Comparison of Custom Cosmetic Tube Options

The packaging aisle isn’t just about holding goop in a tube anymore—it’s a battlefield of brand identity, sustainability promises, and that all-important first impression. If you’re buying in bulk, you know the stakes: one wrong move with your custom cosmetic tube choice and suddenly your high-end serum feels like a dollar-store reject. Materials matter. Caps count. And shelf appeal? That’s your silent salesperson.

In fact, 74% of consumers say packaging design directly influences their purchase decisions. That means everything from the gloss on the finish to whether it’s made from sugarcane or post-consumer plastic could be pushing people toward—or away from—your product.

So here’s the deal: we’re breaking down cosmetic tubes like it’s anatomy class for beauty brands. This isn’t some fluffy overview—it’s real talk about what works at scale when style meets substance… and budget demands answers.

Essential Insights for Custom Cosmetic Tube Success

➔ Material Selection: Understand the differences between LDPE and HDPE plastics, and explore aluminum laminate options for superior product protection.

➔ Key Features: Consider tube diameter, capacity, and cap type to align with your product’s usage and consumer preferences.

➔ Brand Impact: Leverage printing techniques and surface finishes to enhance your brand identity and appeal.

➔ Customization Value: Tailor tube lengths and designs to stand out in a competitive market and meet customer needs.

➔ Sustainability Practices: Embrace eco-friendly materials and innovative recycling methods to reduce your carbon footprint in cosmetic tube manufacturing.

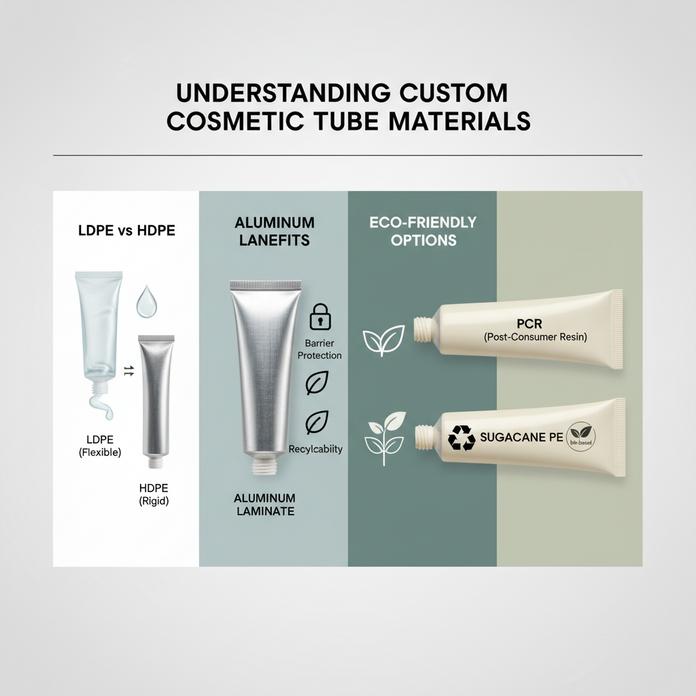

Understanding Custom Cosmetic Tube Materials

Explore how different materials impact the performance, sustainability, and branding of your custom cosmetic tube packaging.

LDPE Plastic vs. HDPE Plastic: Key Differences

- LDPE is super bendy—perfect for squeezable creams.

- HDPE, on the other hand, holds its shape better and resists spills.

- Need see-through tubes? Go for LDPE, it’s got better clarity.

- Flexibility: LDPE bends without cracking—ideal for lotions.

- Durability: HDPE’s rigidity gives it an edge in rough handling.

- Chemical resistance: HDPE wins here—it shrugs off harsh formulas.

• Cost-wise, both are budget-friendly but HDPE may cost slightly more due to its higher density and durability.

For brands wanting a soft touch or a firm grip, the choice between these two forms of polyethylene makes all the difference in how your product feels and functions.

