to avoid bottlenecks under pressure.

This isn’t just about quantity—it’s about consistency over weeks of nonstop runs using post-consumer resins shaped into compact forms like sleek oval tubes reminiscent of high-end mascara containers.

For massive orders like these, even tiny changes—like switching gate position or tweaking cavity layout—can shave days off timelines while keeping quality locked tight.

FAQs

A vibrant blue catches the eye in ways neutral tones simply can’t. In limited runs—think 10,000 units or fewer—it becomes more than packaging; it’s a silent salesperson on the shelf. Brands using custom blue cylindrical tubes have reported up to 15% higher sell-through rates. The color doesn’t just pop—it lingers in memory.

- Recycled plastic is your go-to when planning over half a million units.

- It holds pigment well, especially across oval and square shapes.

- Customers appreciate sustainability—but only if the product still looks polished and professional.

Absolutely—and doing so adds layers of personality:

- Black accents give square PET tubes a sleek, high-end feel.

- White coatings on an oval shape create contrast that feels fresh and modern.

- A clear outer shell revealing a bold blue core draws attention like nothing else on crowded shelves.

Conical HDPE tubes at 15ml strike the right balance: enough volume to satisfy users, but slim enough to feel elegant in hand. Their ergonomic curve subtly encourages repeat use—people love how they feel while applying their favorite formula. For brands debuting new lines, this form factor often becomes iconic without trying too hard.