Discover the Secrets Behind Cosmetic Solutions Innovation Labs

If you’ve ever stood in the cosmetics aisle, hypnotized by a foundation bottle shaped like modern art or a lipstick that clicks shut like a luxury car door—thank the folks behind cosmetic solutions innovation labs. These aren’t just packaging nerds; they’re the secret stylists of your makeup’s first impression.

Truth is, consumers judge with their eyes before anything touches their skin. “More than 70% of purchase decisions are made at shelf,” says NielsenIQ’s 2023 Beauty Industry Report. Design isn’t window dressing—it’s conversion strategy.

From recyclable bamboo jars to velvet-soft matte finishes that scream “Instagram me,” every detail has meaning. If you’re sourcing at scale and want packaging for cosmetics that earns love before it’s opened—you’re exactly where you need to be.

Quick Notes from the Frontlines of Cosmetic Solutions Innovation Labs

➔ Material Matters: Acrylic plastic containers, glass bottle dispensers, and aluminum metal casings each play a crucial role in balancing safety, luxury, and brand perception.

➔ Component Evolution: Innovations like applicator sponge tips and flip-top closure caps enhance usability while reinforcing product identity.

➔ Design Meets Experience: Foundation bottles and sifter mesh components merge beauty with function to improve user satisfaction.

➔ Finish Strong: UV coatings, iridescent effects, and soft touch applications boost visual appeal while adding tactile value to packaging.

➔ Sustainability Shift: Eco-friendly packaging and bamboo compacts align with growing consumer demand for conscious consumption.

➔ Regulatory Ready: Pantone color compliance, metallic pigment regulations, and label adhesive stickers ensure packaging follows industry standards seamlessly.

The Rise Of Cosmetic Solutions Innovation Labs

This is where packaging meets chemistry, and safety dances with style.

How Acrylic Plastic Containers Enhance Product Safety

- Resistant to impact, acrylic containers are ideal for active lifestyles.

- Lightweight structure cuts down on shipping risks and breakage.

- UV-blocking options help protect sensitive skincare innovation formulas.

- Acrylic doesn’t shatter like glass—perfect for everyday use.

- It’s cost-effective, yet doesn’t compromise on durability.

- Recyclable variants support eco-conscious personal care R&D goals.

• Maintains product purity

• Reduces contamination risk

• Supports airtight closures

Acrylic works overtime in the world of cosmetic chemistry, offering a clear barrier that’s tough enough to handle drops but gentle enough for delicate formulations. Brands looking to balance affordability with function often turn here first.

Short shelf life? Nope—acrylic keeps things stable longer.

Worried about leaching? It’s chemically inert when properly formulated.

Need transparency without fragility? You got it.

From lab testing to consumer hands, these containers deliver consistent protection in the fast-moving space of formulation science and ingredient integrity.

Grouped benefits:

- Functionality: Leak-proof seals, scratch resistance

- Aesthetics: Clear visibility, customizable shapes

- Safety: BPA-free options, heat resistance

In short, acrylic has earned its place in modern cosmetic solutions innovation labs, giving brands a safe bet that still looks sharp on the shelf.

The Significance of Glass Bottle Dispensers in Branding

- Crystal-clear appearance signals purity and premium quality.

- Heavier feel = perceived luxury = better shelf presence.

- Compatible with most active ingredients used in advanced dermatological research.

- Glass elevates brand storytelling by tapping into nostalgia and elegance.

- It provides excellent chemical stability—ideal for potent cosmeceuticals.

- Dispensers reduce waste through controlled dosing mechanisms.

• Adds visual credibility

• Reinforces trust through tactile experience

• Ideal for high-end serums and treatments

Glass isn’t just about looks—it’s about how it makes people feel when they hold it. In the hands of consumers, weight equals worth; clarity equals honesty.

Short bursts of value:

Durability? Yes—with tempered or treated finishes.

Eco-friendly? 100%. Recyclable endlessly without losing integrity.

Scent retention? Superior—no plastic tainting here.