The Benefits of Aluminum Laminate Tubes

- Strong barrier = longer shelf life

- Lightweight = lower shipping costs

- Sleek look = premium brand vibe

- Keeps air out, thanks to high-end barrier protection.

- Locks in fragrance and formula stability

- Boosts perceived value with a metallic shine

• These tubes don’t just look cool—they preserve your product like a pro while offering good recyclability, too.

If you’re selling serums or eye creams that need serious protection from light or oxygen, an aluminum laminate tube keeps things fresh without bulking up your design.

Eco-Friendly Options: PCR and Sugarcane PE

♻️ Want green cred? Try this:

• Use PCR plastic, made from recycled consumer waste • Choose tubes made with renewable sugarcane-based polyethylene (Sugarcane PE) • Cut down on emissions with low-carbon materials

Both options speak volumes about your values—especially if you’re aiming for clean beauty lovers who care about reducing their carbon footprint. These eco picks also blend well into existing production lines without sacrificing quality.

Choosing the Right Material for Your Product

Start by thinking about what matters most:

- Is it all about feel? Go flexible like LDPE.

- Need strength? HDPE’s got you covered.

- Want something luxe? Aluminum laminate brings the shine.

- Going green? PCR or Sugarcane PE says “we care.”

Then match material to purpose:

- Consider your formula’s needs—oily vs aqueous

- Think about shelf presence—matte vs glossy finish

- Factor in cost per unit versus long-term savings

- Align with brand values—eco-friendly vs premium image

From sunscreen to BB cream, there’s no one-size-fits-all solution when choosing a tube material—but getting it right can elevate everything from product performance to shelf appeal.

Topfeelpack helps brands nail every detail of their custom cosmetic tube—from picking materials that match their vibe to delivering Packaging for Cosmetics that actually works in real life.

4 Key Features of Custom Cosmetic Tubes

Choosing the right setup for your custom cosmetic tube isn’t just about looks—it’s about smart packaging that matches your product’s vibe and function.

19mm to 50mm Diameter Tubes: Which is Right for You?

• A narrow diameter like 19mm is sleek, ideal for eye creams or serums. • Wider tubes, up to 50mm, suit body lotions or scrubs with thicker formulations. • Mid-range sizes strike a balance between portability and capacity.

Each size affects how much product you can fit, how it feels in hand, and how cleanly it dispenses. Think about your formula’s thickness and whether users need precision or generous application. For example, lip balm tubes benefit from slim tubes, while exfoliating masks often require wider ones.

Capacity Matters: Selecting the Best Size Option

A quick breakdown:

| Tube Capacity | Volume Range | Ideal Product Type | Target User Frequency |

|---|---|---|---|

| Small | <30ml | Eye cream, spot corrector | Occasional use |

| Medium | 30–75ml | Facial cleanser | Daily use |

| Large | >75ml | Body lotion | Frequent use |

Choosing the right capacity isn’t just math—it’s psychology. If your target user travels often, compact wins. But if you’re selling spa-grade moisturizers? Bigger is better.

Exploring Cap Types: Flip Top vs. Screw On

Here’s the lowdown:

- Flip tops are all about ease—snap open with one hand.

- Screw-on caps are more secure—great when shipping long distances.

- Flip tops suit daily-use skincare; screw-ons make sense for precise treatments like acne gels.

The type of cap affects not only user convenience but also shelf life and perception of quality. A poorly matched cap can ruin even the best formula.

Printing Techniques: Digital vs. Offset Options

Let’s break it down:

- Digital printing = flexibility + speed = perfect for small runs or frequent design changes.

- Offset printing = crisp detail + lower cost per unit at volume = great choice if you’re scaling up production.

Digital gives indie brands agility; offset helps established players keep costs down while maintaining premium branding on every tube surface.

Surface Finishes: Matte vs. Glossy Choices

Matte finishes feel soft and high-end—think luxury skincare vibes with understated elegance. They reduce glare under store lighting and photograph beautifully online.

Glossy finishes? Super reflective, bold colors pop hard, ideal when you want to grab attention fast on crowded shelves.

