What’s the Best Cosmetic Tube Printing Method for Your Product?

Your packaging is talking behind your back. No, really—before anyone even twists the cap, your custom cosmetic packaging is whispering sweet nothings (or loud nothings) into the customer’s ear. Is it saying “luxury,” “eco-chic,” or just…“meh”? In a market where shelf appeal can make or break you in three seconds flat, every pixel and finish counts.

Some brands spend a fortune on formulas but skimp on packaging choices that actually touch the buyer first. That’s like showing up to prom in flip-flops with your tux still at the dry cleaners. Don’t be that brand.

“Offset printing gives cleaner lines than my eyeliner,” laughs Mia Zhang, senior designer at Topfeelpack. “But if you’re pushing small-batch seasonal runs? Digital’s your ride-or-die.” Not all methods play nice with bio-plastics or aluminum either—and don’t even get us started on hot stamping drama.

So if you’re stuck between silkscreen dreams and foil-stamped fantasies, buckle up—we’re about to break down which method actually fits your product without torching your budget or dulling your visual vibe.

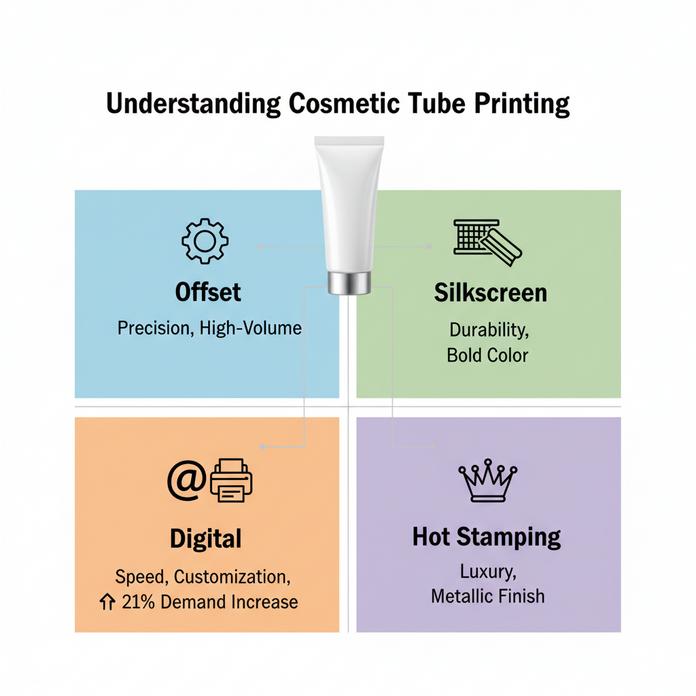

Understanding Offset Printing for Cosmetic Tubes

From sharp detail to consistent color, offset printing is a go-to for brands that want their cosmetic tubes to pop with precision. Here’s how it holds up across different formats.

Understanding Offset Printing for Cosmetic Tubes

- Offset printing uses printing plates and CMYK color layers.

- Best suited for high-volume runs due to its cost-effective setup.

- Perfect for designs needing crisp lines and smooth gradients on HDPE plastic tubes.

The whole process relies on transferring ink from a plate to a rubber blanket, then onto the tube surface. The result? Clean, repeatable prints with minimal distortion—ideal for brands scaling production without compromising quality. This method nails down consistency, especially when running thousands of units in one go. That’s why most premium skincare or haircare products opt for this technique when they need their branding locked in tight.

The Advantages of Silkscreen Printing Services

Silkscreen brings more than just durability—it adds texture and vibrancy that can’t be ignored.

Grouped by benefits:

-

Durability & Resistance

- Uses UV ink, which resists smudging and fading.

- Holds up against water, oils, and sunlight.

-

Visual Impact

- Creates bold, opaque colors, even over dark substrates.

- Offers a thick ink deposit for a tactile finish—great on squeezable tubes like those made from LDPE plastic.

-

Versatility

- Compatible with most plastics and even metallic surfaces.

- Works well on curved surfaces like round cosmetic tubes or ovals.