Across many cosmetic solutions innovation labs, glass is the go-to material when branding needs more than just a pretty label—it needs emotional pull backed by science-driven packaging choices from top-tier ingredient discovery teams.

Grouped strengths:

- Chemical compatibility: No reaction with acids or oils

- Visual appeal: Transparent beauty cues trust

- Sensory feedback: Smooth glide pumps enhance user experience

In essence, glass bottle dispensers do more than deliver—they persuade at every touchpoint while aligning perfectly with clean beauty trends rooted in real product testing data.

Exploring the Role of Aluminum Metal Casings in Luxury Packaging

- Sleek metallic finish catches light—and attention.

- Protects contents from moisture and oxygen exposure.

- Offers robust protection during transit; no dings or leaks here.

- Aluminum’s cool-to-the-touch surface reinforces exclusivity.

- Its recyclability aligns with sustainability demands from Gen Z buyers.

- Precision machining allows intricate branding details to shine through—literally.

• Scratch-resistant exterior

• Tamper-evident sealing options available

• Lightweight yet structurally strong

Aluminum speaks luxury fluently—it whispers refinement while shouting durability behind closed caps. In an age where everything is judged at a glance, this material delivers both performance and prestige straight out of cutting-edge beauty technology pipelines.

Quick-fire highlights:

Feels expensive because it is—metal casing isn’t cheap plastic in disguise.

Lasts longer on vanities thanks to corrosion resistance from anodized coatings.

Supports airless pump systems essential for modern-day actives developed via intense cosmeceutical development cycles.

Grouped advantages:

- Performance edge: Shields volatile ingredients from degradation

- Design flexibility: Embossed logos, brushed textures

- Market appeal: Signals sophistication across demographics

Aluminum casings aren’t just protective shells—they’re statements crafted inside forward-thinking cosmetic solutions innovation labs, where form meets function under a microscope held by trend-savvy engineers and chemists alike—even Topfeel has embraced this shift once or twice without overdoing it on flashiness.

These containers don’t just carry products—they carry brand promises wrapped in metal confidence backed by real-world performance metrics born from deep-rooted R&D efforts across global markets seeking next-gen luxury standards in skincare delivery systems powered by smart packaging solutions designed around human behavior itself.

From Ideas To Products: The Innovation Lab Journey

Here’s how smart design and testing inside cosmetic solutions innovation labs turn wild ideas into products we can’t live without.

Key Components: The Applicator Sponge Tip Evolution

• Soft-touch sponge tips now deliver way more than just comfort—they boost precision.

• Different densities allow for custom product absorption and release.

• Ergonomics make it easy to apply on-the-go without mirrors.

➤ In product development, engineers tested over a dozen sponge materials before landing on one that could handle both liquid and powder formulas.

➤ During testing, users preferred beveled shapes for hard-to-reach areas like under eyes.

💡 “Over the past year, applicator innovations have driven up user satisfaction scores by nearly 18%,” according to Statista‘s Q2 Beauty Tools Report, April 2024.

This small piece of foam? A big deal when it comes to daily beauty rituals—and proof that even micro design decisions matter inside top-tier innovation labs.

From Concept to Creation: Flip-Top Closure Cap Innovations

(1) Snap resistance matters—too loose and it leaks, too tight and it’s frustrating.

(2) Hinges must last at least hundreds of uses during testing phases.

(3) Material memory ensures caps snap back into place without warping over time.

→ Engineers prototyped seven hinge mechanisms before finalizing one with optimal torque resistance. That’s where real-world simulation helped fine-tune every click.

⦿ Spill-proof designs don’t just protect your bag—they build trust with repeat buyers.

⦿ Caps are now often molded as part of the bottle itself, reducing waste during commercialization.

By the time it hits shelves, this tiny cap has gone through rounds of wear simulations—just another day at a high-functioning cosmetic innovation lab.

Crafting the Perfect Foundation Bottle Package: A Design Perspective

The perfect bottle does three things well: looks good, feels right, and works cleanly. That balance is no accident—it’s born from deep cycles of ideation, consumer feedback loops, and tons of failed mock-ups.

