Ultimate Guide to Selecting Empty Lip Balm Containers: Materials, Sizes & Designs

You’d be surprised how much drama a tiny tube can hold. From the twist-click of the mechanism to that satisfying snap of closure, empty lip balm containers carry more than balm—they cradle your brand’s personality in every swipe. And when you’re ordering by the thousands? Every detail matters like it’s center stage on Broadway.

The truth is, packaging isn’t just “the thing that holds stuff.” It affects price points, shipping weight, shelf appeal—and yes, even who picks it up first at checkout. As Lily Chen, Senior Packaging Engineer at Topfeel said in a 2024 supplier summit: “The container speaks before your product does.” That’s not just poetic—it’s sales math.

Choosing between aluminum and bamboo fiber feels kinda like choosing between sneakers or stilettos—depends where you’re going and who you want to impress.

So buckle up. We’re about to break down what makes size, shape, and materials worth their weight in bulk orders—because pretty only gets you so far without smart behind it.

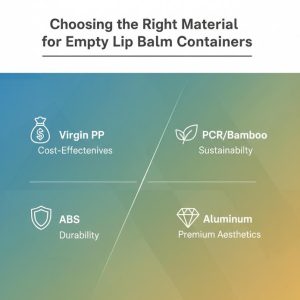

Choosing the Right Material for Empty Lip Balm Containers

When picking the best material for your empty lip balm containers, it’s all about balancing cost, sustainability, and style.

Virgin PP Plastic: The Budget-Friendly Option

- Affordable & accessible: Virgin PP is super wallet-friendly, perfect for mass production of plastic containers.

- Lightweight champ: It keeps shipping costs low without sacrificing function.

- Flexible design: Its moldability means you can get creative with shapes and finishes.

You’ll often see this material in bulk orders where keeping things cheap matters most. If you’re launching a starter line of lip care or testing the waters with new scents, this is your go-to.

Eco-Friendly PCR: Sustainable Choices for Conscious Brands

- ♻️ Made from post-consumer recycled plastic waste

- 🌱 Ideal for brands pushing environmental values

- 💪 Maintains durability close to virgin plastics

This option works well if you’re crafting eco-conscious branding around your lip balm packaging. PCR gives off that “we care” vibe while still holding up structurally like traditional materials. Plus, it helps cut down on landfill junk—win-win!

Recyclable Aluminum: Lightweight Yet Durable Solutions

Aluminum might cost more upfront, but its perks are hard to ignore:

| Feature | Benefit | Notes |

|---|---|---|

| Weight | Ultra-light | Easy to carry |

| Durability | Dent-resistant | Holds shape over time |

| Sustainability | Fully recyclable | No loss in quality when reused |

| Aesthetic appeal | Sleek, modern finish | Premium feel |

If you’re aiming to elevate your brand visually while also staying green, aluminum containers check all the boxes. These tins scream “classy” and last forever.

Durable ABS Resin vs. Sustainable Bamboo Fiber: Which is Best for You?

Let’s break it down into two camps:

🧱 ABS resin

- Super tough and resilient

- Perfect for twist-up mechanisms

- Great color retention

🌾 Bamboo fiber

- Biodegradable and compostable

- Earthy texture adds natural charm

- Slightly less durable under pressure

Choosing between these two depends on what matters more—longevity or earth-friendliness? If you want a sturdy case that’ll survive being tossed in bags daily, go ABS. But if your brand leans into nature-first storytelling, bamboo fiber brings that narrative home.

Comparing Materials by Use Case

Here’s how different materials stack up depending on your goals:

• Want budget-friendly bulk? → Go with Virgin PP plastic

• Need eco credibility? → Choose PCR plastic or bamboo fiber

• Looking for premium aesthetics? → Try out recyclable aluminum tins • Prioritize strength and mechanics? → Bet on durable ABS resin

Each type has its sweet spot based on how you plan to use or sell those slick little tubes of balm.

Which Material Matches Your Brand Personality?

