How to Choose the Right Tube Lip Gloss for Your Brand

Starting your own beauty line? Then you know the pressure’s on—choosing the right tube lip gloss packaging can make or break the whole vibe. Get it wrong, and you’re staring down leaks, poor shelf life, or worse—bad first impressions. When you’re buying in bulk, every tube counts.

We’ve worked with brand owners who learned the hard way: a great formula isn’t enough if the packaging falls flat. One client lost thousands because their supplier skipped proper sealing tests. Lesson learned: a cheap tube can be a pricey mistake.

“You’d be surprised how many brands come to us after wasting time on flashy samples that didn’t hold up,” says Lily Chen, Senior Packaging Engineer at Topfeel. “We fix that.”

This article’s got your back—from picking the right supplier and solving leak nightmares to meeting regulations and staying under budget.

5 Steps to Selecting Your Ideal Tube Lip Gloss Supplier

A rock-solid supplier isn’t just about price—it’s about compatibility, consistency, and long-term partnership.

Step 1: Compare Tube and Wand Applicator Designs

Spoiler alert: The applicator design isn’t just about looks—it shapes the entire user experience.

Key Points Across Different Dimensions 1. Functionality Fit:

- Squeeze tubes are better for thicker textures like lip balm and hydrating lip gloss.

- Doe-foot wands are ideal for applying pigmented lip oils or precise [suspicious link removed] formulas.

2. Filling and Assembly:

- Squeeze designs are simpler for manufacturers to fill—fewer steps, lower labor cost.

- Wands with caps and rods require extra alignment, adding complexity to production lines.

3. Usage Comfort:

- Some customers love rollerball dispensers for smooth glide and cooling effect—especially for treatments or lip plumpers.

- Others prefer brush-tip applicators for even shimmery gloss application.

4. Storage and Leakage:

- Squeeze tubes are safer for high-viscosity formulations; wand tubes can risk leakage if seal integrity isn’t perfect.

Step 2: Review Emollients and Oils Compatibility

Not all oils and emollients play nice with packaging—formulas might look great now, but wait till three months on a shelf.

-

Emollient-heavy lip glosses (like those using shea oil or jojoba) can migrate through soft packaging walls over time.

-

Certain synthetic oils can react with cheaper plastics, causing leaching that damages the formula.

-

Your tube must pass compatibility tests with key ingredients like hyaluronic acid, glitter blends, or vitamin E.

-

Pro tip: Always request stability data from the packaging supplier during early sampling.

Step 3: Inspect Tube Materials: Waxes and Polymers

You wouldn’t wear a wool coat in a thunderstorm. Same logic applies to tube material selection.

Start with the Basics:

-

PETG offers strong barriers—perfect for long-lasting lipsticks or glosses with waxes.

-

PP (polypropylene) is affordable and recyclable but has low barrier properties, so it suits short-shelf-life products.

Think Barrier & Durability:

-

If your lip gloss contains sensitive oils or light-sensitive emollients, consider multi-layer tubes with aluminum barriers.

-

For lip plumpers or formulas with active tingling agents, select chemically resistant polymers to avoid material degradation.

Little Things Matter:

-

Even cap threads and seals should be compatible with your formula’s viscosity and volatility.

-

Pay attention to tube elasticity—especially if you’re working with solidifying products like lip balm or treatment sticks.

Step 4: Confirm Hydrating and Non-Sticky Attributes

Nobody wants sticky lips, no matter how glossy the finish is.

Hydrating Texture vs. Sticky Sensation

-

A hydrating formula needs the right delivery system to maintain a smooth glide without clumping.

-

Squeeze tubes often work better for gel-based moisturizing lip gloss, ensuring the formula glides evenly.

Comfort in Application

-

If your formula includes hyaluronic acid or vitamin E, avoid narrow-tip applicators—they trap product and reduce comfort.

-

A sheer, glossy finish needs packaging that doesn’t over-dispense or streak the product on lips.

Step 5: Secure Bulk Pricing for Lip Gloss Tubes

It’s not just what you pay—it’s when, how, and with whom.

Negotiation Tactics That Actually Work

-

Lock in your MOQ (Minimum Order Quantity) upfront, but leave room to scale.

-

Discuss multi-shade SKU strategies—can your supplier package different shades in the same run to cut costs?

What Impacts Cost?

-

Dispenser complexity (e.g., rollerballs cost more than basic caps).

-

Material type: PETG is more expensive than LDPE, but offers stronger barriers.

-

Print finish (matte, glossy, metallic) and custom molding can add 5–15% to base price.

Best Practice: Bundle orders across product types—say, tubes for both lip balm and lip serum—to hit volume discounts faster.