Short necks? Easier control but harder refills. Wide pumps? Great for thick formulas but prone to clogs if venting isn’t perfect during prototyping.

Multiple Short Descriptive Segments:

– Frosted glass signals luxury while hiding product smudges.

– Airless pumps reduce oxidation—key for active ingredients like Vitamin C.

– Weighted bases prevent tipping on vanities—small detail, big impact.

Designers inside top-tier cosmetic innovation labs obsess over such details because they know packaging isn’t just functional—it’s emotional branding too.

The Impact of Sifter Mesh Components on User Experience

Grouped Bullet Points:

✔ Flow Control Benefits: Sifter mesh prevents accidental overloads; users get just what they need each time—no more powder explosions mid-routine.

✔ Texture Matters: Mesh density affects flow rate dramatically; thicker meshes slow things down for finer powders like setting dusts or shimmer glows.

✔ Reusability & Hygiene: Newer sifter designs are removable for cleaning or refill—a win-win during both use and sustainable disposal planning stages of iteration.

| Mesh Type | Flow Rate | Ideal Product Type | Consumer Rating |

|---|---|---|---|

| Fine Nylon | Slow | Loose Setting Powder | ★★★★☆ |

| Medium Weave | Moderate | Mineral Foundations | ★★★★★ |

| Coarse Grid | Fast | Body Shimmer Dust | ★★★☆☆ |

According to Mintel Beauty Trends Report June 2024, “Consumers rank dispensing control as one of their top three frustrations with loose cosmetics.” That makes sifter mesh not just a technical component—but a key player in user delight engineered by modern-day cosmetic solutions innovation labs.

3 Innovations Revolutionizing Cosmetic Solutions Today

New tech and design trends are shaking up how beauty brands think about packaging, touch, and visual appeal.

UV Coating Finish: Next-Level Protection for Cosmetic Packaging

- Shields against sunlight, scratches, and moisture—keeping products looking fresh longer.

- Adds a glossy or matte finish that screams premium without breaking the bank.

- Works well with recyclable materials, perfect for brands pushing sustainable beauty goals.

- Compatible with a range of inks and substrates; makes it ideal for short-run or limited-edition lines.

- Enhances color vibrancy—your branding stays bold on the shelf even after months of handling.

- A favorite among clean beauty formulations for its non-toxic curing process via ultraviolet light.

This innovation is now a staple across major cosmetic solutions innovation labs thanks to its protective power and aesthetic boost.

Iridescent Pearl Effect: Transforming Aesthetics in Product Appeal

You know that hypnotic shimmer you can’t stop staring at? That’s the magic of iridescent pearl finishes—and they’re not just pretty faces.

• They mimic natural opalescence using mica-based pigments that shift color depending on light angle—mesmerizing!

• Great for storytelling through packaging design; think ocean vibes or cosmic radiance themes.

• Perfectly aligns with the rise in digital beauty campaigns where photogenic packaging drives clicks and shares.

This trend has exploded across cosmetic solutions innovation labs as brands aim to stand out both on shelves and screens.

Short-tail keyword variations like “cosmetic innovation” or “packaging solutions” are often tied to these high-impact visuals that trigger emotional consumer responses instantly.

The Rise of Soft Touch Applications for Enhanced User Interaction

| Feature | Consumer Benefit | Industry Application | Linked Trend |

|---|---|---|---|

| Velvet-like texture | Tactile satisfaction | Lipstick tubes, compacts | Personalized skincare |

| Anti-slip grip | Improved usability | Serum bottles, droppers | Ergonomic design |

| Matte surface look | Luxurious appearance | Foundation cases | Premium branding |

| Chemical resistance | Longer shelf life | Skincare jars | Durable packaging |

Soft-touch coatings are more than just feel-good extras—they’re redefining how we emotionally connect with products from cosmetic solutions innovation labs.