Both finishes affect how consumers perceive value—even before they twist off a cap or squeeze out a drop of product from their chosen custom cosmetic tube packaging solution.

Custom Cosmetic Tubes: The Role of Branding

Small choices in tube design can spark big reactions. Let’s break down how finishes and printing elevate your brand game.

How Offset Printing Enhances Your Brand Identity

Offset printing brings more than color—it brings clarity, trust, and a vibe that sticks with customers.

- Crisp visuals grab attention fast, especially on crowded shelves.

- High-end graphic quality ensures your logos and product names pop.

- Consistent color accuracy helps reinforce customer recognition over time.

Now add this:

- Brands can tailor every inch—thanks to high-level customization options.

- Sharp lines and vivid hues boost the overall visual appeal, making your packaging memorable.

A 2024 report by Smithers Pira notes that “offset remains the gold standard for premium cosmetics due to its unmatched detail reproduction,” especially for brands prioritizing visual storytelling.

And when you pair offset techniques with smart design? You’re not just selling a cream—you’re building a recognizable brand identity that lives beyond the shelf.

The Impact of Soft Touch Finish on Consumer Perception

That velvety smooth texture? It’s not just pretty—it actually changes how people feel about your product.

🟢 Adds a rich, tactile layer to any cosmetic tube 🟢 Signals higher quality through sensory interaction 🟢 Encourages longer handling time—boosting subconscious brand recall

Grouped benefits include:

-

Emotional Connection:

- The soft texture creates an immediate emotional bond.

- Consumers associate the sensation with luxury and care.

-

Enhanced Shelf Presence:

- Matte yet elegant appearance catches light differently than glossy tubes.

- Makes your packaging look—and feel—more upscale.

-

Stronger Brand Image:

- Reinforces perception of exclusivity and craftsmanship.

- Aligns well with high-end skincare or boutique cosmetic lines using premium packaging strategies.

This finish taps into the power of sensory marketing, turning every touch into a brand moment. When customers run their fingers across a soft-touch surface, it whispers “you’re worth it.”

Varnish Coating: Ensuring Durability and Appeal

Looks fade—but not when you’ve got varnish coating keeping things fresh.

Durability comes first. This protective layer shields against scratches, smudges, and fading from sunlight or oils—perfect for makeup bags or travel kits where wear-and-tear is real life stuff.

Aesthetic shine follows close behind. Whether you go glossy or satin-matte, the right finish adds depth to printed designs while elevating shelf appeal without overpowering the artwork itself.

That combo of protection plus style gives your tube serious staying power—both physically and visually—ensuring long-term value for both product longevity and branding consistency across every single custom cosmetic tube run by Topfeelpack.

Why Customization Matters in Cosmetic Tubes

A custom cosmetic tube isn’t just a container—it’s the handshake between your product and your customer. Let’s break down why smart customization pays off.

Tailoring Tube Length: Small vs. Large Capacities

• Shorter tubes are ideal for travel-size products, testers, or niche formulations with lower product volume requirements. They slip easily into handbags or pockets—super handy on the go.

• On the flip side, longer tubes cater to high-use items like body lotions or cleansers, offering more capacity options per purchase and reducing repurchase frequency.

• Different tube length variations also allow brands to serve multiple market segments, from luxury minis to bulk family-size formats.

- Consumers often associate larger tubes with better value—especially in mass-market skincare.

- Smaller tubes, though more expensive per ml, create an illusion of exclusivity and premium positioning.

- Shelf-space optimization also comes into play; retailers prefer diverse packaging size options that align with their display strategies.

💡 A quick tip: Match your tube size not only to product usage but also consumer lifestyle habits—urban commuters want compact; families prefer quantity.

When it comes to choosing between small and large custom cosmetic tube designs, it’s not about one being better—it’s about what fits your customer’s life best. From a business angle, offering both gives you a broader reach across demographics and price points without tweaking the formula inside.