Troubleshooting Common Tube Lip Gloss Leakage Issues

Leaky tubes are a killer for customer satisfaction and shelf appeal. This cluster tackles the most common causes—and fixes—for leakage in tube lip gloss packaging.

Identify Leaks in Squeeze Tube Seals

Bad seals are the silent saboteurs of packaging—especially for glossy and hydrating lip products. Here’s how to spot and fix them early:

-

Seal integrity is key: weak thermal sealing leads to microleaks, especially near the crimped end.

-

Visual inspection tools like LED backlighting help detect tube defects before shipping.

-

Tiny holes caused by tube material stress can let air in and product out.

-

Use quality control stages after each batch: pressure testing, seal integrity audits, and real-time tracking.

-

Want peace of mind? Run leak detection using bubble tests or dye penetration once a week during mass production.

A solid hermetic seal = fewer returns, less mess, and way happier clients.

Fix Cap and Dispenser Fit Problems

Loose caps and faulty dispensers don’t just waste product—they scream “cheap.” Here’s how to lock in precision from all angles:

Cap Fit Issues

-

Mismatched threading? Your thread compatibility must match torque specs.

-

Too loose? That’s a closure issue, often caused by over-polished threads.

Dispenser Design Flaws

-

Poor component alignment during assembly leads to misfits and leak paths.

-

Inconsistent plastic flow during molding affects sealing mechanism performance.

Torque Specifications

-

Under-torqued caps pop off in transit.

-

Over-torqued caps stress the neck and crack the tube.

You need a tight seal without turning the cap into a mini dumbbell workout. Precision = professionalism.

Optimize Viscosity for Lip Oil and Lip Balm

If your product’s leaking even with a perfect cap and seal, the culprit’s probably inside the formula. Here’s how to dial in the texture:

-

Lip oil too thin? It’ll run wild unless the flow properties are adjusted with a tighter ingredient ratio.

-

Lip balm too thick? It won’t squeeze smoothly without warming or pre-softening—time to tweak the rheology.

To get things flowing right:

-

Adjust product viscosity with safe polymers that don’t clash with flavor oils or active ingredients.

-

Match packaging style to thickness. Light oils love drop dispensers, but thicker balms need wide-mouth squeeze tubes.

-

Run small-batch tests—your goal is smooth glide, no post-closure oozing.

Perfect viscosity = less mess, more glam.

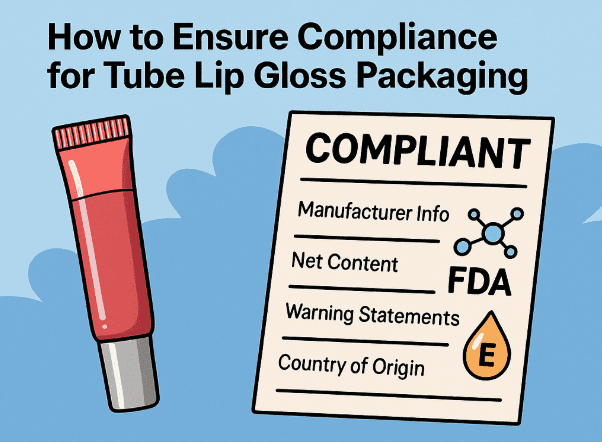

How to Ensure Compliance for Tube Lip Gloss Packaging

Labeling Requirements for Lip Gloss and Lipstick

Clear labeling keeps your brand on the safe side and makes your packaging feel legit. Here’s what should always appear:

-

INCI Names: Ingredients must be listed using standardized cosmetic nomenclature.

-

Net Content: Display volume or weight (e.g., 8ml or 0.27oz).

-

Manufacturer Info: Include brand address and contact details.

-

Warning Statements: Flammable gloss? Allergy-prone ingredients? Say it up front.

-

Country of Origin: Be transparent—buyers want to know where it’s made.

-

FDA Guidelines: U.S. brands must align with FDA cosmetic labeling rules.

Skip one of these? You’re risking a product recall or legal warning.

Material Safety: FDA-Approved Polymers and Waxes

The tube may look pretty, but if it’s not FDA-compliant, it’s a lawsuit waiting to happen. Here’s how to vet your materials:

Step 1: Confirm all raw materials are cosmetic grade and non-toxic.

Step 2: Ask your supplier for toxicology reports, especially for polymers.

Step 3: Match wax and polymer specs with FDA safety standards.

Step 4: Ensure biocompatibility with gloss ingredients like oils and shimmer.

“We reject any packaging that fails polymer stability tests—even if it saves money.” — Lisa Meng, Senior Product Engineer, Topfeel Packaging

Traceability of Hyaluronic Acid and Vitamin E

Traceability is your secret weapon for high-end branding and compliance. Here’s how to get it right from every angle:

-

Supply Chain Transparency: Choose partners with end-to-end traceability tech for ingredient sourcing.