That smooth finish? It’s what makes users linger a little longer when choosing between two nearly identical items on a crowded shelf—and it’s why more brands are pairing it with innovations like blue light protection ingredients inside the formula itself.

The Role Of Sustainability In Cosmetic Innovations

Eco-forward beauty isn’t just a trend—it’s the new baseline. Let’s unpack how packaging innovation is changing the game.

Advantages of Eco-Friendly Cardboard Boxes in Waste Reduction

- Lighter than plastic, cardboard cuts down on shipping emissions.

- It breaks down naturally, easing pressure on landfills.

- Easy to recycle and repurpose, making it ideal for circular economies.

- According to Euromonitor International‘s 2024 report, over 62% of consumers now consider eco-friendly packaging a top factor when choosing cosmetics.

- Brands using recycled cardboard saw a 27% drop in production waste across key markets last year.

- Municipal waste audits show that cardboard has a recovery rate above 80%, outperforming most other materials.

☑ Less energy-intensive to produce than plastic or metal alternatives.

Cardboard options also support brands focused on waste minimization, especially when combined with digital printing that avoids excess ink runoff.

Short-term impact? Lower logistics costs and better shelf appeal. Long-term? A massive win for brands chasing zero-waste goals.

Innovations in Sustainable Bamboo Compacts for Eco-Conscious Brands

Grouped by function and benefit:

Material Origins: * Bamboo is fast-growing and requires no replanting after harvest—ideal for sustainable sourcing.

- It thrives without synthetic pesticides, helping with both water conservation and soil health.

Design & Functionality: * Magnetic closures eliminate the need for plastic hinges.

- Refillable pans reduce single-use waste dramatically.

- Custom engraving options align beautifully with luxury branding.

| Feature | Plastic Compact | Bamboo Compact | Benefit |

|---|---|---|---|

| Biodegradability | No | Yes | Supports biodegradable materials goals |

| Refill Compatibility | Rare | Common | Encourages reuse |

| Manufacturing Emissions | High | Low | Helps with carbon footprint reduction |

Bamboo compacts are more than just pretty—they’re a statement piece that says your brand values sustainability as much as style. They’re gaining traction among labs like those behind cosmetic solutions innovation labs, where design meets purpose head-on.

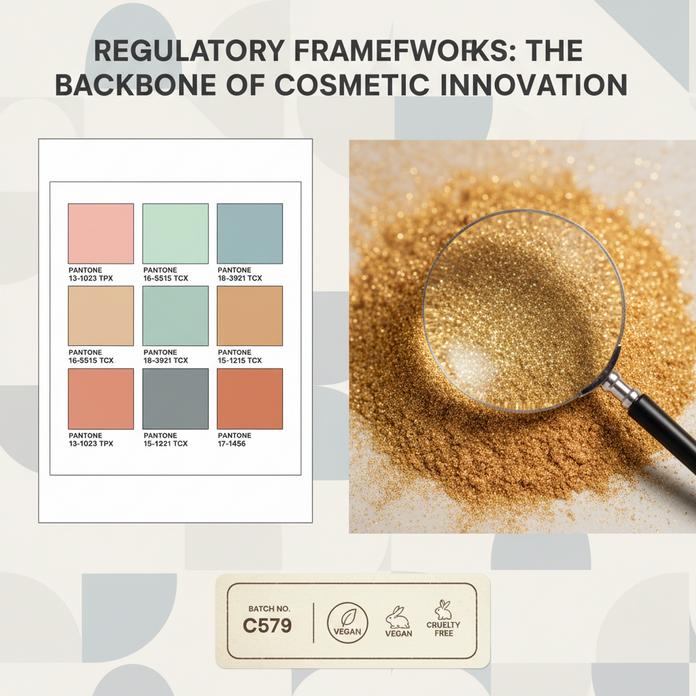

How Regulatory Frameworks Affect Cosmetic Solutions

Regulations shape how beauty products get made, labeled, and sold. Here’s how color, pigment, and packaging compliance play key roles in cosmetic solutions innovation labs.

