New Approaches to Wholesale Cosmetic Packaging in

Sourcing wholesale cosmetic packaging these days can feel like choosing the right outfit for a blind date—it’s got to look sharp, perform under pressure, and not fall apart halfway through the night. But here’s the kicker: with rising freight costs and customers side-eyeing anything that isn’t eco-friendly, beauty brands are stuck juggling looks, logistics, and landfill guilt. Sound familiar?

There’s a fresh wave of solutions bubbling up—think refillable compacts that snap shut like a dream or aluminum bottles that scream sleek without weighing down your shipping budget. Packaging isn’t just part of the product anymore…it is the product.

Reading Notes for Smarter Sourcing: Wholesale Cosmetic Packaging at a Glance

- Material Matters Most: PET plastic offers lightweight savings, while glass bottles bring premium appeal with UV protection—choose based on product positioning and freight goals.

- Design Drives Cost: Hot stamping adds elegance but costs more than UV coating; align decoration choices with budget constraints and branding strategy.

- Waste Not, Want Not: Refillable blush compacts and cardboard sleeves reduce environmental impact while keeping aesthetics sharp—sustainable doesn’t mean boring.

- Shipping Wisdom Wins: Lightweight cylindrical PET lipstick tubes and oval aluminum containers streamline international air freight, cutting costs without sacrificing style.

- Bulk Brings Benefits: Volume pricing tiers and pallet shipments offer serious cost reductions per unit—essential for scaling efficiently in global cosmetic markets.

Types Of Wholesale Cosmetic Packaging Materials

A quick guide to the most popular materials used in bulk beauty packaging and why each one has its moment in the spotlight.

PET plastic solutions for volume pricing tiers

- Lightweight build makes it ideal for shipping large quantities without spiking freight costs.

- High clarity allows vibrant product visibility, giving that clean shelf appeal.

- Recyclable nature meets growing eco-conscious demands among retailers.

- Compatible with various closures—flip tops, pumps, sprayers—boosting versatility.

- Customizable shapes and sizes help brands stand out while staying under budget.

- Tiered discounts kick in at higher volumes, making PET plastic a go-to for scaling up fast.

- Popular across skincare, haircare, and travel-size lines due to its balance of cost and performance.

How acrylic resin elevates mascara containers design

• Sleek finishes? Check. Glossy or matte? You got options with acrylic.

1) It’s tough as nails—resisting cracks even when tossed into makeup bags daily.

2) And it doesn’t just look good—it holds up under pressure, literally and figuratively.

→ Brands love how easy it is to color match acrylic components with their exact branding palette.

• Want translucent barrels or bold opaque tubes? Acrylic handles both like a pro.

There’s also something about the way this material reflects light—it adds a luxe touch that punches above its price point.

Plus, according to Mintel’s 2024 Beauty Packaging Report, “consumers increasingly associate weighty plastics like acrylic with premium quality,” which helps justify higher retail prices without changing the formula inside.

Bulk glass bottles with UV coating protection

Some things are just better in glass—especially when your product needs that luxury feel or airtight integrity:

Short bursts of why it’s winning:

– Feels heavy = feels expensive. Customers notice.

– UV coatings protect sensitive formulas from breaking down.

– Works wonders for serums or oils prone to oxidation.

– Offers embossing/engraving options for brand storytelling.

– Reusable by end-users = bonus sustainability points.

Even though it’s breakable, many brands still prefer it when they want their packaging to say “high-end” before customers even twist off the cap.

Aluminum containers: Durable and sleek foundation bottles

1) When durability is non-negotiable, aluminum delivers—it’s dent-resistant and leak-proof under pressure.

2) The cool-to-touch metallic finish gives off serious pro vibes on vanities or store shelves alike.

3) It’s fully recyclable without losing quality over multiple cycles—a win-win for eco-focused companies.

4) Compatible with airless pumps that protect formulas from contamination—perfect for foundations or serums needing long shelf life.

Aluminum’s minimalist aesthetic also plays well with modern branding trends focused on clean lines and neutral tones.

Eco-friendly cardboard for sustainable eyeshadow palettes

While some think paperboard equals flimsy, today’s high-grade cardboard tells a different story altogether. These palettes are engineered strong enough to hold pans securely while still being biodegradable after use.

Designers love working on them because they’re like blank canvases—ready for silk screening, foil stamping, or textured overlays that pop on social feeds without adding plastic waste into circulation.

More than just recyclable—they’re often made from post-consumer materials too, closing the loop beautifully in cosmetic supply chains aiming toward zero waste goals.