When your brand identity depends on bold logos or statement typography that literally stands out—you’ll want silkscreen every time. It’s not just about looking good; it’s about staying visible after weeks of use.

Exploring Digital Printing Techniques for Tubes

Digital’s here when you need speed without sacrificing flair. No plates mean no waiting around—just upload your file and go!

Here’s how digital printing fits the bill:

- Fast turnarounds—ideal for prototyping new product lines or seasonal limited editions.

- Supports variable data printing: personalize every tube with names or batch codes easily.

- Eco-conscious? Most digital methods pair well with biodegradable substrates like bio-plastics.

For indie beauty startups or agile skincare brands testing new SKUs monthly, digital is gold. One packaging supplier noted in their Q2 2024 report that “digital print demand increased by over 21%, driven largely by customization trends among Gen Z consumers”. That says everything about where this format is headed in modern cosmetic tube printing workflows.

When to Choose Hot Stamping Services

Hot stamping isn’t just glam—it’s strategic branding at its shiniest.

Grouped advantages:

-

Luxury Appeal

- Adds metallic elements like gold foil or holographic finishes using heat + pressure.

- Elevates perceived value instantly—especially effective on premium serums or anti-aging creams sold in sleek aluminum laminate tubes.

-

Tactile Branding

- Allows subtle embossing/debossing effects alongside foil application.

- Adds dimension without affecting usability of the tube itself.

-

Security Features

- Can integrate tamper-evident seals using specialized foils—a bonus layer of consumer trust built right into the pack design.

Hot stamping works best when you’re targeting upscale buyers who expect packaging to match product performance—and price tag. Think boutique shelf presence meets Instagram-worthy aesthetics.

Scientific Comparison Table: Print Methods vs Tube Materials

| Print Method | Material Compatibility | Setup Time | Customization Flexibility |

|---|---|---|---|

| Offset Printing | HDPE, PE | Medium | Low |

| Silkscreen Printing | LDPE, PP | Long | Medium |

| Digital Printing | Bio-plastics, PET | Short | High |

| Hot Stamping | Aluminum laminate, ABS | Medium | Low |

This table shows how each method pairs differently depending on material type and branding needs within cosmetic tube printing projects—from mass-market sunscreen tubes to niche organic balms packed in eco-containers.

Quick Recap: Choosing Your Ideal Cosmetic Tube Print Method

Short bites:

• Want crisp detail + bulk savings? Go with offset. • Need bold color + tactile feel? Silkscreen’s your jam. • Testing new SKUs fast? Digital wins hands down. • Looking luxe? Nothing beats hot stamping shine!

Each method has its moment depending on your tube size, material choice, and target market vibe. And remember—the right print makes all the difference between shelf filler and shelf stealer in today’s crowded beauty aisles!

4 Essential Techniques for Effective Cosmetic Tube Printing

Want your cosmetic tubes to turn heads? These techniques will give your packaging that extra punch without compromising function or feel.

Tips for Achieving a Glossy Finish on Cosmetic Tubes

A high-gloss finish can make even the simplest cosmetic tube printing design pop. Here’s how to get that shine just right:

- Use UV coating to boost surface reflectivity and durability.

- Apply a clear lacquer layer post-printing to intensify color depth.

- Opt for high-quality overprint varnishes designed specifically for plastic substrates.

- Choose co-extruded plastic tubes, especially 35mm diameter ones, which respond well to glossy treatments.

- Calibrate drying temperatures carefully—too much heat dulls the final finish, while too little causes smudging.

- Select inks compatible with high-gloss systems to avoid flaking or uneven surfaces.

These steps ensure your printed tubes don’t just look good—they gleam like they mean it.

The Role of Soft Touch Coatings in Premium Packaging

Soft touch isn’t just about looks—it’s about feel. That velvety texture? It says quality before someone even reads the label.

- Start by selecting a matte base layer; this sets up the tactile contrast needed for that plush effect.

- Overlay it with a specialized soft touch coating, which contains rubberized particles that create the signature smooth texture.

- For hand creams in 100ml capacity tubes, this combo adds both grip and elegance—two things consumers subconsciously crave.