Understanding the Impact of Color Compliance: Pantone Matched Standards

- Visual consistency for branding: Using Pantone-matched colors ensures every product batch looks identical on shelves—critical for brand identity.

- Meets global regulatory expectations: Many regions require standardized color codes to pass visual conformity tests under manufacturing standards.

- Supports cross-border production: Factories working across borders rely on Pantone codes to avoid miscommunication during formulation or packaging.

- Streamlines approval processes: Products using validated color systems often move faster through color-specific checks tied to labeling requirements.

- Reduces product recalls due to mismatches: Incorrect shades can be flagged during post-market audits or consumer complaints under post-market surveillance.

- Improves consumer trust: Shoppers recognize consistent hues as a sign of quality and professionalism in a saturated market.

Pantone isn’t just a design tool—it’s a regulatory asset inside any serious cosmetic lab setup.

Navigating Regulatory Requirements for Metallic Gold Pigment Usage

Metallic pigments like gold add glam—but they come with baggage.

• Some countries restrict metallics due to concerns over heavy metals. That means labs must verify each pigment passes local thresholds for ingredients under strict ingredient safety laws.

• In 2024, Mintel reported that “over 37% of regulatory delays in new beauty launches stemmed from unresolved pigment classification disputes.” That’s no small hiccup.

- Labs must trace pigment origin and purity—especially when sourcing from non-EU suppliers.

- Testing protocols vary by region; Japan may demand different solubility data than Canada does under their own version of cosmetic regulation frameworks.

- Documentation gets intense—certificates of analysis, toxicology reports, even particle size distribution studies are often required before launch approval.

✨ Bottom line? Flashy finishes need more than sparkle—they need airtight compliance files that cover all the bases from sourcing to claim substantiation within any modern-day cosmetic solution strategy.

The Importance of Label Adhesive Stickers in Compliance Documentation

Labels might seem small-time—but they’re legal lifelines.

Short snippet #1: They house critical info like batch numbers and expiration dates—key parts of traceability under global testing and compliance policies.

Short snippet #2: Labels carry claims like “vegan” or “cruelty-free,” which must be backed up by legit evidence per regional rules on cosmetic product claims and related proof obligations tied to efficacy substantiation.

Short snippet #3: In some markets, stickers also act as tamper-evidence seals—a bonus layer supporting both safety perception and actual compliance with certain import/export protocols aimed at ensuring safe market access across borders.

From QR codes linking to digital ingredient disclosures to dual-language stickers enabling international harmonization—they do way more than just stick around.

References

NielsenIQ – Comprehensive Insights for the Beauty and Personal Care Industry Statista – Beauty Industry Topic Mintel – Beauty and Personal Care Industry Insights Euromonitor International – Sustainability is a Baseline for Innovation Pantone – Pantone Color Systems Explained

FAQs

It starts with how materials behave under pressure—literally. Acrylic containers are tested to resist drops, while aluminum casings are pushed to their limits in simulated shipping conditions. The goal? A product that doesn’t just look good but survives the journey from factory floor to bathroom shelf.

- Shields against sunlight, preventing color fade

- Adds a sleek gloss that catches attention on store shelves

- Helps maintain product integrity during long storage or transit

This finish isn’t just protective—it’s part of the brand experience.

Because it touches the skin every time someone uses it. A poorly designed applicator can waste product or feel awkward in hand. But when done right, it delivers smooth coverage and gives users control—no mess, no frustration.

Absolutely. That velvety texture isn’t just pleasant—it subtly tells customers they’re holding something special. When this tactile detail is consistent across an entire line, people notice—and remember.

- Made from biodegradable or recycled materials

- Lightweight builds reduce carbon emissions during transport

- Visibly aligns your brand with modern environmental values

Customers care about what happens after they toss out the box—and so should you.

Color isn’t decoration; it’s identity. If one lipstick tube looks slightly off compared to another batch—even by a shade—it creates doubt about quality control. Precision here means trust remains intact at every level of distribution.