Three Factors Influencing Wholesale Cosmetic Packaging Costs

What really drives up or trims down costs when buying beauty containers in bulk? Let’s break it down by material, finish, and shipping.

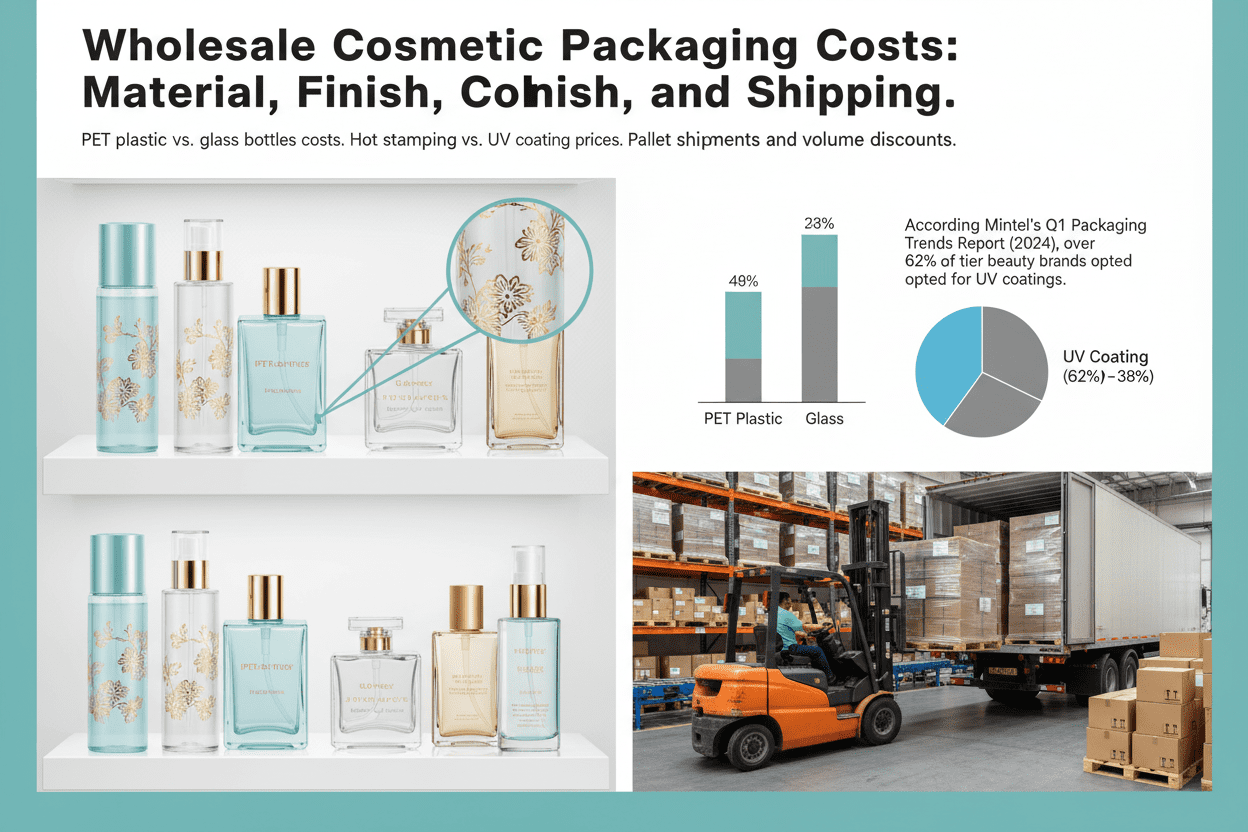

Factor 1 – PET plastic vs. Glass bottles costs

When choosing between PET and glass containers for cosmetics, cost isn’t the only factor—but it’s a big one.

- Material costs: PET is significantly more affordable than glass, especially when ordered in high volumes.

- Durability: Plastic tends to survive transit better—fewer breakages mean lower replacement expenses.

- Weight matters: Glass adds heft, which increases shipping fees due to higher freight weight.

- Sustainability debates: While glass may seem greener, recycled PET options are gaining ground fast.

- Customization potential: Both materials allow for design flexibility, but PET usually offers cheaper mold changes.

If you’re scaling up your skincare line or prepping for a product launch blitz, opting for PET might keep your budget breathing easier without compromising on perceived quality.

Factor 2 – Hot stamping vs. UV coating prices

Design plays a sneaky role in packaging budgets—especially when it comes to finishing touches like hot stamping or UV coating.