- Brands aiming for premium appeal use soft touch because it signals luxury without shouting it—just like whispering confidence through packaging.

- Pairing soft touch with minimalist typography amplifies its impact, making every squeeze feel like an indulgence.

Mixing visual subtlety and physical richness is what makes soft-touch finishes such power players in premium skincare branding.

Achieving Eye-Catching Designs with Varnish Coating Options

When you’re working on narrow formats like 19mm sunscreen tubes, you’ve got one shot to grab attention—and smart use of varnish coatings can do just that:

- Combine spot UV varnish with matte backgrounds for intense contrast and focal points.

- Use gloss varnish selectively over logos or icons to highlight brand elements subtly but effectively.

- Play with textured effects by layering different types of varnishes—think ripple, sandblast, or silk finishes—for added dimension.

- Match coating choice with product tone; bold flavors pair well with shiny accents, while natural lines benefit from muted matte layers.

In tight spaces where design real estate is limited, strategic varnishing becomes your secret weapon in cosmetic tube printing success.

And when you want all these techniques executed flawlessly? Topfeelpack knows exactly how to bring your vision into sharp focus—down to every last millimeter of shine or softness.

Can Cosmetic Tube Printing Enhance Your Branding?

Cosmetic tube printing isn’t just decoration—it’s your brand’s handshake with the customer.

The Effect of Tube Material on Branding Perception

Choosing the right tube material can seriously shape how customers feel about your product and what they think your brand stands for.

- Plastic tubes are lightweight and cost-effective, but can sometimes feel less premium.

- Aluminum tubes give off a sleek, high-end vibe—great for luxury skincare lines.

- PCR material adds eco-value instantly, appealing to conscious shoppers who want sustainability without sacrificing style.

- Sustainable Cosmetic Packaging like sugarcane bio-plastics signals responsibility and innovation all at once.

- A richer tactile experience, such as soft-touch coatings or matte finishes, enhances perceived quality and encourages repeat purchases.

- For products like a 50ml eye cream, premium-feel packaging communicates effectiveness before the cap even comes off.

- According to Mintel’s 2024 Global Packaging Trends report, “Consumers increasingly associate packaging texture and weight with trustworthiness and efficacy”.

- The overall brand perception hinges not just on visuals but also on how the tube feels in hand—cheap plastic can undercut even the best design.

Topfeelpack taps into this by offering customizable materials that align with both eco-goals and aesthetic standards.

Leveraging Color Choices in Cosmetic Tube Printing

Color isn’t just pretty—it’s persuasion. And when it comes to cosmetic tube printing, smart color choices do more than pop; they communicate identity fast.

• Start by understanding color psychology: pinks suggest softness; deep blues signal trust; black screams luxe. • Match tones to your audience—Gen Z loves bold neons while millennials might lean toward muted earth tones. • Use consistent hues across product lines to build strong brand identity—think Glossier’s millennial pink or Fenty Beauty’s rich neutrals. • Ensure colors match across batches using precise tools like Pantone colors, avoiding awkward shifts that scream inconsistency. • Choose print methods wisely: digital CMYK is flexible for small runs; offset gives crisp lines for big orders. Both affect how ink interacts with the base material.

Now break it down further:

- Glossy vs matte finishes change how colors reflect light—gloss pops, matte soothes.

- Ink type matters too—UV ink resists fading better under sunlight exposure.

- For 15ml lip gloss tube especially, vibrant shades grab attention fast on shelves cluttered with similar shapes.

Ultimately, great cosmetic tube printing combines killer design instincts with technical know-how—and when done right, it makes people remember you before they even try what’s inside.

Digital vs. Traditional Cosmetic Tube Printing: Pros and Cons

Choosing between digital, offset, or silkscreen methods? Here’s how cosmetic tube printing options stack up—by size, style, and sustainability.