Some quick-fire matches based on brand vibes:

🏷️ Minimalist skincare line → Aluminum tins with matte finish

🌿 Zero-waste indie shop → Bamboo fiber tubes with kraft labels

💼 Corporate giveaways → Budget-friendly virgin polypropylene cases

🌎 Socially conscious startup → PCR-based packaging with recycled branding tags

Your choice of container says just as much as what’s inside it—make sure it aligns with what you’re trying to say out loud through design.

Material Selection Checklist Before You Order

Before locking in your order of empty lip balm containers:

1️⃣ What’s your budget per unit?

2️⃣ Do you need sustainable certification?

3️⃣ Will the material hold up during shipping?

4️⃣ Does it match your visual branding?

5️⃣ How important is recyclability or biodegradability?

Ticking off these boxes helps avoid regrets later—and ensures every tube feels intentional from cap to base.

Final Thoughts: Blending Functionality With Feel

Every type of material—from sleek metal tins to earthy bamboo wraps—brings something unique to the table when designing empty lip balm containers. Some win at price points; others shine in sustainability or user experience. The trick isn’t finding the “best” one—it’s choosing what fits best with who you are and who you’re selling to.

Why Size Matters When Selecting Lip Balm Containers

Tiny tubes or hefty pots? When it comes to empty lip balm containers, size really does change the game—how much you carry, how often you refill, and how easy it is to toss in your pocket.

The Importance of Volume: 5ml vs. 10ml Containers

Choosing between a 5ml or a 10ml container isn’t just about space—it’s about lifestyle, habits, and even budget:

- Usage duration: A 5ml balm might last a few weeks with light use, while a 10ml one can stretch for months if you’re not slathering it on every hour.

- Refill frequency: Smaller sizes mean more frequent refills—great for switching flavors often, but annoying if you’re loyal to one blend.

- Cost efficiency: Larger volumes usually offer better value per gram. Bulk buyers or DIYers making their own blends will appreciate this.

- Portability trade-offs: While the bigger size lasts longer, the smaller one slips into jeans without bulging.

- Product quantity control: If you’re testing out new formulations in your homemade balms, starting with a compact volume helps minimize waste.

For those filling up batches of DIY lip care products using various types of lip balm tubes, knowing your volume sweet spot helps streamline production and storage.

Compact vs. Standard Sizes: Factors Affecting User Experience

The way we interact with our daily essentials matters more than you’d think—and when it comes to picking between a compact or standard-size tube for your balm, it’s all in the details:

• Smaller containers are more discreet—ideal for minimalist carry setups like clutch purses or slim wallets.

• Larger tubes tend to have better grip ergonomics; easier to twist open with cold fingers or apply on-the-go without dropping them.

• Reapplying from a tiny pot every couple hours gets old fast—standard sizes reduce that hassle significantly.

According to Mintel’s Personal Care Packaging Report (2024), over 60% of consumers cited “ease of use” as their top priority when choosing cosmetic packaging—including lip balms.

Whether you’re stashing them in your car cupholder or tossing them into gym bags, balancing form factor with function makes all the difference when selecting among different types of lip balm packaging options.

Travel-Friendly Dimensions: Ensuring Convenience and Accessibility

Jet-setters and daily commuters alike know that not all containers are created equal when it comes to travel readiness.

A small tube that meets airline regulations? Perfect for carry-ons. One that takes up zero real estate in your backpack side pocket? Even better.

Mini-sized jars under TSA limits aren’t just about compliance—they’re about ease-of-access when you’re dashing through terminals or hopping between meetings during business trips.

And let’s be honest—when you’re digging through your bag at 35,000 feet looking for something moisturizing, you’ll thank yourself for packing something sleek yet substantial enough not to get lost among cables and receipts.

That’s why people sourcing empty lip balm containers often favor those designed specifically with travel-friendliness in mind—not just by weight but by shape, cap security, and ease of application mid-flight.