• Hot stamping uses heat and foil to create shiny metallic accents—it looks luxe but comes with higher setup fees and longer turnaround times.

• UV coating involves applying a glossy liquid layer that’s cured under ultraviolet light—it’s quicker and more cost-effective per unit for large orders.

Now here’s where things get tricky:

- If you’re producing fewer than 5,000 units, hot stamping might blow your budget out of proportion due to fixed tooling charges.

- On larger runs above that threshold? The price gap narrows slightly—but UV still wins on speed and repeatability.

- According to Mintel’s Q1 Packaging Trends Report (2024), over 62% of mid-tier beauty brands opted for UV coatings over foil embellishments due to better ROI on mid-range SKUs.

So if you’re chasing that premium look without hemorrhaging cash, think twice before going all-in with metallic finishes—especially if you’re still testing the waters with your product line.

Factor 3 – Pallet shipments and volume discounts

Shipping isn’t just about moving boxes—it’s about how smartly you move them.

Bulk buyers who consolidate orders onto pallets unlock serious savings through:

• Lower per-unit freight rates thanks to optimized space usage

• Easier warehouse handling—pallets roll straight into storage or fulfillment lines

• Eligibility for tiered supplier discounts based on total order size

Even better? Many manufacturers throw in perks like free storage periods or reduced lead times once pallet thresholds are hit. That means if you’re ordering thousands of jars or tubes at once—not just hundreds—you’re not just saving money; you’re also streamlining logistics from factory floor to retail shelf.

And while smaller orders might feel safer early on, those who plan ahead often find that pallet-level purchasing pays off faster than expected—with fewer headaches along the way thanks to simplified tracking systems and consolidated invoices tied directly to each shipment batch.

In short: bigger buys bring smarter savings across both transport and supply chain flow.

How Can Wholesale Cosmetic Packaging Reduce Waste?

Small tweaks in packaging can make a massive dent in beauty industry waste. Here’s how smart wholesale choices help brands stay green and savvy.

Refillable oval-shaped blush compacts using dropper caps

— Compact size, big impact: These refillable blush containers cut down on landfill junk by letting users replenish instead of toss.

— The refillable containers are shaped to fit snugly into bags and drawers, making them both eco-smart and user-friendly.

— Dropper caps? Genius move! They reduce mess, save product, and look sleek as heck.

Little design upgrades like these are more than just cute—they’re part of a serious shift toward sustainable packaging that doesn’t skimp on style or function.

Eco-friendly cardboard sleeves with silk screening for reduced scraps

Using cardboard sleeves instead of plastic shells slashes the amount of waste created during production. Silk screening eliminates the need for extra labels or stickers, which often end up as trash anyway. This combo keeps things clean-looking while leaning hard into biodegradable materials, all without sacrificing shelf appeal.

Scenario: Sifter jars and bulk discounts to limit overstock

- Brands buy sifter jars in bulk to avoid unnecessary reorders.

- Bulk orders reduce packaging costs per unit.

- Less overstock means fewer expired products getting tossed.

It’s a win-win: smarter inventory plus less waste from unsold goods cluttering up storage rooms or landfills—all thanks to smart use of wholesale jar options and those sweet wholesale benefits.

Cardboard-based displays made from recycled pulpboard

• Made with post-consumer pulp = lower carbon footprint right outta the gate

• Lightweight yet sturdy = cheaper shipping + fewer breakages

• Printed using eco-friendly inks, so nothing toxic leaches into the supply chain

These displays aren’t just functional—they’re loud-and-proud statements that your brand gives a damn about the planet while still keeping things slick on retail shelves.

Minimalist tube designs with compostable packaging liners

Some tubes now use plant-based liners that break down naturally once tossed—not in centuries but months! Combine that with minimalist branding printed directly onto the surface using soy-based dyes? You’ve got yourself a sleek little package doing double duty: reducing environmental load while looking fresh as ever.

Topfeel’s new line nails this balance perfectly—proof that going minimal doesn’t mean going boring when you pair it with clever use of compostable packaging and reduced material mass across every unit sold.

International Shipping: Lightweight Packaging Benefits

Global shipping is a beast, but smart packaging can tame it. Let’s break down how lighter materials and smarter design keep costs low and efficiency high.

30% lighter PET plastic cylindrical lipstick tubes

- Less weight = lower fuel consumption, which means reduced shipping costs. That’s a win for both your budget and the planet.

- The switch to PET trims excess bulk without compromising durability—ideal for long-haul international movement.