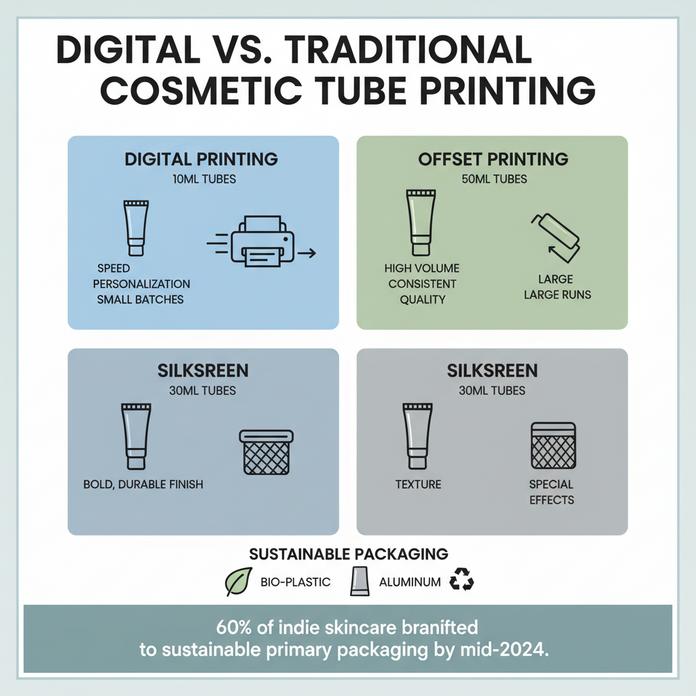

Digital Printing: Advantages for Short Runs of 10ml Capacity Tubes

• Small batches? Digital printing makes it easy to test new acne products without breaking the bank. • Need to swap out ingredients or branding fast? This method lets you update designs on the fly with variable data. • Personalization is key—names, shades, even QR codes can be printed directly on 10ml tubes, perfect for influencer collabs.

- Turnaround is lightning-fast—ideal when you’re launching limited-edition skincare lines.

- No need for plates = lower setup costs compared to traditional methods.

★ Best part? You only print what you need—zero waste vibes all the way.

Pros and Cons of Traditional Offset Printing for 50ml Tubes

| Feature | Benefit | Drawback | Ideal Use Case |

|---|---|---|---|

| Print quality | Sharp details on large surfaces | Less flexible with changes | Long-term product lines |

| Cost efficiency | Great per-unit price at high volumes | High initial setup cost | Mass production |

| Color consistency | Exact color matching across batches | Slow turnaround | Premium cosmetic packaging |

| Lead time | Predictable timelines | Not great for rush jobs | Seasonal campaigns |

Traditional offset printing works best when you’re scaling up your 50ml skincare line—and you’ve got time on your side.

Silkscreen vs. Digital: Quality in 30ml Capacity Cosmetic Tubes

- Silkscreen gives a bold pop—think rich colors and that raised ink feel that screams luxury.

- On the flip side, digital printing nails those intricate gradients and tiny text labels.

- For sunscreen creams in 30ml tubes, durability matters; silkscreen’s tactile finish holds up well under beach bag abuse.

- But if your design changes often (like SPF claims or ingredient tweaks), digital’s flexibility wins hands-down.

Quick tip: If your brand leans minimalist but sharp, go digital; if it’s all about bold visuals, silkscreen might be your jam.

Comparing Eco-Friendly Bio-plastic vs. Aluminum Laminate Tubes

“By mid-2024, over 60% of indie skincare brands shifted toward sustainable primary packaging,” notes Global Packaging Insights.

• Want to go green without losing functionality? Choose between:

→ Bio-plastic tubes

- Made from renewable sources

- Fully compostable options available

- Lighter carbon footprint

→ Aluminum laminate tubes

- Excellent barrier protection (ideal for eye creams)

- Recyclable but energy-intensive

- Feels premium in hand

Each has trade-offs—but both beat traditional plastic by miles in today’s eco-conscious market.

The Best Cap Types for Each Printing Method: A Quick Guide

Grouped by print style:

■ For offset printing, go with: – Flip-top caps (great alignment) – Screw caps (classic look)

■ For digital printing, try: – Nozzle tip caps (precise application + easy customization) – Airless pump caps (techy vibe pairs well with modern graphics)

■ With silkscreen printing, match with: – Metalized screw caps (adds luxury appeal) – Disc top caps (complements vibrant ink layers)

Picking the right cap isn’t just about function—it completes the whole visual story of your cosmetic tube design.