Short tubes = agility + premium feel; long tubes = practicality + perceived value. Smart brands offer both and let the shopper decide based on need and vibe.

Here’s how various industries use different sizes:

| Industry | Common Tube Length | Typical Capacity | Use Case |

|---|---|---|---|

| Skincare | 100–150mm | 30–75ml | Serums & moisturizers |

| Haircare | 160–200mm | 100–250ml | Conditioners & masks |

| Travel Kits | ≤80mm | 5–15ml | Portable essentials |

| Pharmaceutical | Varies | 10–50ml | Ointments & gels |

This flexibility is what makes a tailored custom cosmetic tube strategy so powerful—it adapts packaging to suit real-world routines while keeping brand identity intact.

Customization as a Competitive Advantage in Branding

Let’s be real—on crowded shelves, no one’s got time to read every label. That’s where killer packaging steps up as your silent salesperson. Customizing your cosmetic tube packaging gives you an edge that goes beyond aesthetics:

• Stronger brand identity through consistent color palettes, fonts, and tactile finishes like matte or soft-touch coating. • Clearer market differentiation, especially when competitors stick with stock designs. • Better emotional connection via storytelling elements embedded right into the design—think embossed logos or custom cap shapes that reflect brand values. • Boosted shelf appeal thanks to unique forms that catch eyes faster than standard templates ever could. • Reinforced trust through quality cues like metallic foils or eco-labels printed directly on the tube surface.

Now let’s break it down step-by-step:

Step 1: Choose materials that reflect your message—eco-friendly? Go sugarcane-based PE or PCR blends. Premium? Try aluminum laminate with gloss varnish accents.

Step 2: Design graphics that speak instantly—minimalist black-and-white screams clinical chic; pastel gradients whisper “gentle care.”

Step 3: Pick closure types aligned with user experience goals—flip-top caps for ease of use or screw caps for secure sealing during travel.

Step 4: Align all these elements under a single visual language so consumers can spot you from across the aisle—or scroll screen!

When done right, custom packaging becomes part of your unique selling proposition, making it harder for copycats to mimic what makes you… well, you.

Here are three quick-fire reasons why this matters now more than ever:

- Gen Z shoppers rate aesthetic appeal nearly as high as product performance.

- Retail buyers favor brands with standout presentation—they know good looks drive impulse buys.

- According to Mintel’s Q2 Beauty Packaging Trends Report (2024), “Packaging personalization is now directly linked to increased consumer loyalty”.

So yeah—a thoughtfully designed custom cosmetic tube isn’t just pretty plastic… it’s straight-up business strategy wrapped in style.

Sustainability in Custom Cosmetic Tube Manufacturing

As eco-conscious beauty trends rise, brands must rethink how they make and design every custom cosmetic tube.

The Shift towards Eco-Friendly Materials: A Necessity

-

Eco-friendly materials like bio-based plastics are no longer niche—they’re expected.

-

Brands now experiment with:

- Recycled content, especially high-grade PCR materials

- Compostable films that mimic traditional tubes

- Hybrid packaging using both virgin and recycled resins

-

Consumer pull is strong—most shoppers actively seek out products in sustainable packaging

-

Material innovation isn’t just about being green; it’s about staying relevant

-

Companies like Topfeelpack have responded by integrating more green alternatives into their production lines without compromising aesthetics or durability

Reducing Carbon Footprint with Sustainable Practices

Energy efficiency isn’t just a buzzword anymore—it’s baked into smart manufacturing:

• Factories are switching to renewable energy sources like solar or hydro to power machinery used in molding each part of a cosmetic tube

• Many brands now track emissions across the full supply chain, investing in tools that support real-time monitoring for better carbon footprint reduction

• Process tweaks such as low-temperature extrusion reduce energy demand while maintaining quality finishes on custom tubes

Sustainable manufacturing has become a practical route, not just an ethical one—especially when paired with smarter logistics and localized sourcing.