- A lighter load also means fewer emissions, aligning with global sustainability goals.

These tubes aren’t just featherweight—they’re tough enough to protect products from damage during transit, increasing customer satisfaction on arrival.

Oval-shaped aluminum containers for streamlined air freight

• Fit more per crate? Absolutely. Oval shapes reduce dead space, making every inch count.

• Their rigid form resists crushing, offering better protective packaging than many traditional shapes.

• They stack tighter, ship smarter, and ride smoother through customs queues.

Oval containers don’t just look sleek—they’re engineered for max transportation efficiency, especially across international borders where space equals dollars.

Volume pricing tiers and pallet shipments minimize shipping costs

Grouped benefits make this combo unbeatable:

-

Volume Pricing Tiers

• Lower per-unit cost as order size increases.

• Encourages bulk buying without inflating budgets. -

Pallet Shipments

• Streamlined handling cuts labor time at docks.

• Reduces risk of item-level damage—key for fragile goods like cosmetics.

Together, they shrink overall shipping costs while boosting operational ease for wholesale buyers dealing with large-scale orders of cosmetic cases or jars.

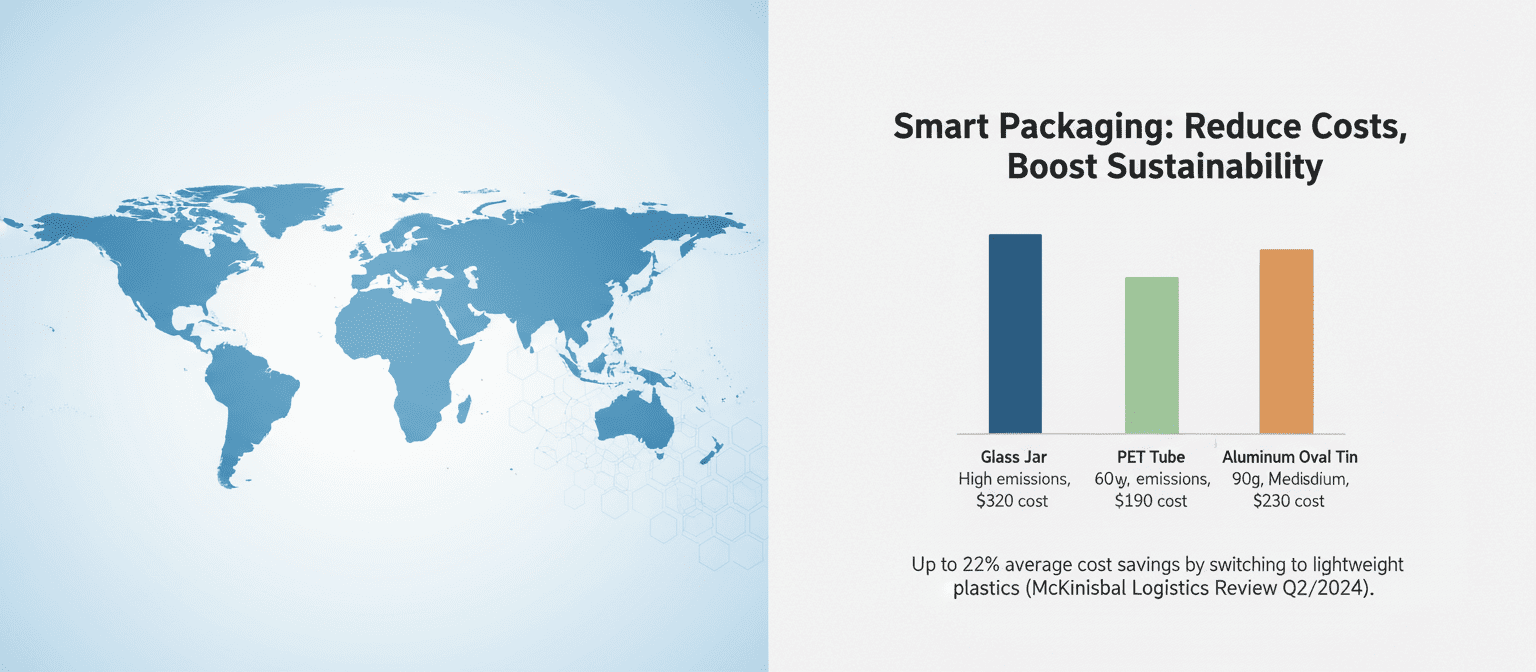

Material selection impacts international freight charges

Material choice isn’t just about aesthetics—it directly affects your bottom line:

“The average cost savings from switching to lightweight plastics is up to 22%, depending on volume,” notes McKinsey Global Logistics Review Q2/2024.