Struggling with Packaging Design? Try Customized Tube Printing

Personalized packaging isn’t just for show—it’s how brands tell their story. Let’s talk tubes, textures, and standout design.

Customized Tube Solutions for Hand Cream Packaging

• Material versatility: Choose between HDPE, LDPE, or layered laminate to balance flexibility with durability. Each has its own vibe—HDPE keeps it firm, LDPE offers that soft squeeze.

• Cap customization: Flip-top, screw-on, or metallic caps can totally change the feel of your product. Even the weight of the cap makes a difference.

• Printing techniques: Use offset or silkscreen to highlight your brand identity. Want to go bolder? Hot stamping adds that shiny pop.

• Tube shape options: Oval vs round—each one speaks differently on shelves and affects how customers handle them.

• Finish matters:

- Glossy finish = sleek and modern

- Matte finish = minimalist and premium

- Soft-touch = luxury all the way

These choices impact more than just looks—they influence how customers perceive your hand cream‘s quality before they even try it.

Unique Designs for Lip Gloss Packaging: Explore Your Options

🟢 Compact styles are king when it comes to lip gloss—but don’t stop at size. Think about applicator types like doe-foot wands or brush tips; they shape user experience big time.

🟢 Go bold with color-matched tubes using silkscreen printing for vibrant graphics that won’t rub off after two uses.

🟢 A little sparkle never hurt anyone—metallic foils or gradient effects elevate shelf appeal fast.

🟢 Material innovation is trending too. Lightweight multi-layered plastics keep things eco-friendlier without sacrificing style.

🟢 Branding? It’s not just about logos anymore. Embossed patterns or transparent windows let your formula shine through—literally.

When you’re designing for lip gloss packaging, it’s not just about holding product—it’s about holding attention too.

Enhancing Your Acne Treatment Packaging with Tailored Tube Designs

There’s more pressure on medical-looking products to appear trustworthy—and safe. That’s why every detail counts when building custom designs for acne treatments:

1️⃣ Barrier protection is non-negotiable: Use aluminum-lined layers inside plastic tubes to prevent contamination and extend shelf life.

2️⃣ Small-diameter nozzles help control dosage perfectly, especially critical for spot treatments.

3️⃣ Clean aesthetics matter—a white base color combined with minimalistic fonts communicates clinical confidence.

4️⃣ Tamper-evident seals add peace of mind while reinforcing product integrity.

5️⃣ Digitally printed batch codes make traceability easy and compliant with pharma standards.

6️⃣ Materials like LDPE plastic tubes offer both softness and chemical resistance—a must-have combo for sensitive skin products.

7️⃣ According to Mintel’s Q2 Skincare Report from March 2024, “Consumers trust packaging that looks sterile yet elegant.”

That blend of functionality + aesthetic might be the edge your acne treatment needs on crowded pharmacy shelves.

Comparative Table – Material & Print Options Across Cosmetic Tubes

| Tube Type | Common Material | Best Print Method | Ideal For |

|---|---|---|---|

| Hand Cream | HDPE | Offset / Silkscreen | Medium-viscosity creams |

| Lip Gloss | Multi-layer PE | Silkscreen / Foil | Color cosmetics |

| Acne Treatment | LDPE | Digital / Flexo | Medicinal gels |

| Sunscreens | Co-extruded PE | Flexographic | UV-sensitive formulas |

This breakdown helps simplify decisions during early-stage development by showing which formats suit each formula best during the cosmetic tube printing process.

Short Segments — What Makes Custom Tubes Stand Out?

- Texture tells a story before words do.

- Cap choice isn’t minor—it defines usability.

- Transparent zones show off color-rich formulas.

- Graphics should match tone—fun vs clinical vs luxe.

- The right nozzle changes everything for application control.

- Don’t forget tactile finishes—they’re what fingers remember most!

Even small tweaks during production can turn basic into iconic when done right with thoughtful tube printing strategies across cosmetic lines.