From quick airport touch-ups to mountain hikes where space is gold, choosing smart dimensions ensures convenience doesn’t come at the cost of comfort.

Key Design Features to Look For in Lip Balm Containers

When picking the right packaging, design features can make or break how your empty lip balm containers perform—and look on shelves.

Closure Types: Comparing Snap-On Closures and Screw-Top Lids

• Snap-on lids are quick to open, perfect for on-the-go users. But they may pop off accidentally if tossed into a bag.

• Screw-top closures offer more security and help keep the balm fresher longer by locking out air. They’re ideal for premium or all-natural formulas that require tight sealing.

→ If you’re making a choice between these two types of closures, think about your customers’ habits—are they tossing this into a purse or using it at home?

Color Options: How Pantone Matched Colors Enhance Branding

- Pantone lets you match exact shades across product lines—no guessing games.

- It boosts brand recognition by keeping your color scheme consistent.

- Custom color matching means you can evoke emotions like calm (blue) or energy (red) with precision.

- When applied to empty lip balm containers, matched hues make even simple tubes pop with personality.

As of Q2 2024, NielsenIQ reports that color consistency increased shelf recognition by up to 34% for personal care brands.

Surface Finish: The Impact of Glossy Surface Coating vs. Matte Surface Texture

✦ A glossy finish screams high-shine glam—it reflects light and draws attention fast on retail displays.

✦ On the flip side, a matte texture gives off a modern, smooth feel—great for minimalist branding or eco-conscious vibes.

Both finishes affect how consumers perceive value and quality, so choose based on your brand’s tone and user expectations around touch and appearance.

Decoration Options: Boosting Aesthetic Appeal with Hot Stamping Foils

A sleek tube is nice—but add some shine with metallic accents? Now we’re talking style points.

Hot stamping uses pressure and heat to apply foil designs onto packaging surfaces like plastic tubes or caps. These foils can be gold, silver, holographic—you name it—and instantly elevate the perceived value of your product.

For many indie beauty startups using empty lip balm containers, this decorative method helps them compete visually with bigger names without breaking the bank.

Custom Shapes: Elevating Design with Unique Container Forms

Short stubby tubes? Overdone. Oval twist-ups? Unexpectedly chic.

■ Unique shapes give your product immediate shelf appeal—whether it’s geometric edges or ergonomic curves made for one-handed use.

■ They also reinforce branding through tactile memory; customers remember how something feels as much as how it looks.

Custom forms aren’t just about standing out—they help define what kind of experience users associate with your product line from first glance to final swipe.

Scientific Table Comparison – Performance Across Key Design Features

| Feature | Functionality Score (0–10) | Aesthetic Score (0–10) | Consumer Preference (%) |

|---|---|---|---|

| Snap-On Closure | 7 | 6 | 42 |

| Screw-Top Lid | 9 | 7 | 58 |

| Glossy Surface | 8 | 9 | 61 |

| Matte Texture | 7 | 8 | 39 |

This data shows screw-tops dominate when it comes to consumer trust in sealing power—a big deal when you’re storing natural balms prone to melting or drying out.

Natural Combination Structure Applied – Real Packaging Wins Start Here

Want real-world results? Then blend smart design decisions:

• Go bold with Pantone-matched colors on uniquely shaped tubes—that’s double the visual punch.

• Pair a matte finish with hot-stamped gold foil for contrast that oozes luxury.

• Choose screw-tops if you’re marketing organic balms that need airtight protection—but snap-ons still win for convenience-focused buyers.

• Don’t forget usability tests before finalizing packaging; even small tweaks like cap ridges can impact grip comfort during application.

From form factor to finish type, every tweak you make turns basic lip balm containers into branded experiences consumers love reaching for again and again—even after they’re empty.

Customizing Your Empty Lip Balm Containers: A Quick Guide

Personalizing your product packaging doesn’t have to be complicated—here’s how to make your empty lip balm containers pop with style and precision.