Innovative Recycling Practices for Custom Tubes

♻️ The recycling game is evolving fast—and so is how we handle used beauty packaging:

- Some producers have launched take-back programs that feed directly into their own facilities, creating true closed-loop systems

- Newer reprocessing technologies separate laminate layers without degrading the tube’s integrity, making more of the material viable for reuse

- Embracing the principles of a circular economy, many brands now use only mono-material tubes to simplify sorting during disposal

These efforts help reduce waste while also supporting brand transparency—a win-win when it comes to modern eco expectations.

Designing for Sustainability: What to Consider in Production

Designing your next batch of tubes? There’s more than color palettes and caps to think about:

- Start with smart material selection—opt for lightweight plastics or bio-resins

- Incorporate features that boost reusability, like twist-open heads instead of single-use seals

- Apply strong eco-design principles, ensuring every element from ink to closure aligns with recyclability standards

- Use lifecycle assessment tools early on; they flag issues before tooling even begins

- Prioritize formats that allow easy separation during end-of-life sorting—think minimal glue, fewer mixed materials

Every detail counts when building sustainable value into your custom cosmetic tube line from day one.

FAQs about Custom Cosmetic Tube

1. How do LDPE and HDPE plastics feel in daily use?

The contrast is tangible:

- LDPE plastic bends softly in your hand, perfect for gentle squeezes of creams or gels.

- HDPE plastic holds firm—ideal when the formula must be stable during long journeys.

Choosing between them is like picking a favorite pen; one flows with ease, the other feels precise and steady.

2. What makes aluminum laminate tubes so valued for beauty products?

There’s quiet security in knowing what’s inside stays pure: Aluminum laminate provides a light but strong shell that shuts out oxygen and moisture without adding bulk—so your lipstick base or tinted balm reaches customers as fresh as the day it was made.

3. Which tube diameters work best for specific product textures?

Think of diameter as controlling rhythm in dispensing:

| Product Type | Suggested Diameter |

|---|---|

| Serum focus | 19mm diameter tubes / 22mm diameter tubes |

| Everyday cream jars replaced by tubes | 30mm / 35mm |

| Professional-size skincare kits | 50mm |

A narrow tip offers precision; broader lines deliver swift coverage on busy mornings.

4. How does cap style shift the user’s experience?

Every twist or snap tells part of your brand’s story:

- Flip top cap — quick single-hand access, handy mid-routine with wet fingers.

- Screw on cap — secure seal that builds trust during shipping overseas.

- Nozzle cap — focused flow for liquid formulas.

An acrylic cap can also act like jewelry atop your tube—shiny, clear, alluring.

5. Which printing methods bring personality to custom cosmetic tube designs?

Your logo isn’t just printed—it speaks from the shelf:

Offset printing gives sharp consistency across hundreds of units; silk screen brings raised texture under fingertips; hot stamping burns gold or silver into memory; digital printing allows small runs bursting with colorful gradients; label application adds layered dimension without redesigning entire packaging runs.

6. Why are eco-friendly materials gaining ground with large cosmetic orders?

Eco choices tell shoppers you care before they even unscrew the lid:

- PCR material shapes give second life to plastics already lived once.

- Sugarcane PE carries whispers of fields instead of fossil fuels.

Both keep their form whether crafted into glossy finish or matte finish designs—and resonate deeply with buyers who match skincare rituals to conscious living values alike.

References

- Packaging | Ipsos – ipsos.com

- Smithers research charts transition for offset to digital print – smithers.com

- The Future of Beauty Packaging: Here’s What Brands Need to Know | Mintel – mintel.com

- Difference Between HDPE and LDPE – Laiyang Packaging – laiyangpackaging.com

- What are the benefits of using aluminum tubes for cosmetics? – APG Packaging – apackaginggroup.com

- Sugarcane PE Tubes: The Future of Cosmetic Packaging – Product Info – Webpackaging – webpackaging.com

- What is Post Consumer Resin (PCR) Plastic? PCR’s Pros & Cons for Packaging – tricorbraun.com