Why Material Matters More Than You Think

Different materials don’t just affect squeezability—they influence sustainability, print fidelity, and consumer trust:

Take LDPE—it bends easily but holds up well under pressure, ideal for medical-grade products like acne gels where precision matters most. HDPE holds its shape better but may crack under stress if mishandled long-term; still perfect for thicker creams needing strong barrier properties. And co-extruded multilayer plastics? They’re taking over thanks to their ability to combine strength + recyclability without compromising on print clarity during high-speed runs of cosmetic tube printing jobs.

So yeah… material ain’t just material—it’s strategy baked into every squeeze of product that hits someone’s hand or face daily.

Digital Meets Design — How Custom Printing Elevates Branding

Cosmetic brands are going digital—not just online but directly onto their packaging:

✔ QR codes integrated into tube labels lead users straight to tutorials or ingredient info pages. ✔ Variable data printing lets you personalize batches by region or campaign theme without retooling entire lines. ✔ High-resolution digital prints mean even gradients and micro-textures look crisp AF—even on curved surfaces like flexible tubes!

All this tech isn’t fluff either—it builds deeper brand interaction while keeping packaging lean and responsive across changing trends within the cosmetic tube printing industry today.

FAQs about Cosmetic Tube Printing

1. What makes offset printing services reliable for large cosmetic tube batches?

Offset printing services deliver balanced color tones and consistency across extensive lots like 50ml HDPE plastic or co-extruded plastic tubes.

- Best for 35mm–50mm diameter formats demanding precision artwork.

- Lower unit cost brings value to full skincare ranges with screw on cap closures or flip top cap closures.

- Ideal for brands producing uniform hand cream packaging under tight deadlines.

2. How do silkscreen printing services enhance cosmetic packaging appearance?

A short descriptive branch line: Each stroke of silkscreen translates pigment vitality directly onto LDPE plastic surfaces, making graphics durable and rich in shade contrast.

• Creates tactile dimension with glossy finish options or matte finish options fitting eye cream packaging around 22mm–30mm diameters.

• Serves well for mid-size units such as 30ml capacity sunscreen cream packaging emphasizing premium depth.

3. Why choose digital printing services for quick-turn sample runs?

Digital versatility allows SKU-specific graphics without heavy setup—perfect when experimenting with limited designs in eco-friendly bio-plastic tubes.

| Tube Capacity | Typical Diameter | Feature |

|---|---|---|

| 10ml capacity | 19mm diameter | > Personal detail adaptation |

| 15ml capacity | 22mm diameter | > Fast turnaround & fine accuracy |

- Supports vivid ink layering compatible with soft touch coating options, refreshing your trial acne treatment packaging lines immediately.

4. Can hot stamping services elevate the luxury tone of a brand’s presentation?

Hot stamping flashes metallic emotion across pearlized finish options and varnish coating options used in aluminum laminate constructions.

- Delivers shimmering accents often seen on high-end 100ml capacity hand cream packaging secured by oval cap closures;

- Suggests refined craftsmanship every time light hugs its golden texture—a subtle promise of elegance consumers feel instantly.

5. Which surface finish resonates most with premium skincare impressions?

Short bullet + summary combo:

✦ Glossy finish options reveal transparency that highlights logo beauty on sunscreen cream tubes (19–35mm).

✦ Matte or soft touch coatings lend gentle tactility perfect for lip gloss packaging using nozzle tip cap closures or disc top cap closures.

In conclusion, selecting finishes aligns emotional expectation—shiny confidence versus delicate calm—and completes each piece within true human sensibility toward modern cosmetic tube printing design aesthetics.

References

[1] Offset Printing vs. Digital Printing | Ink Tank – kaocollins.com

[2] Cosmetic Tube Printing: Methods, Techniques & Brand Impact – luxetubes.com

[3] What Is Hot Stamping? A Complete Guide for Cosmetic Brands – dalicapkg.com

[4] Mintel announces Global Consumer Trends for 2024 – mintel.com

[5] A Deep Analysis of Cosmetic Tubes: Materials, Designs, and Trends – lissonpackaging.com

[6] Digital Printing Packaging Market Analysis – skyquestt.com