Color Your Way: Custom Tinted Pigments and Metallic Color Finishes

Customizing the look of your packaging starts with color—and trust us, it’s way more than just picking pink or gold.

• Want something bold? Go for high-gloss finishes that scream luxury while offering a protective layer on your plastic shell.

• Prefer subtle vibes? Matte tones using soft pastel tinted colors can create a minimalist, clean aesthetic.

• For something in-between, metallic sheens like rose gold or chrome silver give off that premium vibe without being too flashy.

But it’s not just about picking a shade off the shelf—you can work with manufacturers to match exact brand hues using precise color matching systems. This ensures every batch of your empty lip balm containers looks consistent on store shelves or in influencer flat-lays.

Designers often combine custom pigments with layered coatings to achieve multi-dimensional effects—like shimmer-infused purples or frosted teal tones—adding depth and uniqueness to every unit’s surface finish.

And when it comes down to consumer psychology, color plays a bigger role than most realize. Studies show packaging color influences purchasing decisions by up to 80%. So yeah, don’t sleep on this part of the process if you’re trying to stand out in an oversaturated market.

From Design to Production: Understanding the Injection Molding Technique

The magic behind those sleek little tubes? It all starts with something called injection molding—a process that combines art and science into one seamless flow.

Step 1: A mold is designed based on your desired tube shape, size, and internal mechanics like twist-up mechanisms or snap caps—this is where thoughtful product design kicks in big time.

Step 2: Once tooling is ready, molten plastic gets injected into these molds under high pressure using specialized equipment built specifically for high-volume runs—a cornerstone of modern-day plastic molding processes.

Step 3: After cooling down inside the mold cavity, each unit pops out fully formed and nearly ready to go—no trimming needed thanks to tight tolerances built into the system.

Step 4: These freshly molded pieces are then assembled if needed—some designs require separate base inserts or rollers—and prepped for finishing touches like printing logos or adding those custom tints we talked about earlier.

Thanks to this method’s efficiency and repeatability, brands can produce thousands—even millions—of identical empty lip balm containers without sacrificing quality control. That’s why most large-scale operations swear by injection molding—it balances cost-efficiency with creative freedom better than almost any other method out there today.

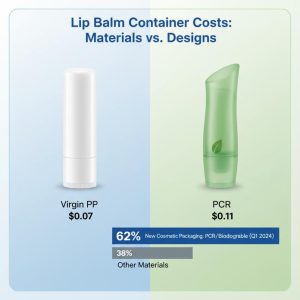

Evaluating Costs: Materials vs. Designs for Lip Balm

Quick reality check—when it comes to pricing out those empty lip balm containers, two things hit your wallet hardest: what they’re made of and how fancy they look. Let’s break both down.

Cost Breakdown: Analyzing Virgin PP Plastic vs. Eco-Friendly PCR

- Virgin PP plastic tends to be cheaper upfront but lacks the eco-punch that modern consumers are hunting for.

- PCR plastic, while pricier, scores points with sustainability-minded buyers and can boost perceived value.

- The price gap between the two materials is narrowing as demand for sustainable packaging grows.

💬 “In Q1 2024, over 62% of new cosmetic packaging launches used PCR or biodegradable blends,” according to Mintel Packaging Insights. That stat alone should make you think twice before defaulting to virgin materials.

| Material Type | Avg. Cost (per unit) | Environmental Impact | Consumer Preference Trend |

|---|---|---|---|

| Virgin PP | $0.07 | Low | Moderate |

| PCR (Post-consumer) | $0.11 | High | High |

| Bioplastics | $0.13 | Very High | Growing |

| Hybrid Mix | $0.10 | Medium | Rising |

Whether you’re sourcing plain tubes or custom-shaped empty lip balm containers, knowing your material costs can save you big time down the line.

Design Complexity: How Features Affect Overall Pricing

Design tweaks can be dealmakers—or budget busters:

- Custom molds = higher tooling expense

- Multi-color prints = bumped-up decoration techniques

- Irregular shapes = added molding costs

- Magnetic closures or slide mechanisms = more labor + parts

Each of these layers on top of your base cost per unit, especially when ordering small batches.