-

Batch Tracking: Require batch IDs for every shipment of hyaluronic acid and vitamin E.

-

Origin Verification: Get proof of where and how each key ingredient was produced—especially if labeled “natural” or “vegan”.

-

Quality Control: Test raw ingredients upon arrival to ensure consistency across gloss tubes.

Inconsistent sourcing kills trust. Bulletproof traceability boosts your reputation and margins.

Budget-Friendly Tube Lip Gloss Options Compared

Polymer-Based Tubes and Squeeze Applicators

These tubes are the go-to for budget brands wanting flexibility, efficiency, and clean dispensing.

-

Why these work:

-

PE/PP materials are super affordable and recyclable.

-

Squeeze applicators make product control easier for end-users.

-

Plastic packaging is lightweight—cutting down freight costs.

-

Flexible tubes don’t crack during filling or transit.

-

-

Form compatibility:

-

Works great with glossy lip treatments and pigmented lip oils.

-

Keeps sheer gloss textures from spilling or drying out.

-

Mini Cost-Performance Chart

| Tube Type | Avg. Cost/Unit | Shelf Life (Years) | Suitability |

|---|---|---|---|

| Mono PE Tube | $0.08 | 2–3 | Lip gloss |

| Co-extruded Tube | $0.10 | 3–4 | Lip balm |

| Laminated Tube | $0.12 | 4–5 | Lip oil |

These plastic warriors strike a sweet spot between price, performance, and form factor. Ideal for brands looking to scale affordably.

Low-Cost Aluminum Caps and Dispensers

Want your packaging to look chic without making your accountant cry? Aluminum caps and flip-tops might be the secret weapon.

-

Twist-off and flip-top aluminum caps are among the cheapest stylish upgrades—ideal for bulk production.

-

Combine metal closures with PE tubes for a sleek, elevated look on a budget.

-

Use these cost-effective dispensers to match everything from sheer lip gloss to thick lip plumper formulas.

Short Tip Series:

-

Go Matte Finish: Looks premium, hides fingerprints.

-

Watch the Thread Fit: Ensure smooth opening for thick balms.

-

Lightweight is Right: Bulk orders = lower shipping fees.

-

Test for Corrosion Resistance: Especially with vitamin E-infused glosses.

Bottom line: these caps check the boxes for durability, looks, and cost.

Affordable Bulk Orders for Lip Stain Packaging

Ordering big doesn’t mean quality has to dip—you just need a few insider moves.

3 Smart Moves to Slash Costs:

-

Consolidate packaging components — Fewer SKUs = faster production and lower mold costs.

-

Opt for high-MOQ suppliers — They often provide serious volume discounts.

-

Leverage private label packaging — Already-in-stock lip stain containers = low tooling fees.

Also, streamline your supply chain. Work with regional vendors who offer warehousing or kitting services—this ensures your cost-saving strategies don’t backfire with hidden logistics fees.

Conclusion

Picking the right tube lip gloss for your brand isn’t just about color and shine—it’s about making smart, scalable Sustainable Cosmetic Packaging choices that won’t leave you stuck with costly mistakes. We’ve walked through supplier vetting, material mishaps, compliance traps, and cost-saving moves, all tuned for those buying big and thinking bigger.

By now, you’ve got the cheat codes to avoid the usual headaches:

- No more leaky caps or mystery ingredients

- Packaging that plays nice with lip oils, stains, and plumpers

- Lower per-unit costs without skimping on quality or vibe

Think of us like your packaging wingman—ready to help you avoid drama and build something people want to reach for. Ready to roll? Hit us up for samples or a quick quote.

As packaging guru Stacy Benton once said, “The tube isn’t just a container—it’s your brand’s handshake.” Make it firm, clean, and unforgettable.

FAQs

What are common tube materials used for lip gloss packaging?

- LDPE: squeezable, budget-friendly

- PET: clear look, sturdy

- Multi-layered polymers: block air for actives like vitamin E

What’s the minimum order quantity for custom cosmetic packaging?

- Standard tubes: 5,000–10,000 units

- Custom molds: 20,000+ units

- Special finishes often need higher runs

How do you prevent separation in lip oil packaged in tubes? Try trial runs with your tube material—adding small amounts of wax or polymers helps stop oils from separating.

Why does my lip balm in squeeze tubes feel too thick to apply?

- Waxes harden in chill

- Tight nozzles block thick balm

- Stiffer tubes need more squeeze

What’s the best packaging for long-lasting lip stains? Lip stains fare best in PET tubes or wand packs—they resist dyes and keep colors true without drying out.

Can I mix matte and glossy lip formulas in one tube format? Matte mixes thick fillers that suit stiff tubes, while glossier blends need softer packs—combining them risks texture and flow.