Heavier materials like glass or steel can double freight fees compared to PET or aluminum alternatives. And when you’re moving thousands of units across continents? That adds up fast.

Choosing wisely improves not only cost but also aligns with eco-conscious branding strategies focused on reducing carbon footprints via smarter material use.

Package size optimization reduces void fillers and waste

✦ Smaller packages = less wasted space inside boxes = fewer expensive void fillers needed like foam or air pillows.

✦ Efficient sizing helps cut down on both material usage and overall box dimensions—directly lowering dimensional weight charges used by most global carriers today.

✦ Bonus: reduced waste boosts your brand’s image around sustainability, too.

When form follows function, you get a cleaner package that travels cheaper—and greener—from factory floor to end customer.

How protective packaging prevents product returns during transit

Short answer? It stops the heartbreak before it starts:

• No cracked compacts or shattered blushes arriving at your customer’s door.

• Return rates drop when items arrive intact—which keeps your margins healthy and reviews glowing.

• Smart cushioning protects not only contents but also brand reputation overseas where replacements are costly and slow.

In short bursts of turbulence or rough handling at customs checkpoints, good protection equals peace of mind—and fewer refund requests clogging up support lines later.

Balancing sustainability with cost-effective shipping practices

| Packaging Type | Avg Weight Per Unit | Carbon Emissions/kg | Cost Per Thousand Units |

|---|---|---|---|

| Glass Jar | 180g | High | $320 |

| PET Tube | 60g | Low | $190 |

| Aluminum Oval Tin | 90g | Medium | $230 |

The trick is finding the sweet spot between eco-friendly choices and economic sense:

→ Go too green with heavy biodegradable options? You might spike freight bills.

→ Go too cheap? You risk poor quality that drives up breakage rates.

Striking this balance makes your packaging both kind to Earth and kind to your wallet—a key factor when exploring options across the wholesale cosmetic supply chain landscape globally.

Importance of minimizing damage through efficient transportation design

Let’s walk through how smart design prevents losses:

Step One: Choose shock-resistant formats like oval tins over brittle plastics.

Step Two: Use interlocking trays inside master cartons—keeps things snug even if boxes shift mid-flight.

Step Three: Opt for moisture-barrier coatings if passing through humid climates; nobody likes melted lipstick.

Step Four: Test-drop samples before mass production—you’ll catch weak points early without risking full shipments later on.

With thoughtful planning baked into each layer of the package journey, you’ll avoid costly mishaps that derail timelines—or worse—customer trust overseas.

FAQs

PET plastic is a favorite among brands scaling up because it’s light, strong, and looks clean on shelves. But beyond aesthetics:

- It cuts international shipping costs thanks to its low weight.

- Bulk orders qualify for tiered pricing—more units mean lower per-piece expense.

- Despite being affordable, it holds up well during transport and daily use.

So you’re not just saving money—you’re also avoiding returns from cracked or leaking containers.

Acrylic resin isn’t just about looking good—it’s tough enough to protect formulas but still allows for creative freedom. You can match brand colors exactly and even play with transparency levels. This material gives your mascara tubes that sleek, high-end finish without sacrificing durability during mass production or transit.

More customers want beauty products that reflect their values—and packaging plays a big role:

- Refillable blush compacts cut down on waste over time.

- Cardboard palettes offer earthy textures ideal for natural makeup lines.

- Aluminum tins shine bright while staying fully recyclable.

These aren’t compromises—they’re statements. Your packaging tells your story before anyone opens the lid.

Skincare lives or dies by what’s inside—but if sunlight breaks down active ingredients before they reach someone’s face, you’ve lost them at hello. UV coating acts like invisible armor: shielding serums and foundations from harmful rays while keeping the bottle crystal clear. In short: better protection means fewer complaints—and more return buyers.

Absolutely—especially when margins matter:

- Pallets reduce freight charges by maximizing space efficiency.

- They simplify warehouse handling (less breakage = less loss).

- Consolidated loads often unlock deeper volume discounts across multiple SKUs—from lipstick tubes to sifter jars.

It’s not just logistics—it’s smart business wrapped in shrink wrap.

They do more than save space in landfills—they build loyalty. A customer who buys one compact but refills it three times becomes part of your story long-term. Pairing refillable designs with precise applicators (like dropper caps) adds function to form—and keeps people coming back not out of habit…but love.