Want a sleek matte finish with laser etching? Expect that aesthetic glow to come with a price tag—every extra step adds complexity and hikes up manufacturing time too.

Balancing Budget and Aesthetics: Prioritizing Essential Design Elements

You don’t have to go full minimalist, but trimming non-essential frills helps:

• Stick with standard closure types unless function demands otherwise

• Go for single-color options instead of multi-layered coatings

• Focus on one standout design feature—like metallic caps or embossed logos—and skip the rest

Visual appeal matters, sure—but not at the cost of profitability when you’re scaling up production on thousands of lip balm container blanks.

Break it down like this:

- Must-have features? Keep ‘em.

- Nice-to-haves? Reconsider.

- Totally extra stuff? Ditch it unless you’re selling high-end product lines.

Smart choices here mean you’ll still turn heads without burning through your budget on every run of those shiny new empty lip balm containers.

FAQs

What materials suit bulk orders best for empty lip balm containers?

Virgin PP Plastic keeps costs down and resists daily wear.

Eco-Friendly PCR signals sustainability to modern buyers.

Recyclable Aluminum whispers luxury with a lasting shine that returns endlessly to the supply chain.

How do sizes shape purchasing decisions in wholesale cosmetic packaging?

Smaller 5ml units dance easily into compact displays alongside mascara containers or eyeliner pens, perfect for impulse buys.

Larger 10ml formats feel generous—like foundation bottles offering more time before replacement—and quietly boost perceived value over months of use.

Which closures protect products during long-distance shipping?

- Screw-Top Lids clamp tight against leaks on bumpy roads.

- Snap-On Closures quicken retail rotation without sacrificing seal strength in normal handling.

- Child-Resistant Caps stand guard where regulation demands tamper protection, keeping balm safe until intended hands open it.

How can surface finishes strengthen a brand’s identity through lip balm packaging?

Glossy Surface Coating catches light like lipstick tubes under boutique spotlights; Matte Surface Texture feels grounded, akin to soft-touch compacts cradled in the palm; Textured finishes invite fingertips back again, anchoring emotional memory to design choice.

Which customization tools help brands stand apart when selling wholesale lip balm products?

Pantone Matched Colors promise visual unity across product lines from mascara cases to bamboo fiber foundation bottles; Metallic Color Finishes spark exclusivity that Metallization Coatings deepen into rich sheens; Hot Stamping Foils etch names permanently while UV Varnishing Finishes lock ink brilliance for shelf endurance.

| Decoration | Effect | Best Use |

|---|---|---|

| Hot Stamping Foils | Shiny imprint | Luxury branding |

| Screen Printing Inks | Crisp logos | Everyday retail |

| Metallization Coatings | High-shine metal look | Premium stores |

Is injection molding still king for producing large runs of cosmetic makeup packaging like empty lip balm containers?

Yes—the Injection Molding Technique shapes screw mechanisms with crisp precision at remarkable speed, letting designers weave twist-up mechanisms or magnetic closures into ABS resin bodies without slowing mass output… every piece identical yet waiting for each buyer’s personal touch once filled and sold.

References

- Mintel Group Ltd. (2024). US Household Care Packaging Trends Market Report. Mintel Store – US Household Care Packaging Trends Report 2024

- Cosmetics Business. (2023). 6 Reasons Why Beauty Brands Are Choosing Aluminum Packaging. Cosmetics Business – Rise in Aluminium Packaging Trend

- BambooPackage. (2025). What are the key advantages of using bamboo for cosmetic packaging compared to traditional materials like plastic?. BambooPackage – Advantages of Bamboo vs Plastic

- NielsenIQ. (2024). Brand recognition. NielsenIQ – Brand Recognition Information

- Journal of Marketing and Sales Research. (2025). The Psychology of Color in Marketing. JMSR Online – Psychology of Color